A kind of ultrasonic-assisted method for preparing vaterite-type calcium carbonate nanoparticles

An ultrasonic-assisted, nanoparticle technology, applied in the fields of calcium carbonate/strontium/barium, nanotechnology, nanotechnology, etc., can solve the problem of difficulty in obtaining ultra-small-sized nano-calcium carbonate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

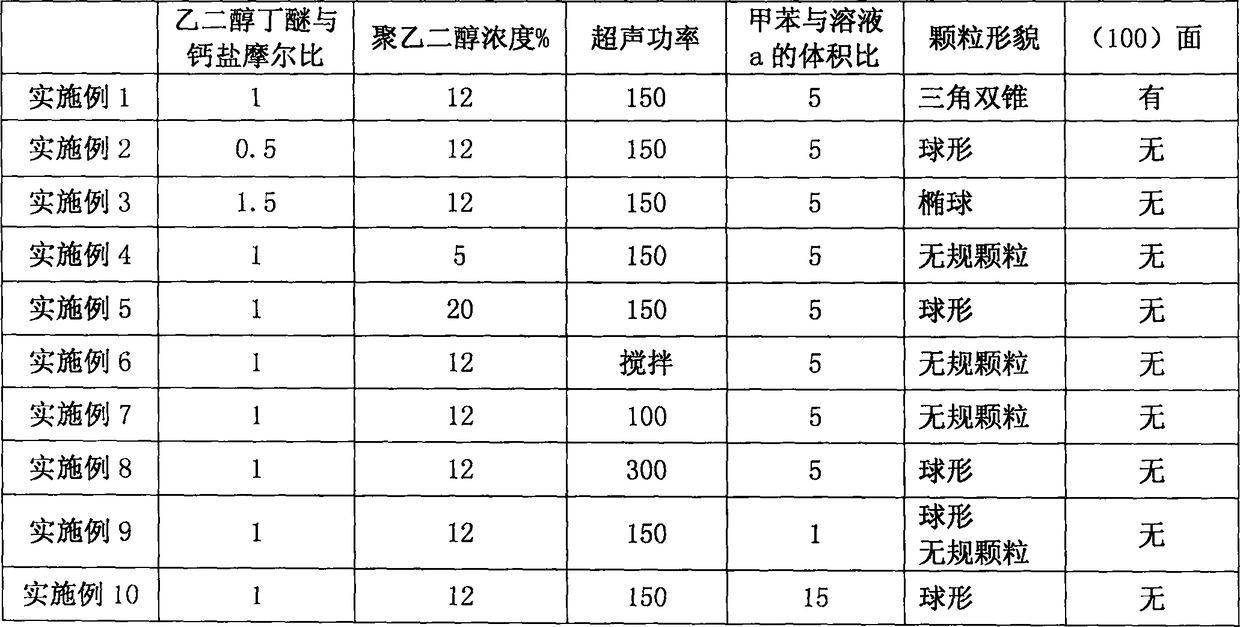

Examples

Embodiment 1

[0022] 1) Prepare solution a: Dissolve calcium nitrate in deionized water so that the concentration of calcium salt is 1mol / L, add ethylene glycol butyl ether, the molar ratio of calcium salt to ethylene glycol butyl ether is 1:1, and stir well ;

[0023] 2) Preparation of solution b: dissolving sodium carbonate in deionized water;

[0024] 3) Dissolve polyethylene glycol in toluene, the mass concentration of polyethylene glycol in toluene is 12%, add solution a, the volume ratio of toluene to solution a is 5:1, stir at 50°C for 1h, cool to room temperature , under ultrasonication, add solution b, ultrasonically react for 15min, ultrasonic power is 150W, and the molar ratio of calcium ion and carbonate ion in the reaction system is 1:1;

[0025] 4) Collect the product, centrifuge, wash, and dry to obtain vaterite-type calcium carbonate triangular conical nanoparticles.

Embodiment 2

[0027] 1) Prepare solution a: Dissolve calcium nitrate in deionized water so that the concentration of calcium salt is 1mol / L, add ethylene glycol butyl ether, the molar ratio of calcium salt to ethylene glycol butyl ether is 1:0.5, and stir evenly ;

[0028] 2) Preparation of solution b: dissolving sodium carbonate in deionized water;

[0029] 3) Dissolve polyethylene glycol in toluene, the mass concentration of polyethylene glycol in toluene is 12%, add solution a, the volume ratio of toluene to solution a is 5:1, stir at 50°C for 1h, cool to room temperature , under ultrasonication, add solution b, ultrasonically react for 15min, ultrasonic power is 150W, and the molar ratio of calcium ion and carbonate ion in the reaction system is 1:1;

[0030] 4) Collect the product, centrifuge, wash, and dry to obtain vaterite-type calcium carbonate triangular conical nanoparticles.

Embodiment 3

[0032] 1) Prepare solution a: Dissolve calcium nitrate in deionized water so that the concentration of calcium salt is 1mol / L, add ethylene glycol butyl ether, the molar ratio of calcium salt to ethylene glycol butyl ether is 1:1.5, and stir evenly ;

[0033] 2) Preparation of solution b: dissolving sodium carbonate in deionized water;

[0034] 3) Dissolve polyethylene glycol in toluene, the mass concentration of polyethylene glycol in toluene is 12%, add solution a, the volume ratio of toluene to solution a is 5:1, stir at 50°C for 1h, cool to room temperature , under ultrasonication, add solution b, ultrasonically react for 15min, ultrasonic power is 150W, and the molar ratio of calcium ion and carbonate ion in the reaction system is 1:1;

[0035] 4) Collect the product, centrifuge, wash, and dry to obtain vaterite-type calcium carbonate triangular conical nanoparticles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com