Method for preparing mesophase pitch by utilizing mesotherm coal pitch

A technology of mesophase pitch and coal tar pitch, which is applied in the field of preparation of mesophase pitch, can solve the problems of poor optical structure of mesophase pitch ash content, and achieve the effects of reduced production cost, excellent optical structure and low ash content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

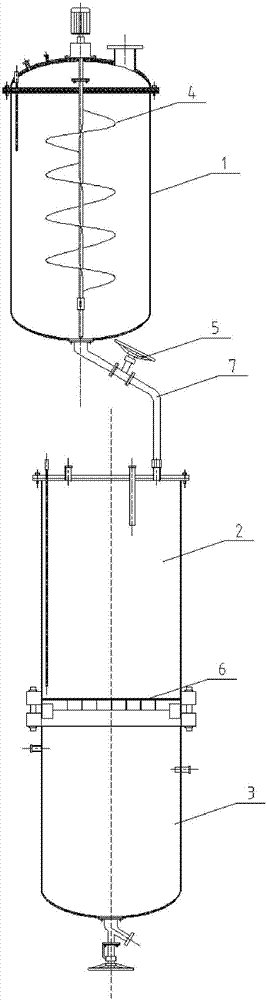

[0020] A device for preparing mesophase pitch from medium-temperature coal tar pitch, which includes a thermal condensation polymerization kettle 1, a thermal filter kettle 2, a material receiving tank 3, an agitator 4, a discharge valve 5 and a filter screen 6, and is characterized in that the thermal condensation polymerization kettle 1 is equipped with There is an agitator 4, and the outlet at the bottom of the thermal condensation polymerization kettle 1 is connected to the inlet of the hot filter kettle 2 through a connecting pipe 7, and the hot filter kettle 2 and the receiving tank 3 are connected by flanges, and there is a filter screen 6 at the bottom of the hot filter kettle 2 , there is a discharge valve 5 on the connecting pipe 7.

[0021] The method for preparing mesophase pitch by the medium temperature coal tar pitch is completed in the following steps:

[0022] a. Preparation of refined medium-temperature coal tar pitch: first, add medium-temperature coal tar p...

Embodiment 2

[0026] The method for preparing mesophase pitch by the medium temperature coal tar pitch is completed in the following steps:

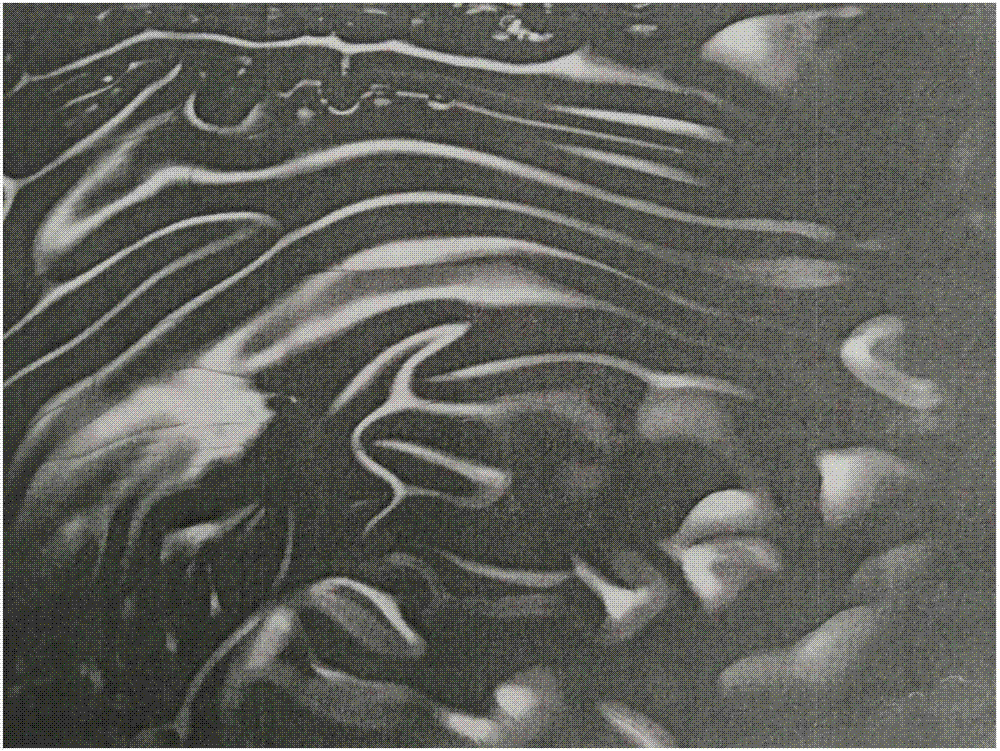

[0027] a. Preparation of refined medium-temperature coal tar pitch: First, add medium-temperature coal tar pitch with a softening point of 80°C into thermal condensation polymerization kettle 1, close the feeding port, and use a vacuum pump to pump out the air in thermal condensation polymerization kettle 1, then fill the kettle with nitrogen (heat filter kettle 2 and the material receiving tank 3 are purged with nitrogen and then protected by nitrogen), after 2 hours, the temperature is raised to 430 °C, and the pressure is 4 MPa, and the stirring speed is 400r / min. The reaction is 2 hours, and the mesophase carbon microspheres or fine mosaic mesophase are generated. Then reduce the pressure in the thermal condensation polymerization kettle 1 to 2MPa, open the discharge valve 5 at the bottom of the thermal condensation polymerization kettle 1, and pre...

Embodiment 3

[0031] The method for preparing mesophase pitch by the medium temperature coal tar pitch is completed in the following steps:

[0032] a. Preparation of refined medium-temperature coal tar pitch: first, add medium-temperature coal tar pitch with a softening point of 90°C into heat condensation polymerization kettle 1, close the feeding port, and use a vacuum pump to pump out the air in heat condensation polymerization kettle 1, then fill the kettle with nitrogen (heat filter kettle 2 and the material receiving tank 3 are purged with nitrogen and then protected by nitrogen), after 2 hours, the temperature is raised to 450°C, and the pressure is 4.2MPa, and the stirring speed is 450r / min. The reaction is 1h, and the mesophase carbon microspheres or fine mosaic mesophase are generated. , and then reduce the pressure in the thermal condensation polymerization kettle 1 to 1.5MPa, open the bottom discharge valve 5 of the thermal condensation polymerization kettle 1, and press the the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com