Sealing waterproof structure of deep groove ball bearing

A deep groove ball bearing and waterproof structure technology, which is applied to bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of easy exposure of lubricating grease, greatly reduced bearing life, increased bearing wear, etc., and increase the axial bearing capacity , improve life, increase the effect of radial bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and drawings are used in conjunction with the detailed description, and the description is as follows:

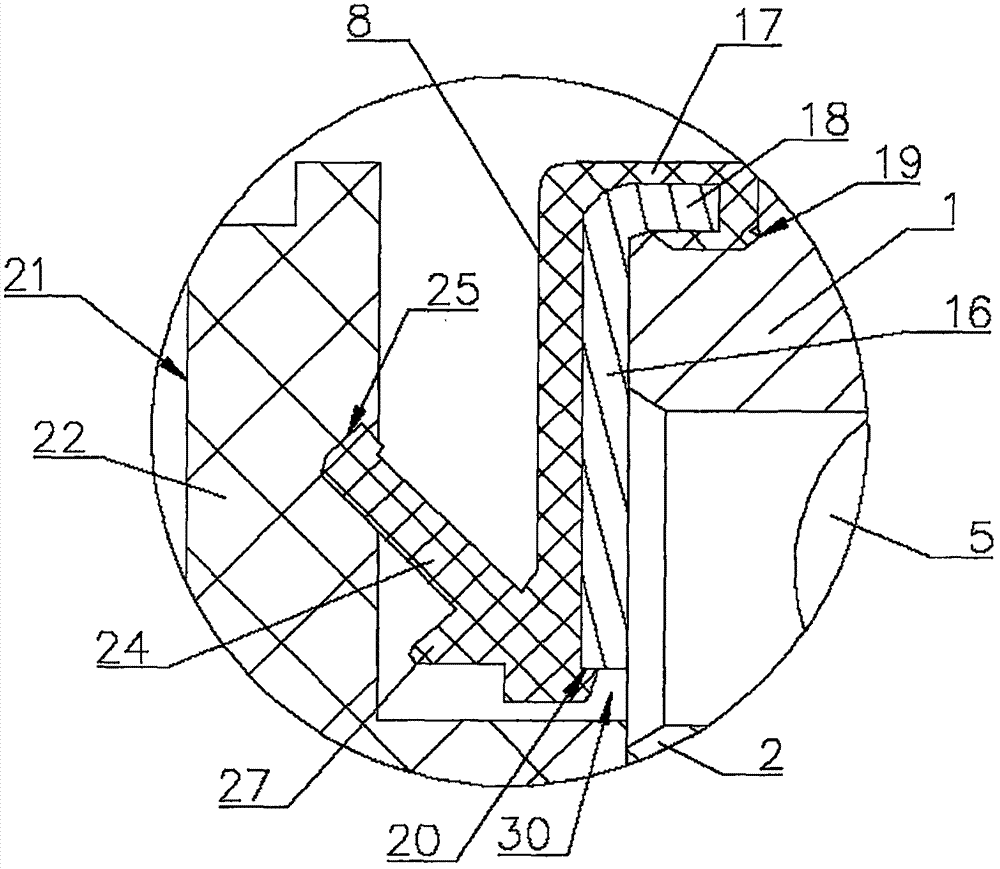

[0023] Such as Figure 1 to Figure 3 As shown, the present invention discloses a deep groove ball bearing sealed and waterproof structure, which includes an inner ring 1, an outer ring 2, a steel ball 5, a cage 6 groups and a sealing device, wherein the inner ring 1 and the outer ring 2 correspond to An inner channel 3 and an outer channel 4 are provided to accommodate the sliding of the steel ball 5; both the inner channel 3 and the outer channel 4 are composed of two circular arcs with a curvature greater than that of the steel ball 5 and symmetrical on both sides. The channel, the contact point of the inner ring 1 and the contact point of the outer ring 2 are all changed from one tangent point of the tradit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com