No-disassembly and no-washing range hood using micronanometer air bubble cleaning technology

A technology of micro-nano bubbles and range hoods, which is applied in the direction of removing oil fumes, cleaning methods and utensils, and cleaning methods using liquids. Achieve the effect of small size, high adsorption rate and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

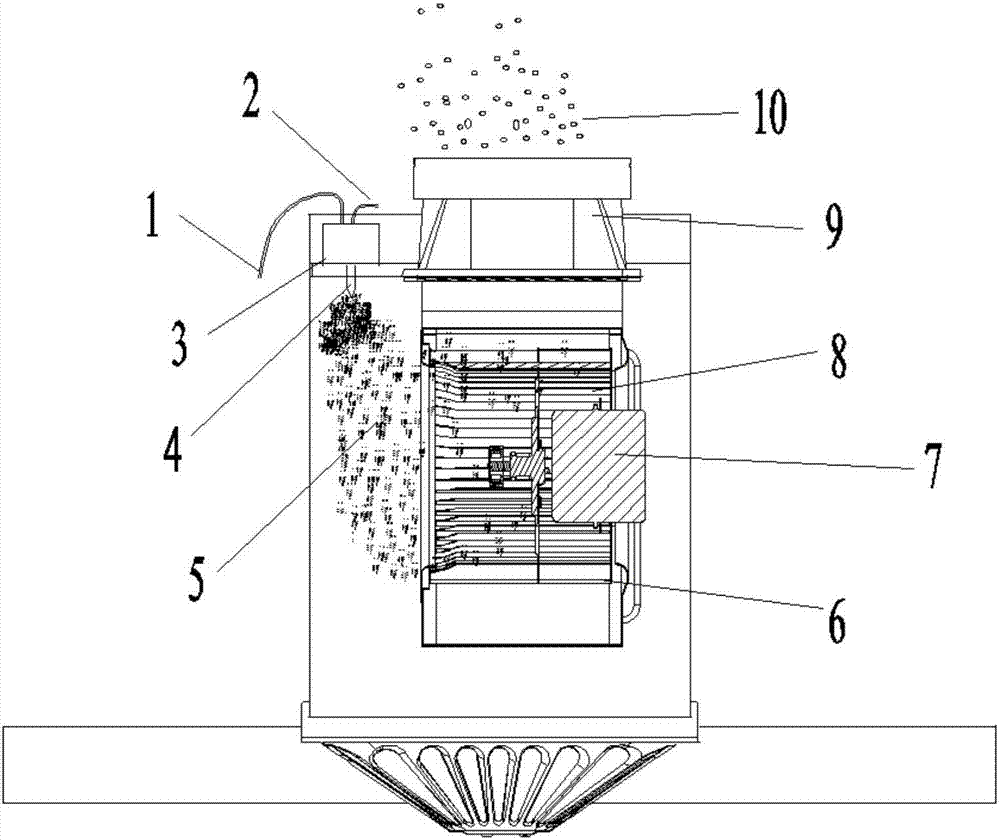

[0025] Embodiment 1: This non-disassembly and cleaning range hood includes a fan volute 6, a motor 7, and an impeller 8. The fan volute 6, motor 7, and impeller 8 are installed in the range hood, and also includes a micro-nano bubble generating device 3 , in the normal working state of the range hood, the micro-nano bubbles 5 generated by the micro-nano bubble generating device 3 are attached to the fan volute 6, the motor 7, and the impeller 8, and the high-speed micro-nano bubbles 5 collide with the surfaces at different positions, collapsing The generated high-pressure jets have a strong impact on the impeller 8 and blades in the volute 6 of the range hood fan, thereby quickly cleaning the oil dirt of the fan system in the range hood. During the cleaning process, the generated micro-nano bubbles are characterized by small size, large specific surface area, and high adsorption rate, which are beneficial to the cleaning of oil dirt. After cleaning, the oil dirt particles 10 ar...

Embodiment 2

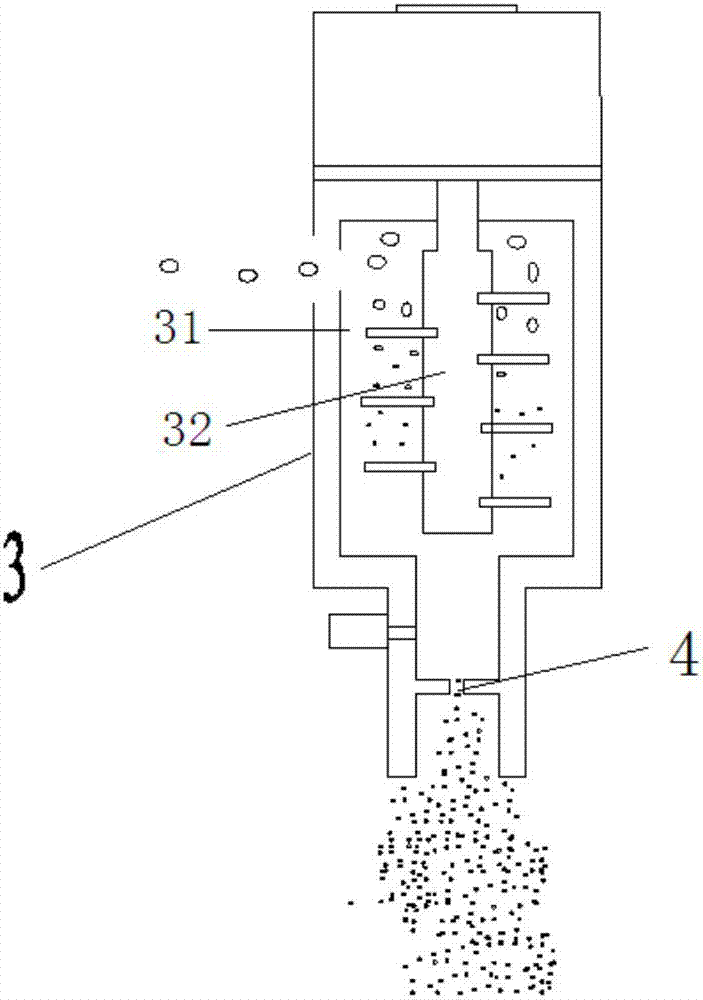

[0026] Embodiment 2: The difference from Embodiment 1 is that the micro-nano bubble generating device 3 is located directly above the range hood, and the outside is connected with a water inlet pipe 1, an air inlet pipe 2 and a micro-nano bubble spout 4, passing through the micro-nano bubble The internal control and adjustment of the generating device 3 generates a large number of high-concentration micro-nano bubbles 5 to be ejected through the micro-nano-bubble nozzle 4 .

Embodiment 3

[0027] Embodiment 3: The difference from Embodiment 2 is that the micro-nano-bubble nozzle 4 is installed at the bottom of the micro-nano-bubble generating device 3, and the installation position is vertically downward, which is conducive to smooth flow to the fan volute 6, The motor 7 and the impeller 8 are cleaned smoothly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com