Lenticular lens array element

A lens array and component technology, applied in the direction of lenses, optical components, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

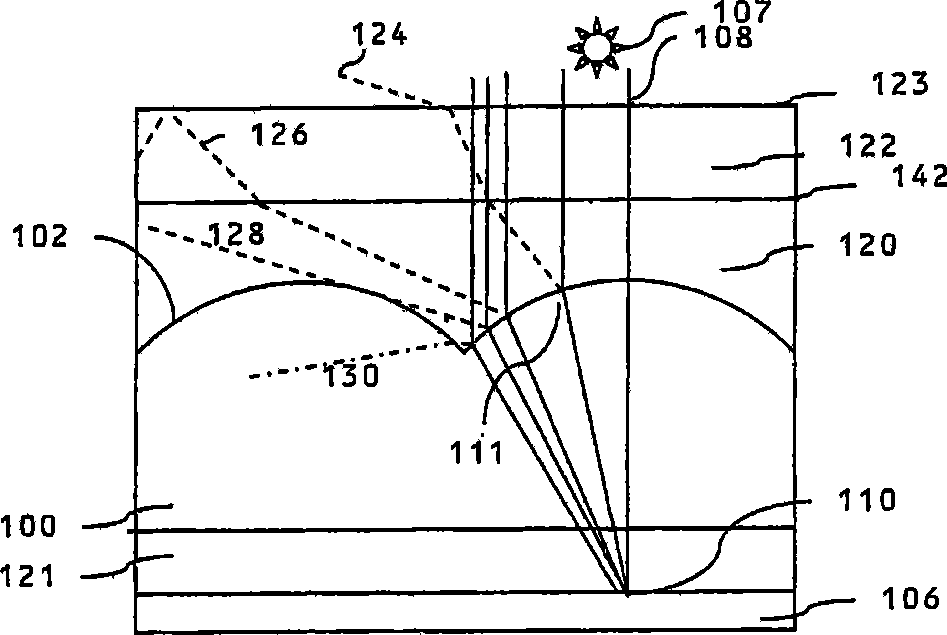

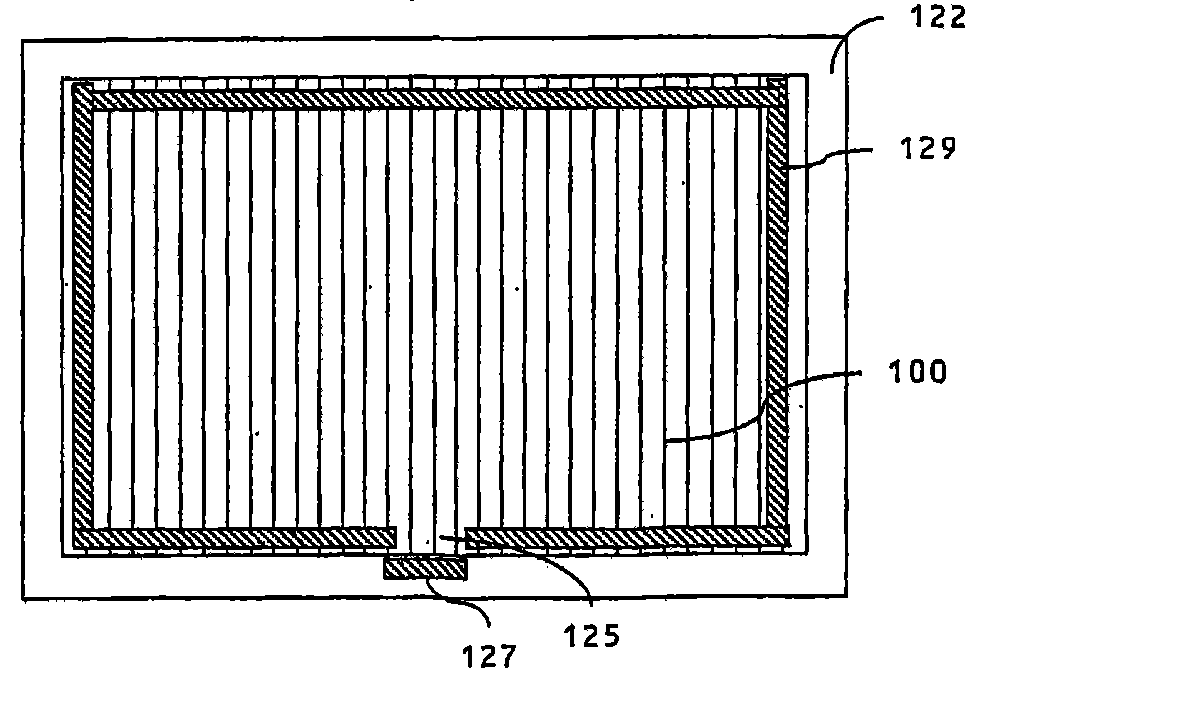

[0162]The various arrangements described below contain a number of common building blocks. Common components are given the same reference numbers. For the sake of brevity, descriptions of common components are not repeated, but any discussion of a component applies to all embodiments in which it appears.

[0163] Here, first, a directional printing image display apparatus using a lens member according to the present invention will be described.

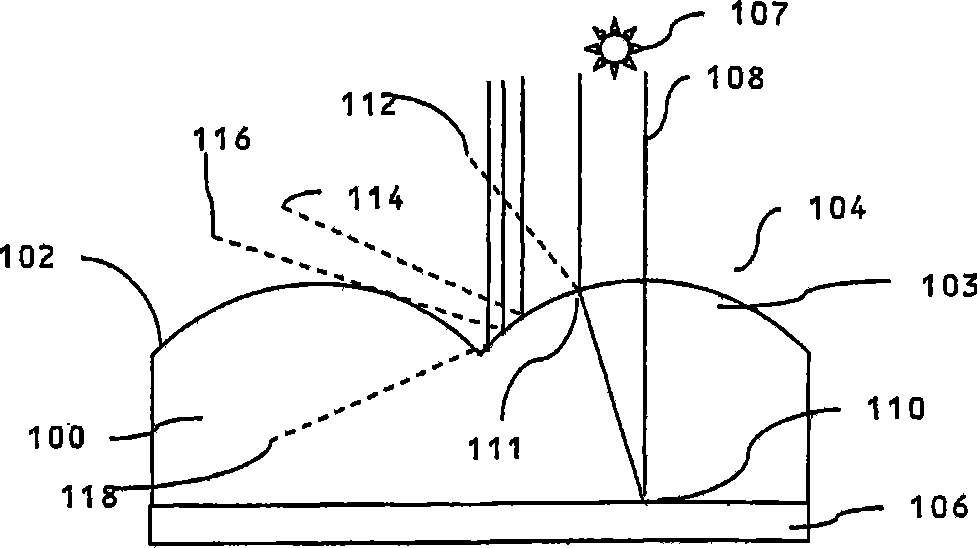

[0164] figure 1 A directional printed image display device utilizing a known type of lens array is shown. A lens structure comprises a substrate 100 whose front surface 102 has a surface relief shaped as a cylindrical lens array surface. The front surface 102 constitutes an interface between the substrate 100 and air 104 . Each of the lens surfaces can thus be regarded as a section of the surface relief, which provides a lens effect, and the lens member constitutes a lens array.

[0165] In this specification, the term "cylindric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com