Battery test apparatus and battery test method

A battery test and battery technology, applied in the direction of secondary battery test, measuring device, impact test, etc., can solve the problems of increasing the cost of the device, waiting for a long time, increasing the installation space, etc., to achieve rapid and safe processing, suppressing the device Effect of increased cost and installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0026] [Battery Test Device]

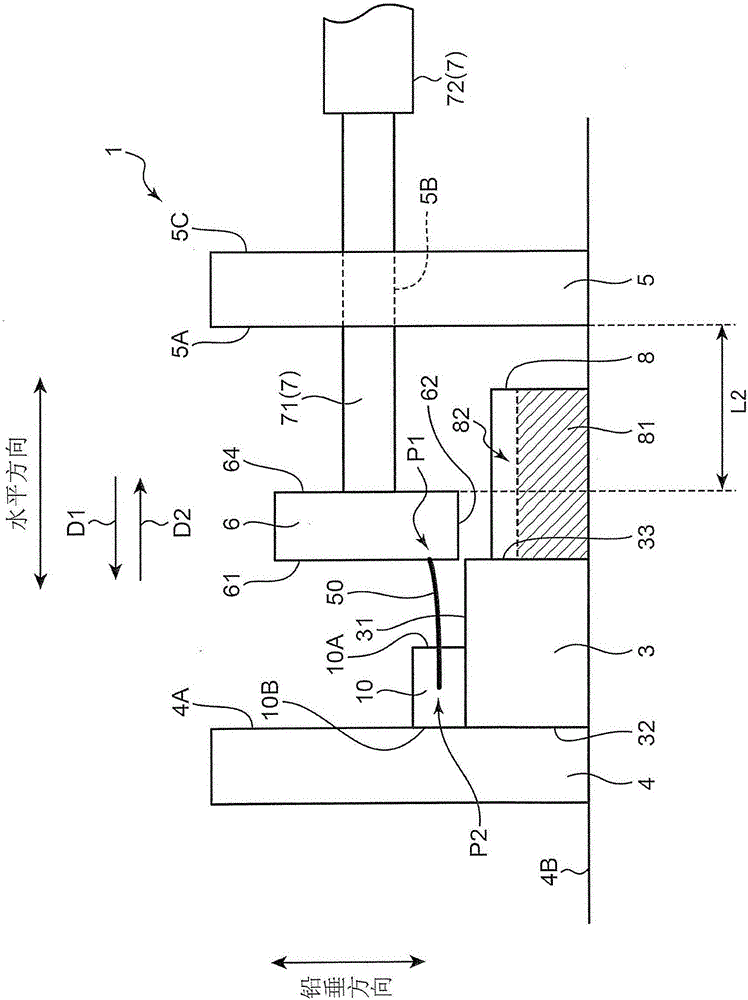

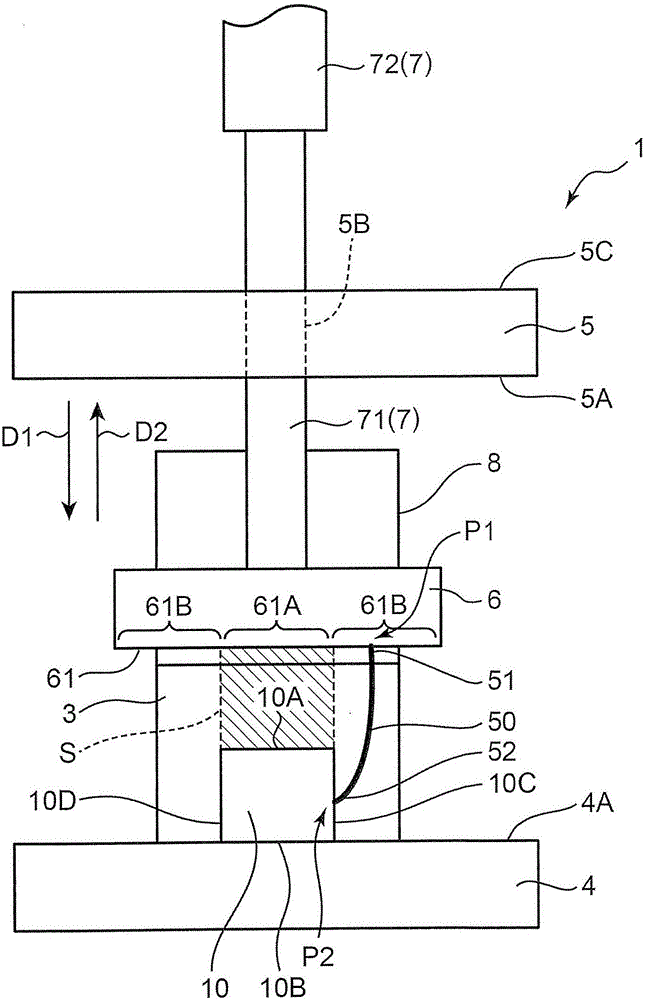

[0027] First, refer to figure 1 The configuration of the battery test device 1 according to Embodiment 1 of the present invention will be described. figure 1 The overall configuration of the battery testing device 1 is schematically shown. figure 1 The horizontal direction is the horizontal direction, and the vertical direction is the gravity direction (vertical direction).

[0028] The battery testing device 1 is a device for performing a crush test of a battery 10 that is a secondary battery for vehicles, such as a lithium ion battery. The squeeze test is one of the safety performance tests of the battery 10. Specifically, in the squeeze test, an internal short circuit is suspected to have occurred by applying a specified pressure to the battery 10, and the voltage and temperature changes at this time are detected, or by The safety performance of the battery 10 is confirmed by external observation to confirm whether the battery 10 catches fi...

Embodiment approach 2

[0063] Below, refer to Figure 7 A battery testing device 1A according to Embodiment 2 of the present invention and a battery testing method using the battery testing device 1A will be described. Embodiment 2 is basically the same as Embodiment 1, but differs from Embodiment 1 in that battery moving unit 50 is constituted by clip member 53 and coupling member 54 . Hereinafter, only the configuration of the battery transfer unit 50 that is different from the first embodiment will be described in detail.

[0064] Such as Figure 7 As shown, the battery moving unit 50 includes: a clamp member 53 having an L-shape in side view; and a connecting member 54 connecting the clamp member 53 and the pressurizing part 6 (pressurizing surface 61 ) to each other. In Embodiment 2, one end of the connecting member 54 is connected to the pressurizing surface 61 , and the other end is not directly connected to the battery 10 .

[0065] The clamp member 53 rests on the setting surface 31 Fi...

Embodiment approach 3

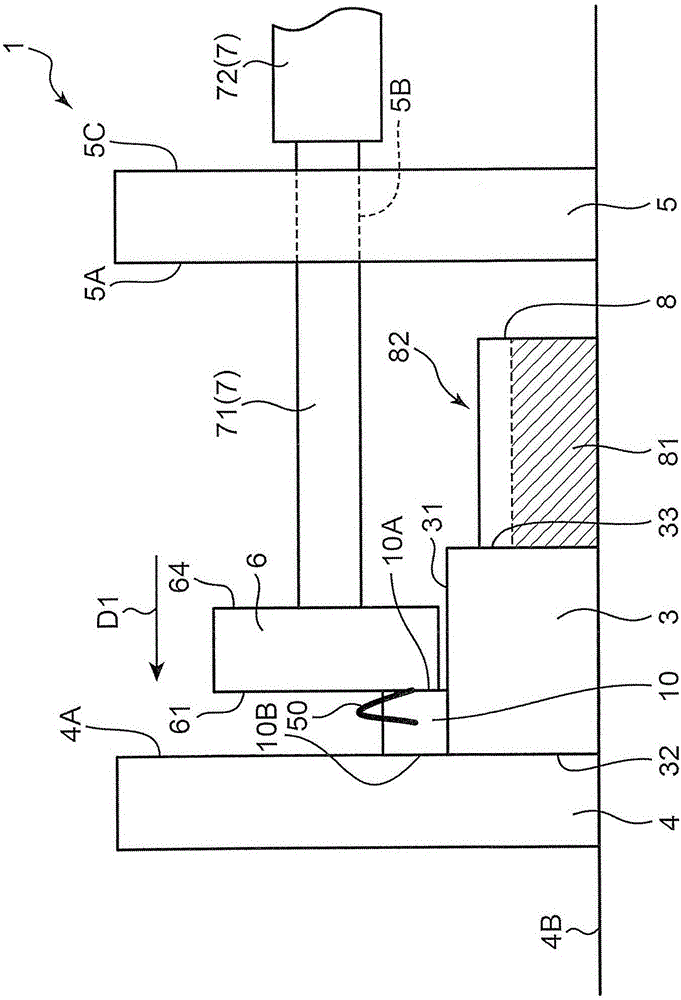

[0075] Below, refer to Figure 9 A battery test device according to Embodiment 3 of the present invention will be described. Embodiment 3 is basically the same as Embodiments 1 and 2, but is different from Embodiments 1 and 2 in that the nail penetration test is performed.

[0076] Figure 9 The pressurizing part 6 and its vicinity in the battery testing device are shown enlarged. Such as Figure 9 As shown, a nail portion 63 for piercing through the battery 10 is provided on the pressing surface 61 of the pressing portion 6 . Therefore, the nail portion 63 can be pierced through the battery 10 by moving the pressurizing portion 6 in a direction approaching the battery 10 based on the driving of the driving portion 7 . Accordingly, it is possible to perform a nail penetration test in which an internal short circuit occurs in the battery 10 and changes in temperature and voltage at that time, the appearance of the battery 10 , and the like can be confirmed.

[0077] Then, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com