Gasifiable oxygenated low-carbon high-performance clean gasoline

A high-performance, clean technology, applied in the petroleum industry, liquid carbon-containing fuels, fuels, etc., can solve the problems of reducing the service life of automotive internal combustion engines and related components, not being widely recognized, corroding automotive fuel tanks, etc., to reduce smog weather Formation, reduce pollution, improve the effect of octane number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

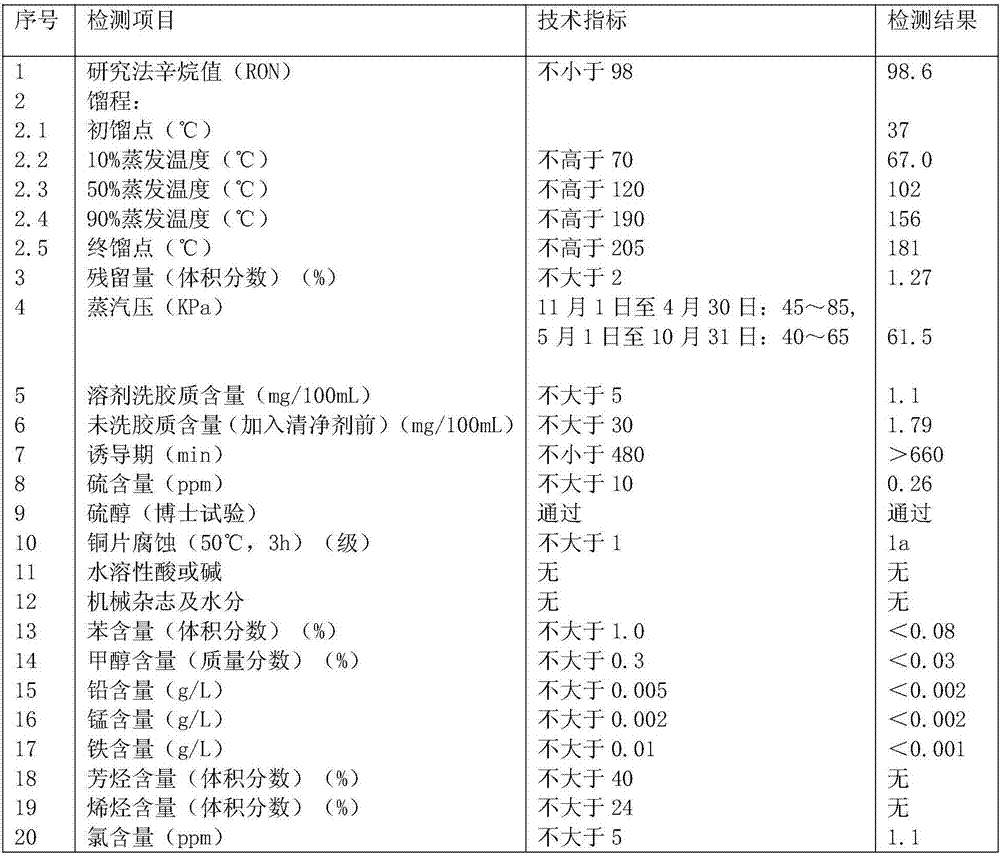

[0022] Embodiment 1: Contain n-butane, isohexane, isooctane, isoamyl alcohol, propylene glycol and n-butanol in the gasoline raw material, and their mass ratio is counted as: 5 parts of normal butane, 15 parts of isohexane, isohexane 30 parts of octane, 18 parts of isoamyl alcohol, 10 parts of propylene glycol, and 22 parts of n-butanol. The gasoline of this example exists in liquid form. Its main technical indicators are tested with reference to the fifth stage emission standard of GB / 17930-2016 motor gasoline No. 98, and the main technical indicators meet the standards. The specific indicators are shown in Table 1.

[0023] Table I

[0024]

Embodiment 2

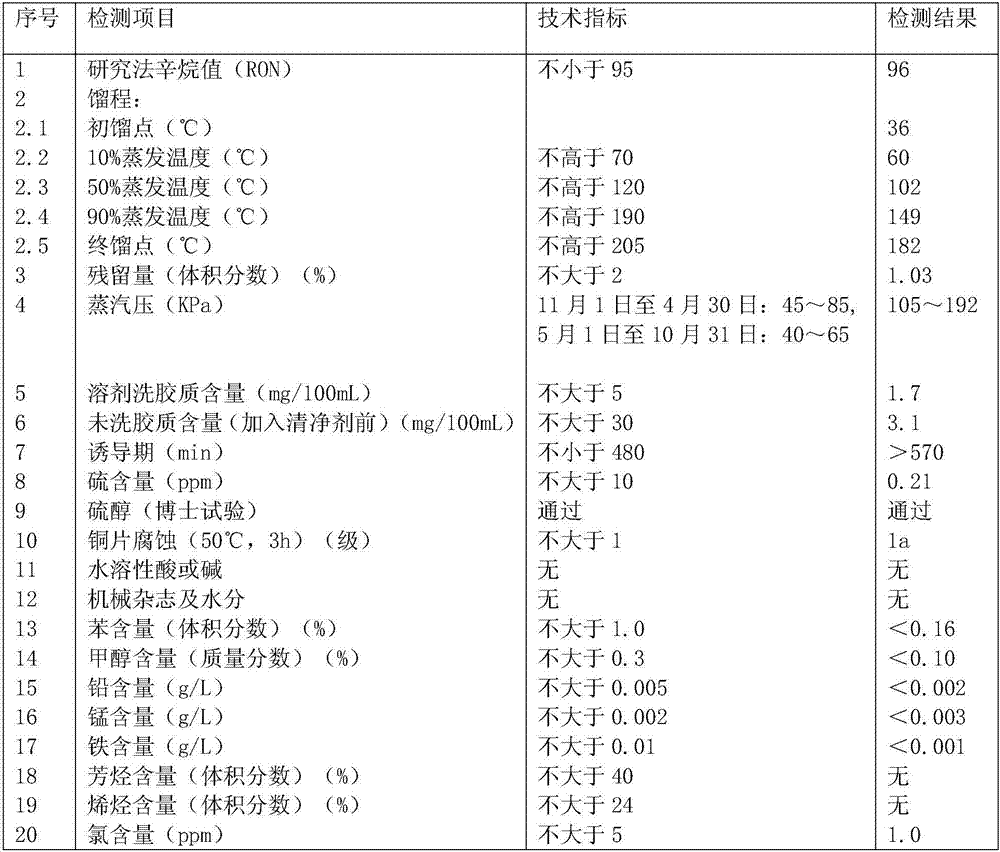

[0025] Embodiment 2: Contain n-butane, isohexane, isooctane, isoamyl alcohol, propylene glycol and n-butanol in the gasoline raw material, and their mass ratio is counted as: 30 parts of normal butane, 10 parts of isohexane, isohexane 10 parts of octane, 10 parts of isoamyl alcohol, 6 parts of propylene glycol, and 14 parts of n-butanol. The gasoline in this embodiment is gaseous, and the main technical indicators are tested with reference to the fifth stage emission standard of GB / 17930-2016 motor gasoline No. 95. The main technical indicators meet the standards, and the specific indicators are shown in Table 2.

[0026] Table II

[0027]

Embodiment 3

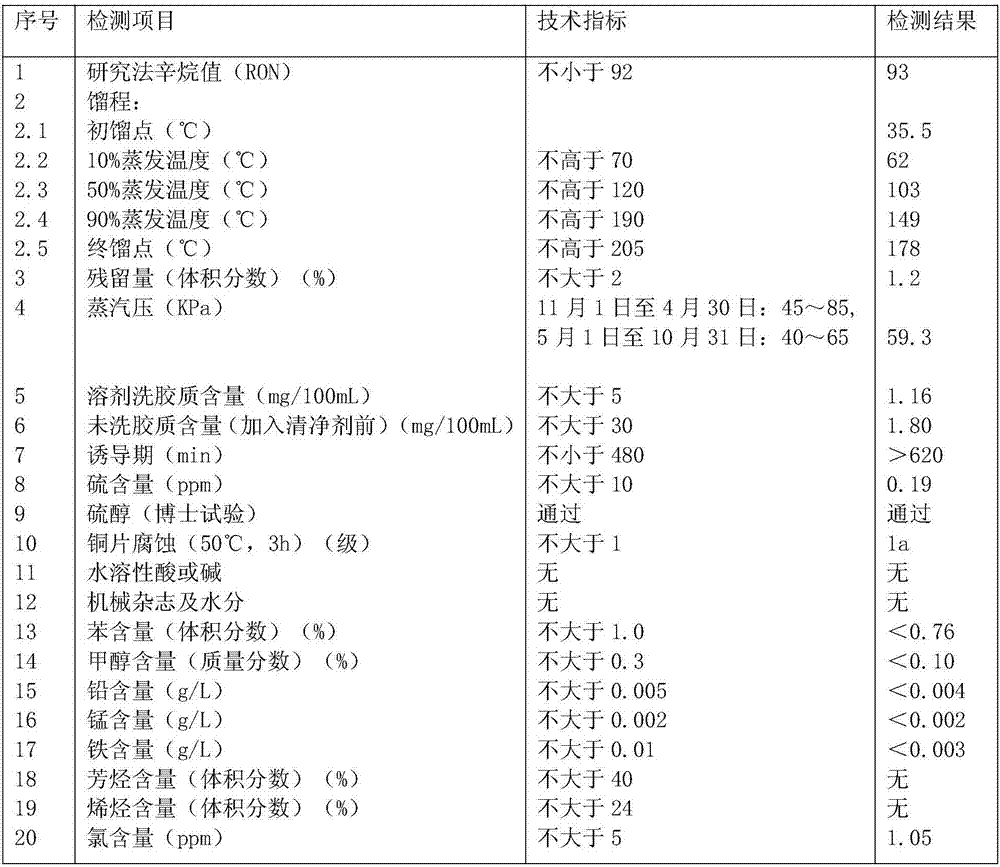

[0028] Embodiment 3: Contain n-butane, isohexane, isooctane, isoamyl alcohol, propylene glycol and isobutanol in the gasoline raw material, and their mass proportions are calculated by parts: 7 parts of normal butane, 15 parts of isohexane, 15 parts of isooctane, 18 parts of isoamyl alcohol, 10 parts of propylene glycol, and 20 parts of isobutanol. The gasoline in this embodiment is in liquid state, and the main technical indicators refer to GB / 17930-2016 Motor Gasoline No. 92 No. 5 Stage Emission Standard for detection, and the main technical indicators meet the standards, and the specific indicators are shown in Table 3.

[0029] Table three

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com