Sintering flue gas circulation low NOx emission process

A technology for sintering flue gas and flue gas, which is applied in the field of flue gas denitration process and low NOx emission process of sintering flue gas circulation, can solve the problems of insignificant energy saving and emission reduction effect, quality separation cycle, flue gas zoning, etc. Market application prospects, the effect of reducing drag loss and reducing efflux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

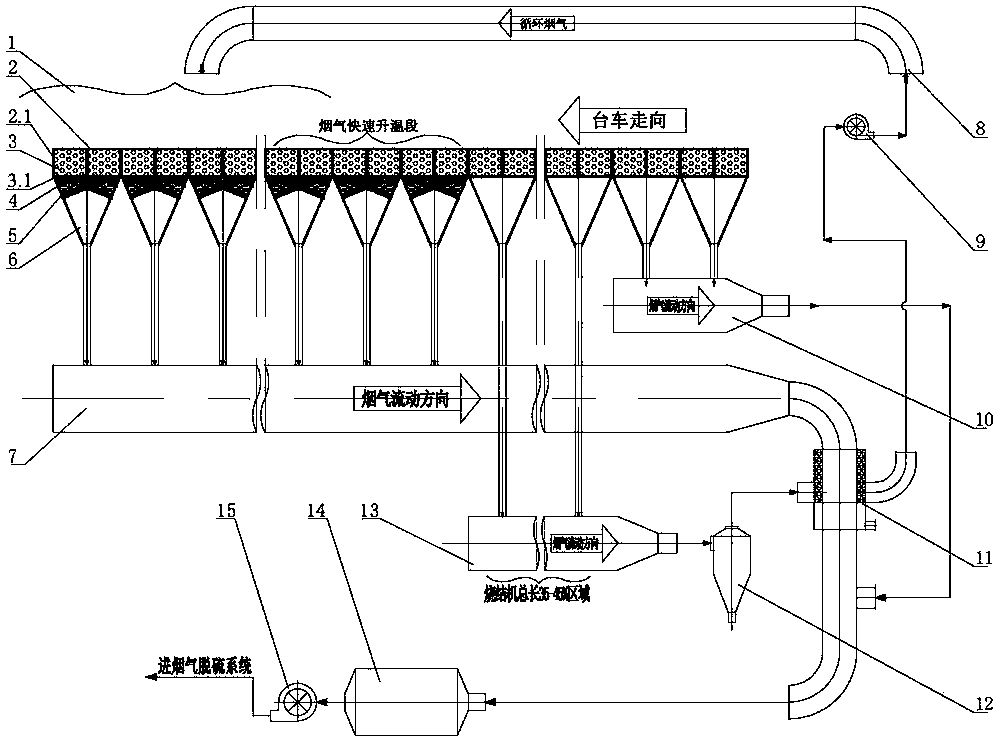

[0030] Referring to Fig. 1, the present invention includes a sintering machine 2, a bellows 6 is provided under the trolley 2.1 of the sintering machine 2, and the outlet at the bottom of the bellows 6 is connected to the flue pipe, and the sintering machine is successively divided into an ignition section, a machine There are 4 areas: the head section, the flue gas rapid heating section and the tail section. The air box 6 below the tail section to the flue gas rapid heating section area is equipped with a liquid ammonia nozzle 4; the flue gas pipeline includes the main flue 7. The main flue 13 of the circulating flue gas and the flue 10 of the ignition section of the machine head, the outlet of the bellows 6 below the tail section and the rapid heating section of the flue gas are connected to the main flue 7, and the outlet of the main flue 7 passes through the circulating flue gas The tube side or shell side of the heat exchanger 11 is connected to the electrostatic / bag filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com