AEC electric flocculation waste water treatment system

A wastewater treatment system, electrocoagulation technology, applied in the direction of gaseous effluent wastewater treatment, water/sewage treatment, neutralized water/sewage treatment, etc., can solve the difficulty of high hardness wastewater treatment, poor suspension treatment effect, secondary product Pollution and other issues to achieve the effect of promoting the promotion of environmental protection technology, reliable treatment effect, and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

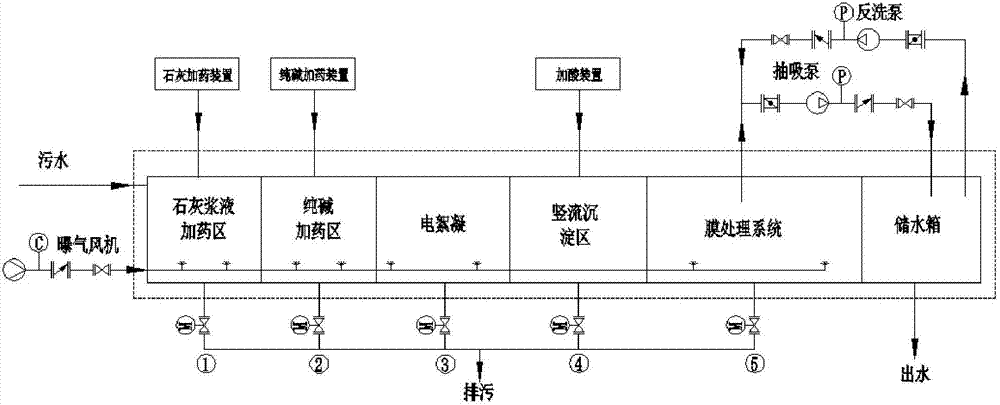

[0043] Such as figure 1 The shown electrocoagulation wastewater treatment system is sequentially connected to the conductive alkaline additive dosing subsystem, electrocoagulation subsystem, sedimentation area, membrane treatment subsystem and water storage tank, and the alkaline additive dosing subsystem is divided into It is a lime slurry dosing area and a soda ash dosing area. Each of the above-mentioned subsystems and sedimentation areas has a wastewater treatment tank (pool), and the wastewater flows through the above-mentioned subsystems and sedimentation areas in turn for treatment.

[0044] Add lime slurry and soda ash to the lime slurry dosing area and soda ash dosing area to neutralize the acidic components in the wastewater and make the pH of the wastewater ≥ 7. At the same time, an aeration pipeline is installed at the bottom of the wastewater treatment tank of the alkaline additive dosing subsystem, electrocoagulation subsystem, and membrane treatment subsystem, a...

Embodiment 2

[0054] Adopt the device system described in embodiment 1 to process desulfurization waste water, will 1m 3 Add lime to the waste water, and carry out sufficient aeration to make the pH value reach 12, remove the carbonate hardness in the water, add soda ash for a full reaction, remove the non-carbonate hardness, and remove the sludge to make the waste water enter the electrocoagulation reaction The reactor reacts for 10 minutes, then enters the vertical flow sedimentation tank, adjusts the pH to 6-9 by adding acid, and finally passes through the membrane treatment system to effluent. The wastewater before and after treatment was inspected, and the detailed test results of various indicators are shown in Table 1.

[0055] Table 1 Wastewater test results

[0056] project

unit

Wastewater before treatment

Treated wastewater

HG

mg / L

0.75

0.04

Total Cadmium

mg / L

0.63

0.08

total chromium

mg / L

0.12

0.1

ars...

Embodiment 3

[0061] The device system described in Example 1 is used to treat the desulfurization wastewater, and a certain company 2m 3 Add 7kg of lime to the coal washing and desulfurization wastewater, and carry out sufficient aeration to make the pH value reach 11. Then, add 15kg of soda ash to fully react. After the reaction is complete, the sludge-removed waste water enters the electroflocculation reactor. In the electroflocculation reactor, an aluminum plate is used as a sacrificial plate, and a direct current of 50A and 10V is applied to react for 12 minutes. The aluminum plate is electrolyzed to generate aluminum ions for the flocculation reaction of the waste water. Then the wastewater enters the vertical flow sedimentation tank, and hydrochloric acid is added to adjust the pH to 8. The impurities after natural precipitation are collected by the sludge collection cone and discharged from the sludge discharge valve at the bottom of the sedimentation area. The wastewater in the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com