Turnover powder coating drying equipment

A technology for drying equipment and powder coatings, which is applied in drying, drying machines, lighting and heating equipment, etc. It can solve the problems of incomplete drying and long drying time of powder coatings, so as to avoid uneven drying, The effect of preventing accumulation and convenient discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0028] The present invention will be described in detail below with reference to the accompanying drawings and examples.

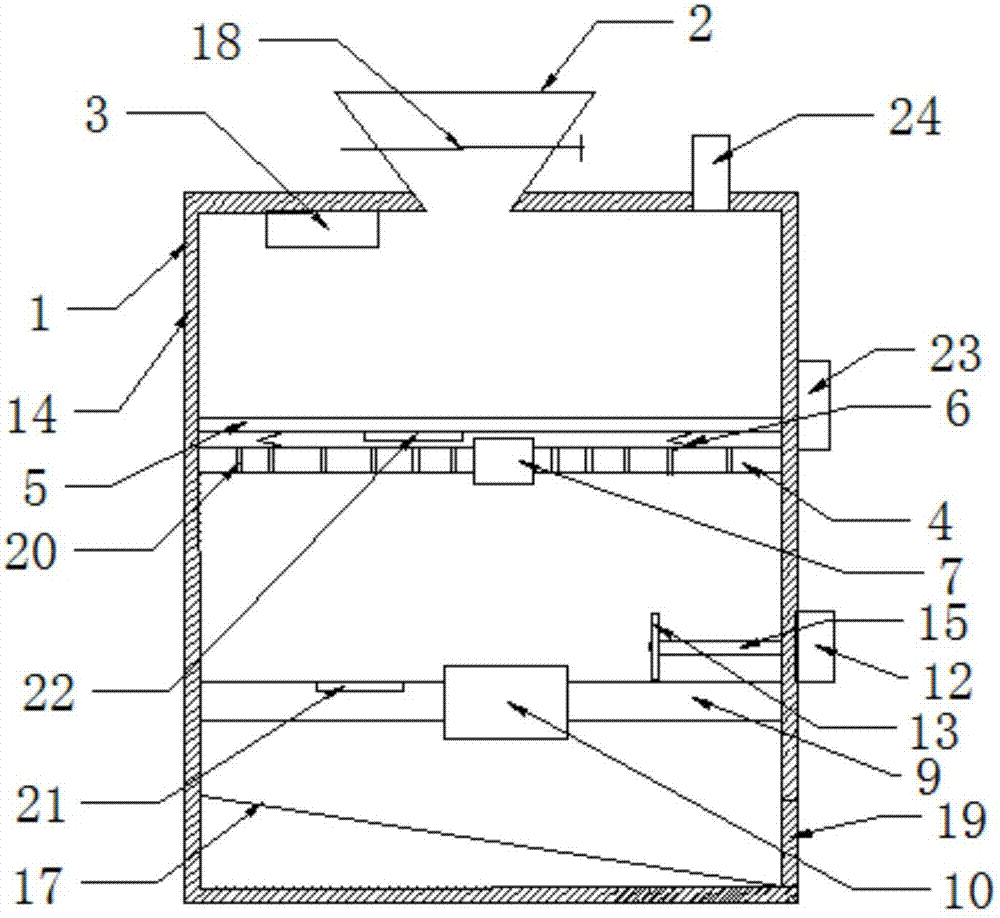

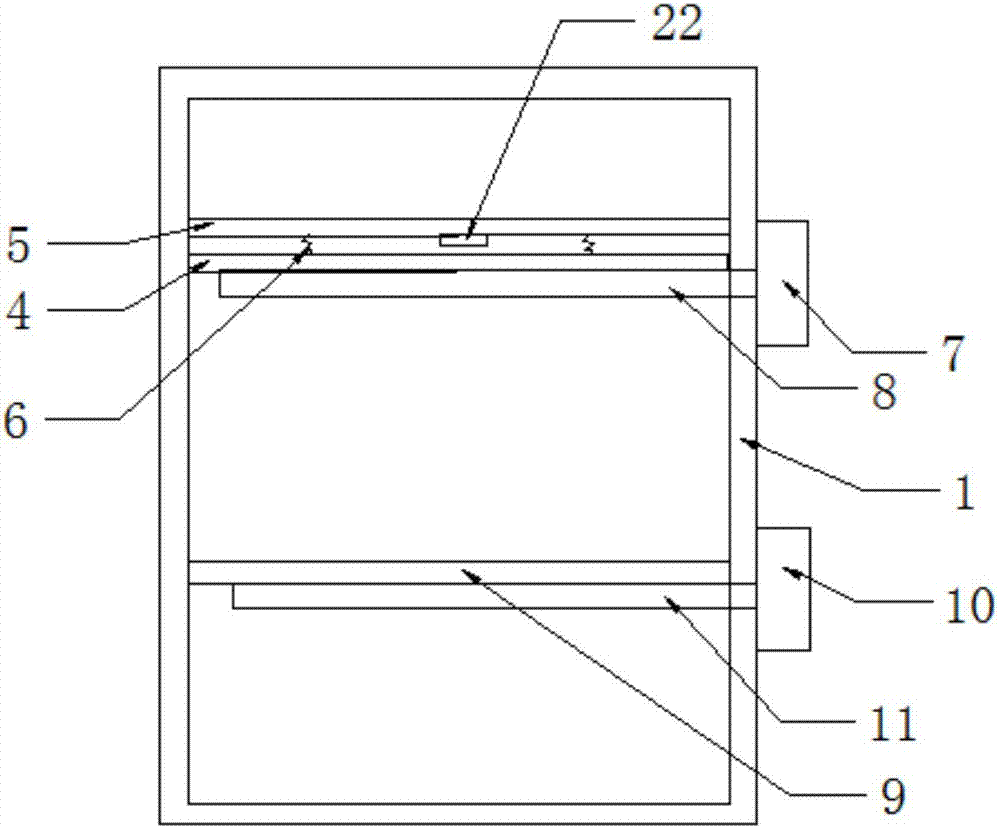

[0029] Such as Figure 1-3 As shown, a reversible powder coating drying equipment includes a box body 1. The box body is in the shape of a cuboid. The top of the box body 1 is provided with a feed hopper 2 and an air outlet 24. There is a discharge port 19;

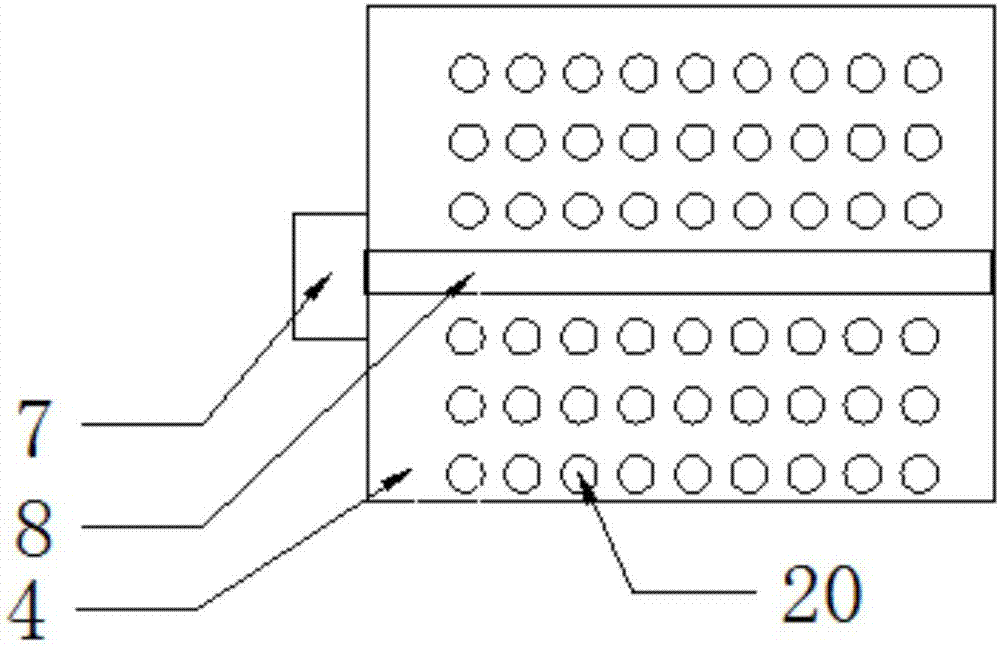

[0030] The box body 1 is provided with a first rotating shaft 8, and the front side wall of the box body 1 is fixedly provided with a first motor 7, and the first motor 7 drives the first rotating shaft 8 to rotate; the upper surface of the first rotating shaft 8 is fixedly provided with A horizontal plate 4, a first storage plate 5 is arranged above the horizontal plate 4, and the horizontal plate 4 and the first storage plate 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com