Low-temperature ceramic silicone rubber and preparation method thereof

A technology of low-temperature ceramics and silicone rubber, which is applied in the field of fire-resistant and flame-retardant silicone rubber. It can solve the problems of low porcelain strength and loose ceramic body structure, and achieve the effect of enhanced thermal conductivity and thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In terms of mass percentage, the distribution ratio of each raw material component of a low-temperature ceramizable silicone rubber is:

[0036] Methyl vinyl silicone rubber 80%

[0037] Fumed silica 5%

[0038] Halloysite 5%

[0039] Glass powder 5%

[0041] Hydroxy silicone oil 1%

[0042] DBPMH1%

[0043]When preparing, first mix boron nitride and glass powder with a softening point of 350°C for 10 minutes, then sinter in a muffle furnace at 350°C for 60 minutes, cool with the furnace, and grind the mixture for 10 minutes with a three-roll mill to prepare a Composite flux with thermal conductivity;

[0044] Then add silicone rubber, fumed silica, hydroxy silicone oil, halloysite, and compound flux into the rubber mixer, and banbury at 50°C for 30 minutes, then add the vulcanizing agent DBPMH, and mix for 3 minutes to obtain a compound Rubber, parked for 12 hours, and re-milled on the rubber mill for 3 minutes;

[0045] Vulcanize the ...

Embodiment 2

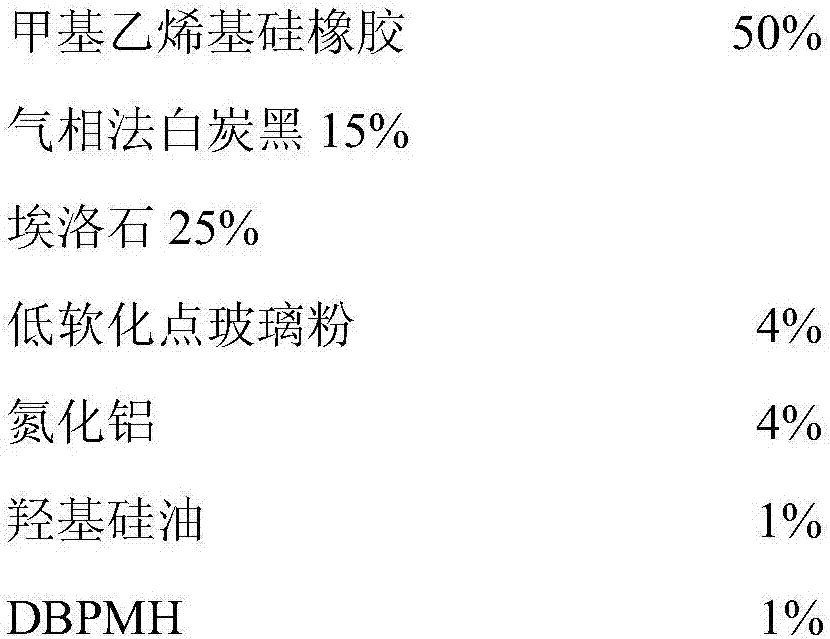

[0048] In terms of mass percentage, the distribution ratio of each raw material component of a low-temperature ceramizable silicone rubber is:

[0049] Methyl vinyl silicone rubber 40%

[0050] Fumed silica 18%

[0051] Halloysite 30%

[0052] Glass powder 5%

[0054] Hydroxy silicone oil 1%

[0055] DBPMH 1%

[0056] Boron nitride and glass powder with a softening point of 650°C were mixed and stirred for 10 minutes, then sintered in a muffle furnace at 650°C for 30 minutes, cooled with the furnace, and the mixture was ground for 20 minutes with a three-roller mill to prepare a thermally conductive Composite flux;

[0057] Add silicone rubber, fumed silica, hydroxy silicone oil, halloysite, and compound flux into the rubber mixer, banbury at 80°C for 5 minutes, then add vulcanizing agent DBPMH, and mix for 3 minutes to obtain a rubber compound , parked for 12 hours, and returned to the rubber mill for 5 minutes;

[0058] Vulcanize the mixed r...

Embodiment 3

[0061] In terms of mass percentage, the distribution ratio of each raw material component of a low-temperature ceramizable silicone rubber is:

[0062] Methyl vinyl silicone rubber 60%

[0063] Fumed silica 10%

[0064] Halloysite 10%

[0065] Low softening point glass powder 10%

[0066] Boron Nitride 8%

[0067] Hydroxy silicone oil 1%

[0068] DBPMH 1%

[0069] First, boron nitride and glass powder with a softening point of 650°C were mixed and stirred for 30 minutes, then sintered in a muffle furnace at 650°C for 30 minutes, cooled with the furnace, and the mixture was ground for 20 minutes with a three-roll mill to prepare a thermally conductive Composite flux;

[0070] Add silicone rubber, fumed silica, hydroxy silicone oil, halloysite, and compound flux into a rubber mixer, banbury at 50°C for 20 minutes, then add vulcanizing agent DBPMH, and mix for 5 minutes to obtain a rubber compound , parked for 12 hours, and returned to the rubber mill for 3 minutes;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com