LED epitaxial wafer and preparation method therefor

An LED epitaxial wafer and reaction chamber technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of low radiation recombination probability, low internal quantum efficiency, low luminous efficiency, etc., and achieve high hole concentration, high mobility, The effect of improving the injection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] It is roughly the same as Comparative Example 1, except that the p-type layer of Comparative Example 1 is changed to p-type AlGaN whose Al composition is gradually reduced from 0.3 to 0.05 by using polarization-induced doping technology, and the thickness is also 90nm, and has Same average Al composition as Comparative Example 1.

Embodiment 2

[0041] It is substantially the same as Example 1, except that the p-type AlGaN layer whose Al composition is gradually changed from 0.3 to 0.05 in Example 1 is split into two 45nm p-type AlGaN polarization-induced doping graded layers, each The Al composition of the layers is gradually changed from 0.3 to 0.05, so the average Al composition is the same as that of the previous embodiment 1.

Embodiment 3

[0043] It is substantially the same as in Example 1, except that the p-type AlGaN layer whose Al composition is gradually changed from 0.3 to 0.05 in Example 1 is split into three 30nm p-type AlGaN polarization-induced doping graded layers, each The Al composition of the layers is gradually changed from 0.3 to 0.05, so the average Al composition is the same as that of the previous embodiment 1.

[0044] figure 1 It is a schematic structural diagram of the P-type layer of Examples 1-3 and Comparative Example 1.

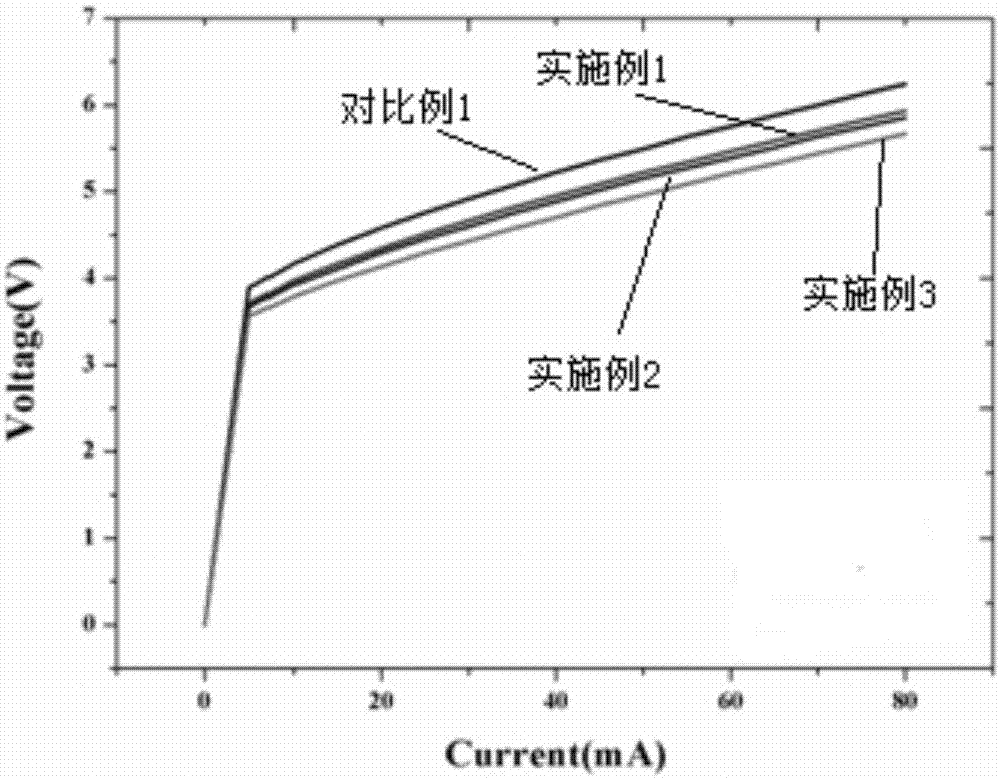

[0045] figure 2 It is the current-voltage curve diagram of three embodiments and Comparative Example 1. We can find that the forward voltage of Examples 1-3 is lower than that of Comparative Example 1. The results show that the forward voltage of the UV LED can be significantly reduced when the p-type layer is made by polarization-induced doping technology, which indicates that the p-type layer has lower resistivity than the ordinary p-type layer. And since the p-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com