Silica washing and screening device and method

A technology of screening device and drainage device, which is applied in the direction of chemical instruments and methods, sieving, wet separation, etc., can solve the problems of difficult slag discharge, waste of water source, inability to wash and sieve silica, and achieve stability and smelting The effect of quality assurance and cleanliness assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

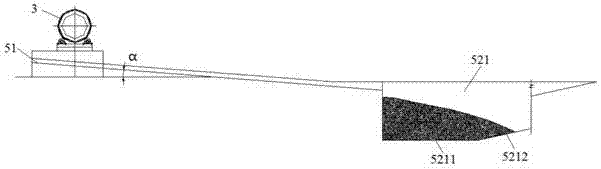

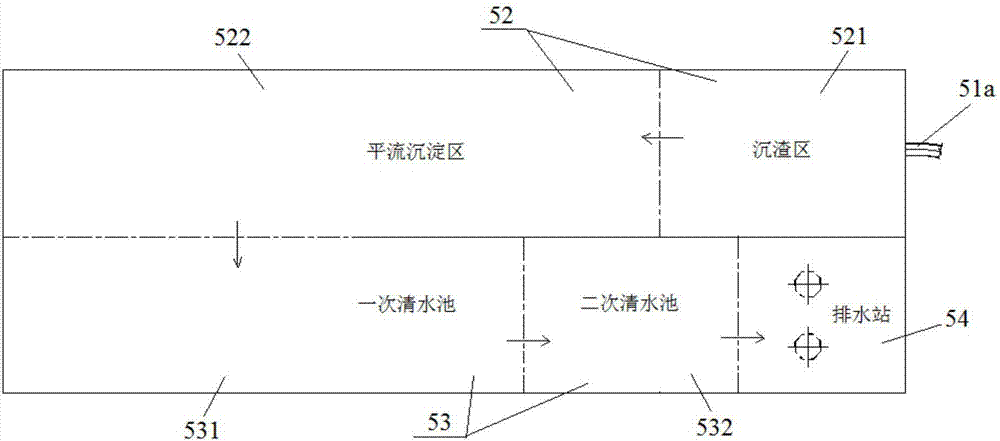

[0036] figure 1 It is a structural schematic diagram of a silica washing and screening device according to the present invention. The silica washing and screening device includes a feeding device 1, a conveying device 2, a water washing and screening device 3, and a slag discharge and drainage device 5 arranged in sequence. The water washing and screening device 3 includes a The screening cylinder 31 and the spray nozzle 32 for washing the silica raw material in the screening cylinder 31 at least at the opening of the screening cylinder 31, the peripheral wall of the screening cylinder 31 is provided with an open ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com