A fully mixed mbbr reactor

A reactor and fully mixed technology, applied in the field of reactors, can solve problems such as difficult to adapt to high-concentration organic wastewater, sludge loss, and reactor volume increase, so as to achieve long-term stability of effluent quality, avoid sludge deposition, increase Effect of sludge concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

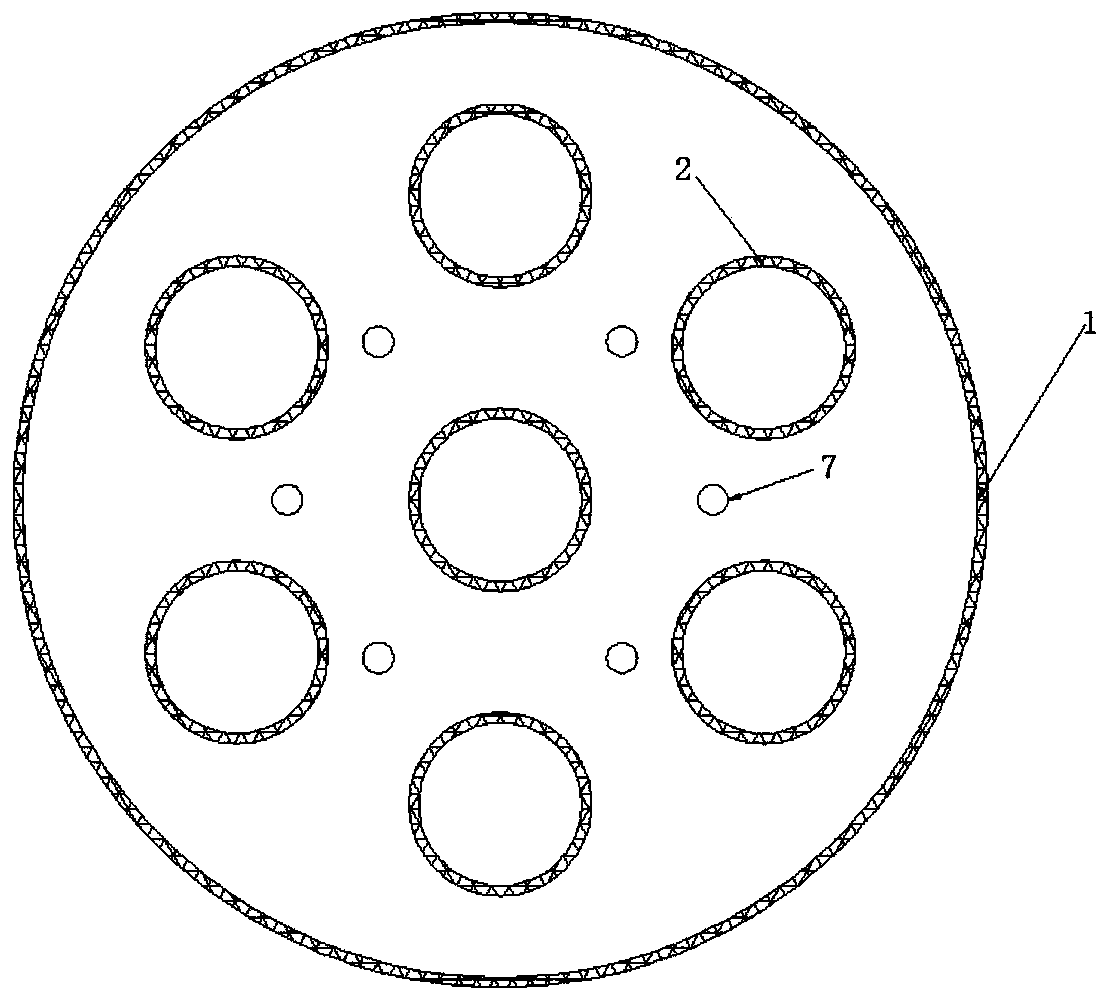

[0025] Such as figure 1 , 2 As shown, the fully mixed MBBR reactor of the present invention includes a cylinder body and a gas-liquid separation tank. The cylinder body is composed of an outer cylinder body and an inner guide tube, wherein the inner guide tube is open at both ends, and the inside is provided with a gas collecting tank. The hood is connected to the air lift tube, and the gas collection hood is connected to the gas-liquid separation tank installed on the upper part of the cylinder through the air lift tube. There is a baffle under the gas collection hood, and the baffle is fixed on the inner wall of the inner guide tube and surrounds along the wall. At the same time, there is a diversion seam between the baffle plate and the air collecting hood for the passage of mud and water. An aeration system is installed in the middle of the height direction of the inner diversion cylinder and connected with the intake pipe of the external fan. The inner diversion cylinder ...

Embodiment 2

[0032] The number of inner guide cylinders described in this embodiment is 5, the effective area ratio of the inner guide cylinder and the outer cylinder is 1:1, and the volume of the gas-liquid separation tank is 1% of the volume of the entire reactor device. The height is 800mm; the width of the sedimentation filter area is 1000mm, and there is a packing layer, the packing layer is bellows packing, the height is 1000mm, and the weir width is 500mm; The width of the diversion seam between the gas hoods is 500mm; the rising flow rate of the mixed liquid in the stripping tube is 2.0m / s; the distance between the mud discharge port and the bottom is 400mm, the size is DN500, and the inside of the cylinder is filled with MBBR filler, the material is poly Ethylene, specific gravity 0.98g / cm 3 , the dosage rate is 20%; the aeration mode of the aeration system is blast aeration. Others are with embodiment 1.

[0033] In the pilot test of a high-concentration organic industrial wast...

Embodiment 3

[0035] The number of inner guide cylinders described in this embodiment is 5, the effective area ratio of the inner guide cylinder and the outer cylinder is 1:1, and the volume of the gas-liquid separation tank is 0.1% of the volume of the entire reactor device. The height is 500mm; the width of the sedimentation filter area is 500mm, and there is a packing layer, the packing layer is bellows packing, the height is 500mm, and the weir width is 200mm; The width of the diversion seam between the gas hoods is 500mm; the rising flow rate of the mixed liquid in the stripping tube is 0.5m / s; the distance between the mud discharge port and the bottom is 400mm, the size is DN500, and the inside of the cylinder is filled with MBBR filler, the material is poly Ethylene, specific gravity 0.98g / cm 3 , the dosage rate is 50%; the aeration mode of the aeration system is blast aeration. Others are with embodiment 2.

[0036] In a pilot test of a high-concentration organic industrial wastew...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com