Thick copper foil shape correcting FPC having pierced gold fingers and manufacturing technology thereof

A manufacturing process and golden finger technology, which is applied in the manufacture of printed circuits, the formation of electrical connections of printed components, printed circuits, etc., can solve problems such as solder joints that cannot be connected or poor contact, product failure and scrapping, and affect accuracy, so as to avoid Poor connection, improved product reliability, and cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing and example.

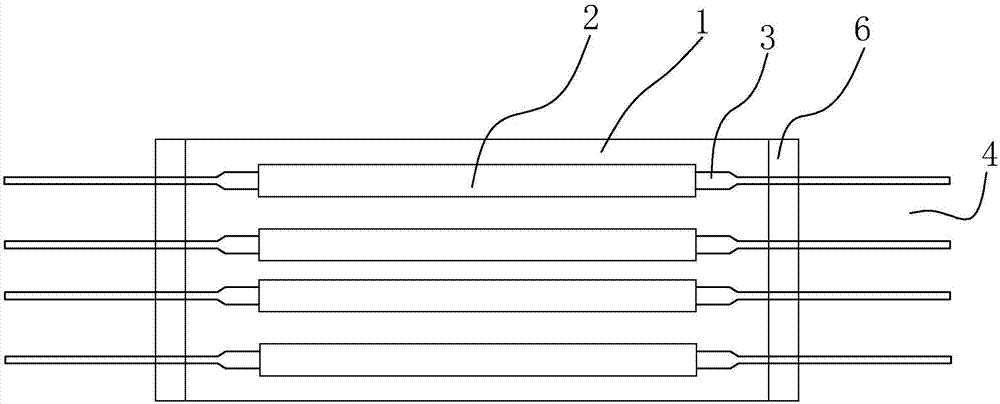

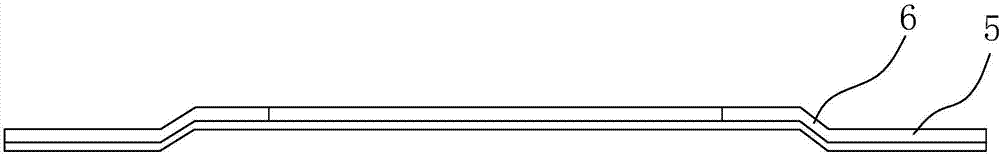

[0023] like figure 1 and figure 2 As shown, a thick copper foil orthopedic FPC with hollow 4 gold fingers of the present invention includes a substrate 1, a copper foil circuit 2 printed on the substrate 1 and a gold finger 3, and the copper foil circuit 2 is etched form. The gold fingers 3 are arranged on both sides of the base material 1, the gold fingers 3 have an inner end connected to the circuit and an outer end extending to the edge of the base material 1, and the FPC is provided with a stamping formed in the gold finger 3 area. Concave step 5, to achieve orthopedic effect. The present invention releases the internal stress of the FPC through the concave step 5, so that the thick copper FPC is not easy to expand or shrink and deform, avoiding poor connection caused by the strain of the solder joints of the product during use in different environments,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com