Modified starch for dried-fruit film forming, preparation method therefor and application of modified starch

A technology of modified starch and dried fruit, which is applied in the protection of fruits/vegetables and food science with a protective layer, which can solve the problem that the improvement effect of dried fruit in high temperature and high humidity environment cannot meet the actual needs, and the infestation of dried fruit products by mold. Dyeing, the appearance of dried fruit is not beautiful and other problems, so as to avoid caking or mold growth, weak retrogradation, and transparent and bright paste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

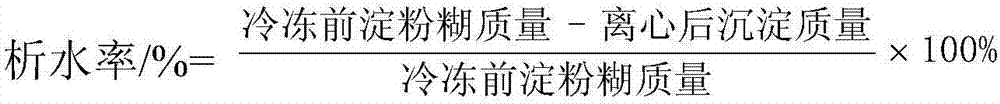

Method used

Image

Examples

Embodiment 1

[0039] The modified starch used for film-hanging of dried fruit in this embodiment is prepared by the following method, and the specific operation steps are:

[0040] 1) Take 100 parts of tapioca starch, add 150 parts of water, stir and disperse for 30 minutes, and obtain the original starch slurry;

[0041] 2) adding a sodium hydroxide solution with a mass concentration of 2.5% to the raw starch slurry prepared in step 1), adjusting the pH of the raw starch slurry to 7.8, and raising the temperature to 32°C;

[0042] 3) Add 3 parts of sodium hypochlorite to the treated raw starch slurry in step 2), raise the temperature to 38° C., maintain pH = 8.0 to 9.5, and after reacting for 3 hours, add 1.5 parts of sodium sulfite to terminate the oxidation reaction to obtain oxidized starch slurry;

[0043] 4) Adjust the pH of the oxidized starch slurry prepared in step 3) to 10 at a temperature of 38° C., add 4 parts of vinyl acetate, react for 3 hours, add hydrochloric acid solution w...

Embodiment 2

[0046] The modified starch used for film-hanging of dried fruit in this embodiment is prepared by the following method, and the specific operation steps are:

[0047] 1) Take 100 parts of potato starch, add 120 parts of water, stir and disperse for 30 minutes, and obtain the original starch slurry;

[0048] 2) adding a sodium hydroxide solution with a mass concentration of 2.0% to the raw starch slurry prepared in step 1), adjusting the pH of the raw starch slurry to 7.5, and raising the temperature to 30° C.;

[0049]3) Under the condition of constant stirring, slowly add 2 parts of sodium hypochlorite to the treated raw starch slurry in step 2), and raise the temperature to 35°C, maintain pH = 8.0-9.5, after reacting for 5 hours, add 1 part of sodium bisulfite , terminate the oxidation reaction to obtain oxidized starch slurry;

[0050] 4) Adjust the pH of the oxidized starch slurry prepared in step 3) to 9.0 at a temperature of 35° C., add 3 parts of vinyl acetate, react f...

Embodiment 3

[0053] The modified starch used for film-hanging of dried fruit in this embodiment is prepared by the following method, and the specific operation steps are:

[0054] 1) Take 100 parts of tapioca starch, add 200 parts of water, stir and disperse for 30 minutes to obtain the original starch slurry;

[0055] 2) adding a sodium hydroxide solution with a mass concentration of 3.0% to the raw starch slurry prepared in step 1), adjusting the pH of the raw starch slurry to 8.0, and raising the temperature to 35°C;

[0056] 3) Add 4 parts of hydrogen peroxide with a mass concentration of 30% to the raw starch slurry treated in step 2), and heat up to 40° C., maintain pH=8.0 to 9.5, and react for 1 hour, then add 2 parts of sodium thiosulfate, Terminate the oxidation reaction to obtain oxidized starch slurry;

[0057] 4) Adjust the pH of the oxidized starch slurry prepared in step 3) to 10.5 at a temperature of 40° C., add 5 parts of vinyl acetate, and react for 2 hours, then add a hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com