Composite EVA material for manufacturing slippers and preparation method of composite EVA material

A technology for slippers and raw materials, applied in the application, footwear, clothing and other directions, can solve the problems of poor wear resistance, elastic adhesion, poor compatibility, reduced use performance, and reduced mechanical properties, etc., to achieve good compatibility and reduce decomposition. Temperature and compression set reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

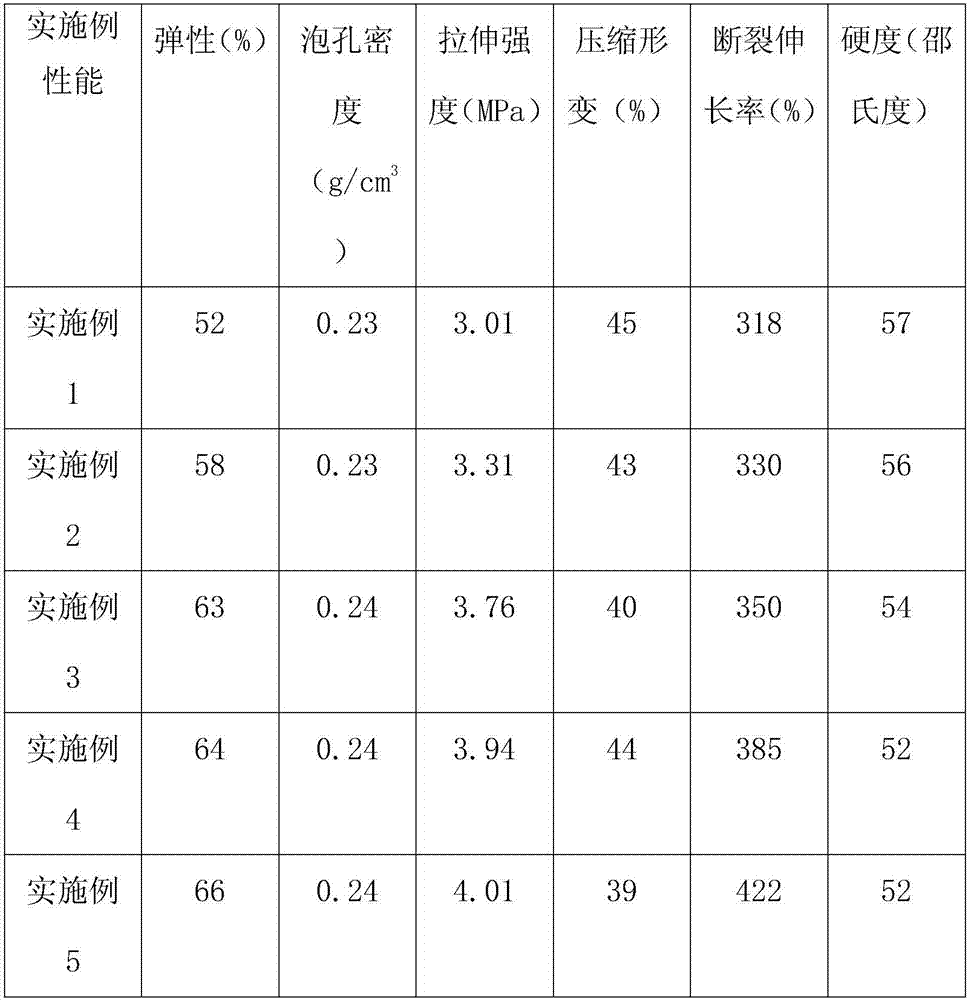

Examples

Embodiment 1

[0019] The present embodiment provides a kind of composite EVA material that is used for slipper manufacture, comprises the raw material of following mass parts: EVA30 parts; Thermoplastic elastomer styrene-isoprene-styrene block copolymer 55 parts; Crosslinking agent 0.75 parts 2.8 parts of blowing agent; 0.8 parts of zinc oxide; 12 parts of POE; 9 parts of maleic anhydride; 5 parts of cell regulator.

[0020] Present embodiment also provides a kind of preparation method of the composite EVA material that is used for slipper manufacture described in above-mentioned scheme, comprises the steps:

[0021] (1) Put EVA, thermoplastic elastomer styrene-isoprene-styrene block copolymer, foaming agent, zinc oxide, POE and maleic anhydride into the open mixer according to the proportion for mixing, Wherein the roller temperature of open mill is 80 ℃, and the roll distance is 0.4mm, and the graft rate of described maleic anhydride is 1%; Then mixed material is extruded into foam master...

Embodiment 2

[0026] The present embodiment provides a kind of composite EVA material that is used for slipper manufacture, comprises the raw material of following mass parts: EVA32 parts; Thermoplastic elastomer styrene-isoprene-styrene block copolymer 56 parts; Crosslinking agent 0.77 2.8 parts of blowing agent; 0.85 parts of zinc oxide; 14 parts of POE; 9.3 parts of maleic anhydride; 5.5 parts of cell regulator.

[0027] Present embodiment also provides a kind of preparation method of the composite EVA material that is used for slipper manufacture described in above-mentioned scheme, comprises the steps:

[0028] (1) Put EVA, thermoplastic elastomer styrene-isoprene-styrene block copolymer, foaming agent, zinc oxide, POE and maleic anhydride into the open mixer according to the proportion for mixing, Wherein the roller temperature of open mill is 85 ℃, and the roll distance is 0.45mm, and the grafting rate of described maleic anhydride is 1.1%; Then mixed material is extruded into foam m...

Embodiment 3

[0033] The present embodiment provides a kind of composite EVA material that is used for slipper manufacture, comprises the raw material of following mass parts: EVA35 parts; Thermoplastic elastomer styrene-isoprene-styrene block copolymer 58 parts; Crosslinking agent 0.8 2.8 parts of blowing agent; 0.9 parts of zinc oxide; 16 parts of POE; 9.5 parts of maleic anhydride; 6 parts of cell regulator.

[0034] Present embodiment also provides a kind of preparation method of the composite EVA material that is used for slipper manufacture described in above-mentioned scheme, comprises the steps:

[0035] (1) Put EVA, thermoplastic elastomer styrene-isoprene-styrene block copolymer, foaming agent, zinc oxide, POE and maleic anhydride into the open mixer according to the proportion for mixing, Wherein the roller temperature of open mill is 90 ℃, and the roll distance is 0.5mm, and the grafting rate of described maleic anhydride is 1.2%; Then mixed material is extruded into foam master...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com