A kind of sulfur-doped mxene material and its preparation method and application

A technology of sulfur doping and sodium sulfide, applied in the field of nanomaterials, can solve the problems such as the specific capacitance and capacitance need to be improved, and achieve the effects of simple preparation method, improved specific capacity and cycle stability, and controllable doping content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The present embodiment provides a kind of preparation method of sulfur-doped MXene material, comprises the following steps:

[0051] Step 1, preparation of two-dimensional Ti 3 C 2 Material: take 5g Ti 3 AlC 2 , add 40ml of 40% HF solution with a mass fraction, stir at room temperature for 3h, then centrifuge, remove the lower layer of solid, wash with deionized water, and centrifuge several times until the supernatant pH=6-7, remove the lower layer of solid, and place Vacuum drying at 50°C for 24 hours to obtain Ti 3 C 2 Material;

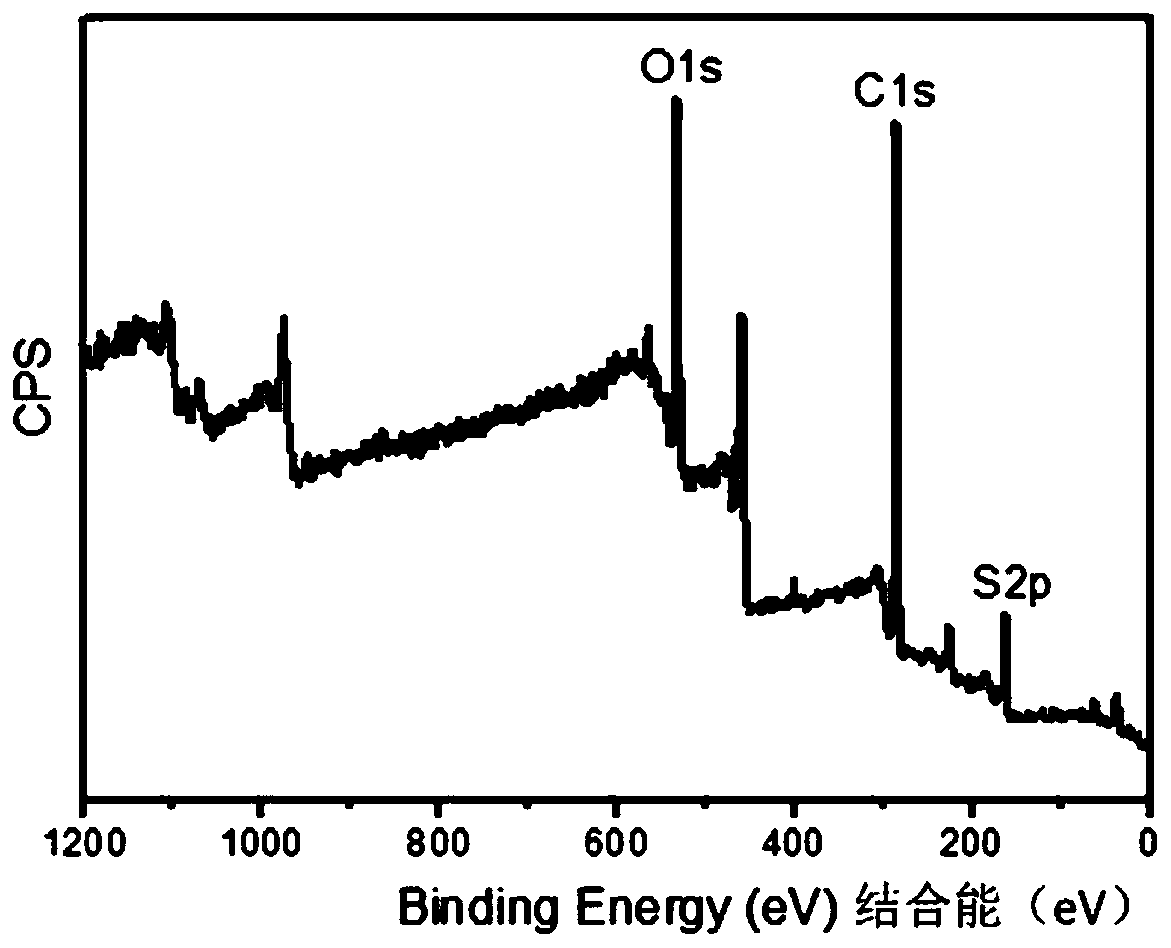

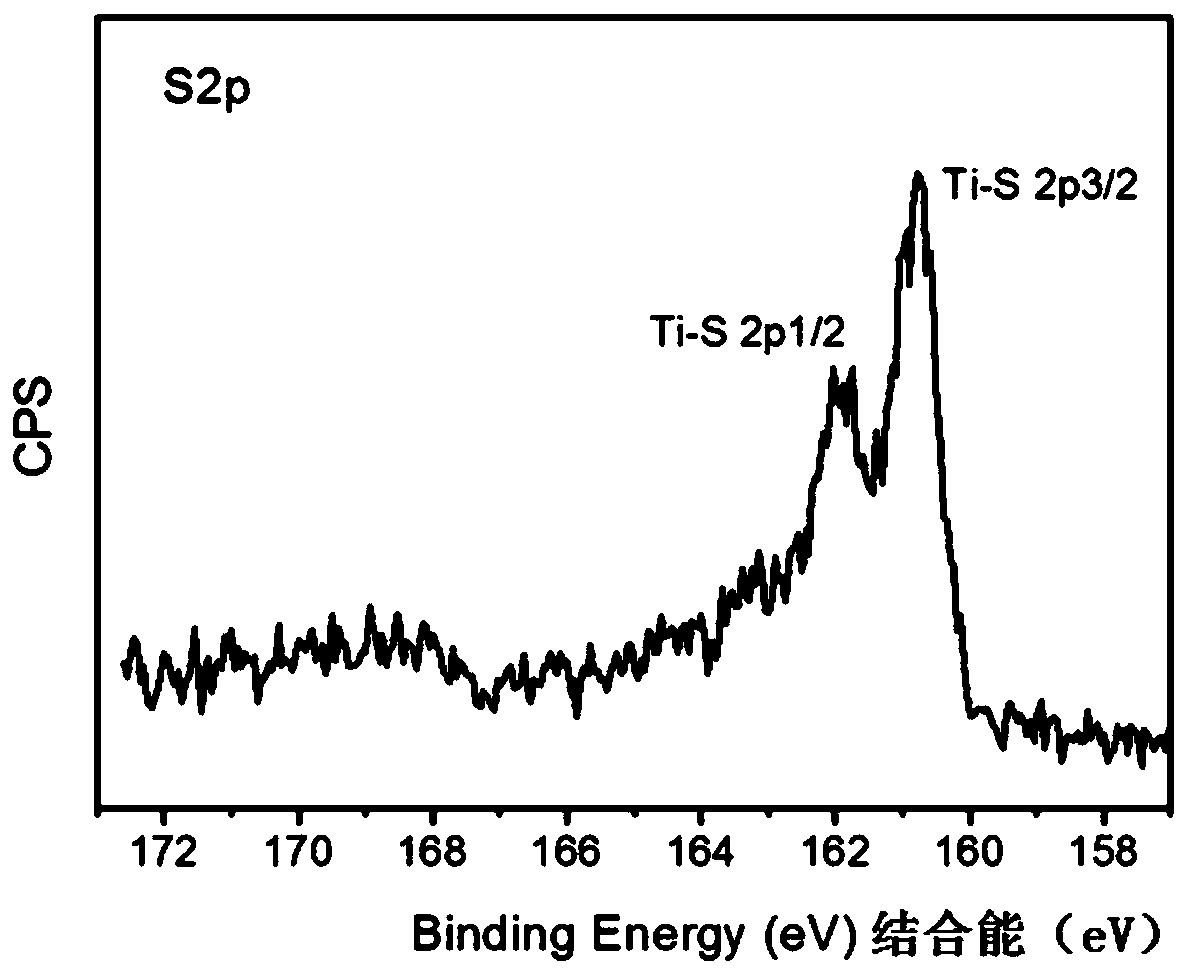

[0052] Step 2, preparing sulfur-doped Ti 3 C 2 Material: Take 1g Ti 3 C 2 The material is put into the tube furnace, and H 2 S gas, the flow rate is controlled at 100ml / min, and then the temperature is raised to 700°C for heat treatment for 2h, and then the tube furnace is lowered to room temperature, and the sample is taken out to obtain sulfur-doped Ti 3 C 2 Material.

[0053] For the sulfur-doped Ti prepared in this example ...

Embodiment 2

[0063] The present embodiment provides a kind of preparation method of sulfur-doped MXene material, comprises the following steps:

[0064] Get 1g embodiment 1 to prepare Ti 3 C 2 The material is put into the tube furnace, and H 2 S gas, control its flow rate to 100ml / min, then raise the temperature to 500°C for heat treatment for 2h, then lower the tube furnace to room temperature, take out the sample, and obtain sulfur-doped Ti 3 C 2 Material.

[0065] For the sulfur-doped Ti prepared in this example 3 C 2 Materials are characterized as Figure 4 As shown in the scanning electron microscope figure, the sulfur-doped Ti prepared in this embodiment 3 C 2 The material is a layered structure with an atomic doping content of 1.03% of sulfur atoms and a specific surface area of 50m 2 / g.

[0066] Adopt the method for embodiment 1 to make the sulfur-doped Ti that the present embodiment makes 3 C 2 The materials were made into working electrodes and used in supercapacit...

Embodiment 3

[0069] The present embodiment provides a kind of preparation method of sulfur-doped MXene material, comprises the following steps:

[0070] Get 1g embodiment 1 to prepare Ti 3 C 2 The material is put into the tube furnace, and H 2 S gas, control its flow rate to 100ml / min, then raise the temperature to 900°C for heat treatment for 2h, then cool down the tube furnace to room temperature, take out the sample, and obtain sulfur-doped Ti 3 C 2 Material.

[0071] For the sulfur-doped Ti prepared in this example 3 C 2 Materials are characterized as Figure 5 As shown in the scanning electron microscope figure, the sulfur-doped Ti prepared in this embodiment 3 C 2 The material is a layered structure with an atomic doping content of sulfur atoms of 11.70% and a specific surface area of 34m 2 / g.

[0072] Adopt the method for embodiment 1 to make the sulfur-doped Ti that the present embodiment makes 3 C 2 The materials were made into working electrodes and used in superca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com