Heating control method of bowl-washing machine

A technology of heating control and control method, which is applied in energy-saving heating/cooling, tableware washing machine/rinsing machine, tableware washing machine/rinsing and rinsing machine parts, etc., which can solve the problems of high consumption, high energy consumption, and high cost. Reach the effect of reducing energy consumption and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

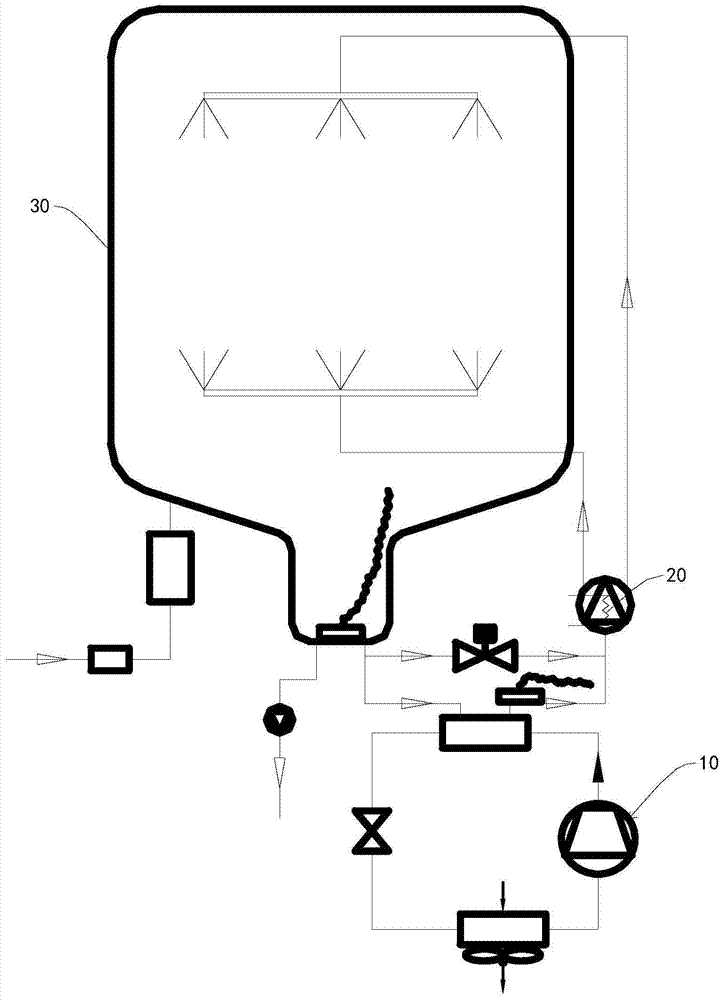

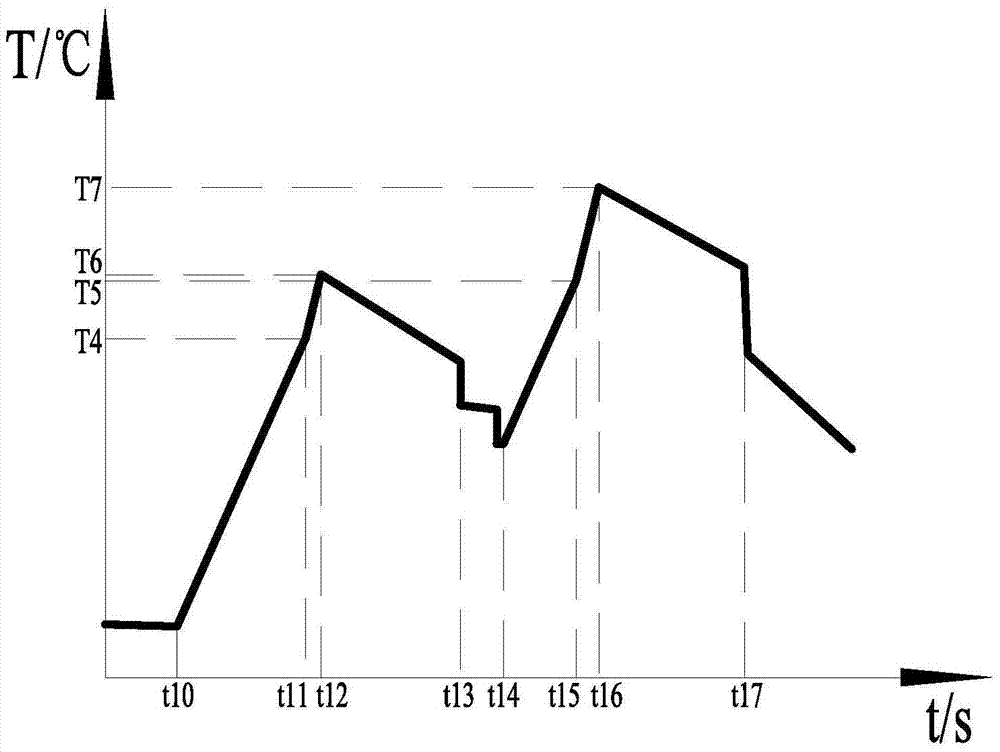

[0036] Such as figure 2 As shown, the heat pump system 10 and the auxiliary heating system 20 are switched on sequentially during the main washing phase; the heat pump system 10 and the auxiliary heating system 20 are switched on sequentially during the main rinsing phase.

[0037] Specifically, before t10 is the pre-washing stage, the heat pump system 10 and the auxiliary heating system 20 are not started, t10-t13 is the main washing stage, the running time of the heat pump system 10 is t11-t10, with the help of the circulating washing water heat transfer medium. The interior of the washing chamber is heated to T4°C, and the range of T4 is 40-60. The operation time of the auxiliary heating system 20 is t12-t11. The interior of the washing chamber 30 is heated to T6°C by means of the circulating water heat transfer medium, and then recirculated for a certain period of time. Drain until time t13.

[0038] T13-t14 is the pre-rinsing stage, heat pump system 10 and auxiliary hea...

Embodiment 2

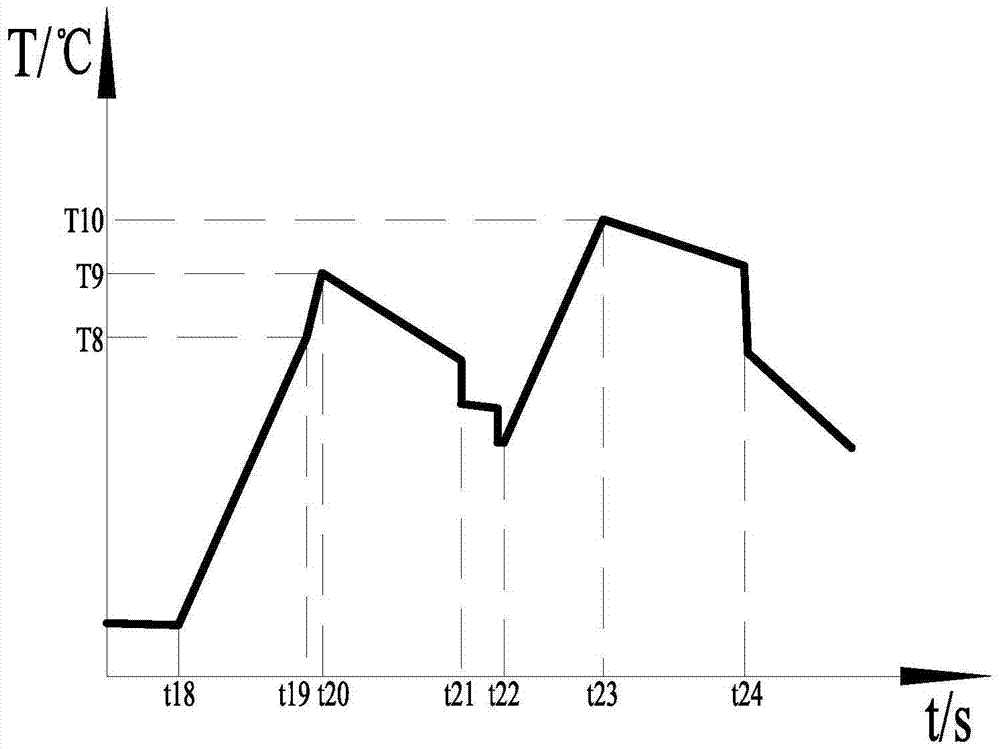

[0041] Such as image 3 As shown, when in the main washing stage, the heat pump system 10 and the auxiliary heating system 20 are switched on sequentially; when in the main rinsing stage, only the heat pump system 10 is started.

[0042] Specifically, before t18 is the pre-wash stage, heat pump system 10 and auxiliary heating system 20 are not started, t18-t21 is the main wash stage, heat pump system 10 is running for t19-t18, and the heat pump system 10 is used for washing by means of circulating water heat transfer medium. The interior of the chamber 30 is heated to T8°C, and the auxiliary heating system 20 is operated for t20-t19, and the interior of the washing chamber 30 is heated to T9°C by means of the circulating water heat transfer medium, which is recirculated for a certain period of time and drained until t21.

[0043] T21-t22 is the pre-rinsing stage, heat pump system 10 and auxiliary heating system 20 are not started, t22-t24 is the main rinsing stage, and the run...

Embodiment 3

[0046] Such as Figure 4 As shown, when in the main washing stage, the heat pump system 10 and the auxiliary heating system 20 are switched on sequentially; when in the main rinsing stage, only the auxiliary heating system 20 is started.

[0047] Specifically, before t25 is the pre-wash stage, heat pump system 10 and auxiliary heating system 20 are not started, t25-t28 is the main wash stage, heat pump system 10 is running for t26-t25, and the heat pump system 10 is used for washing by means of circulating water heat transfer medium. The interior of the chamber 30 is heated to T11°C, and the auxiliary heating system 20 is operated for t27-t26. The interior of the washing chamber 30 is heated to T12°C by means of the circulating water heat transfer medium, recirculated for a certain period of time and drained until t28.

[0048] T28-t29 is the pre-rinsing stage, the heat pump system 10 and the auxiliary heating system 20 are not started, t29-t31 is the main rinsing stage, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com