Non adhesive aluminum honeycomb board

A honeycomb panel and aluminum technology, applied in the field of glue-free aluminum honeycomb panels, can solve the problems of easy degumming of panels, low mechanical properties, unstable structure, etc., and achieve the effects of not easy de-soldering, good protection, and convenient spraying operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

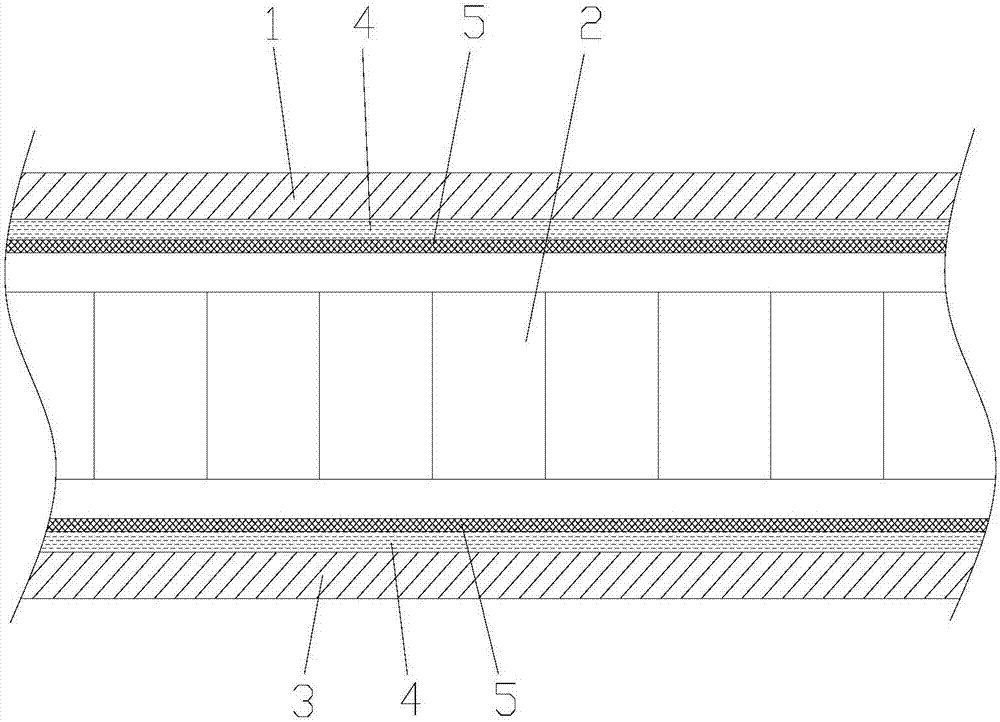

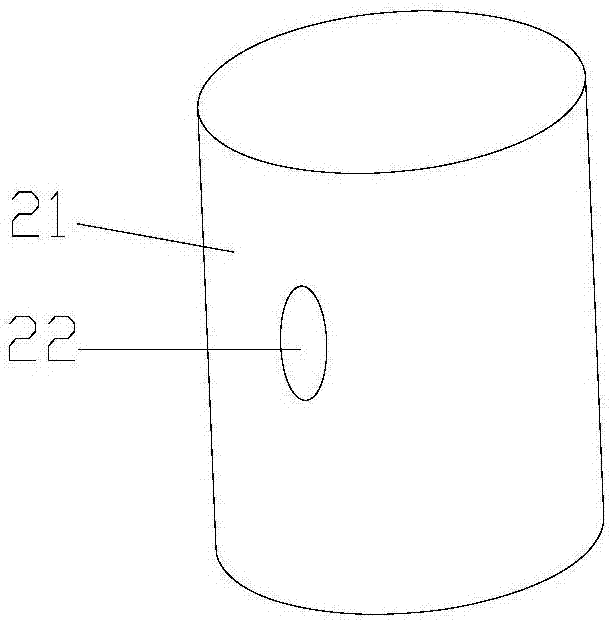

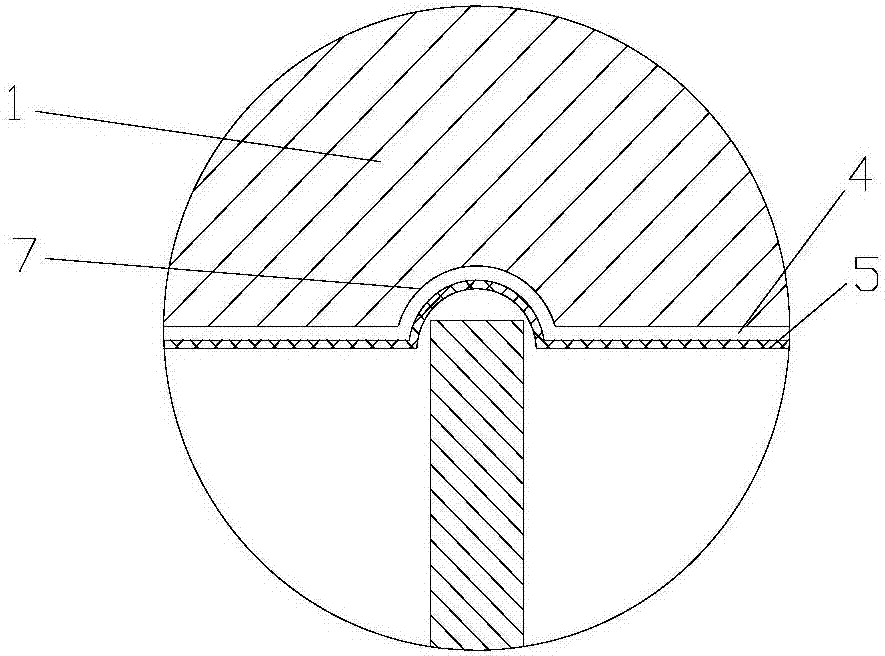

[0026] Embodiment 1: refer to Figure 1 to Figure 5 , Glue-free aluminum honeycomb panel, including aluminum honeycomb core 2, panel 1, bottom plate 3, the honeycomb core 2 is set between the panel 1 and the bottom plate 3, and the panel 1 and the bottom plate 3 are made of 1mm thick and 3003 anti-rust aluminum The inner surface of the panel 1, the bottom plate 3 and the honeycomb core 2 are compounded with a brazing material layer 4 with a thickness of 0.15 mm. The thickness of the brazing material layer of the panel and the bottom plate is 15%. 3003 antirust aluminum has excellent deformation processing and brazing performance, and also has good corrosion resistance. The solder layer is made of 400 type Al-Si eutectic solder. The surface of the solder layer 4 is sprayed with a flux layer 5. The flux layer 5 is composed of Nocolok powder flux and water. Flux aqueous solution, non-corrosive, convenient spraying operation, uniform spraying, spraying before welding, the honeycom...

Embodiment 2

[0027] Embodiment 2: refer to Figure 1 to Figure 7, Glue-free aluminum honeycomb panel, including aluminum honeycomb core 2, panel 1, bottom plate 3, the honeycomb core 2 is set between the panel 1 and the bottom plate 3, the panel 1 and the bottom plate 3 are made of 2mm thick, 3003 anti-rust aluminum , the inner surface of the panel 1, the bottom plate 3 and the honeycomb core 2 are compounded with a 0.14mm thick solder layer 4, and the upper and lower surfaces of the honeycomb core 2 are also compounded with a 0.14mm thick solder layer 4 to strengthen the brazing effect. Rusted aluminum has excellent deformation processing and brazing performance, and also has good corrosion resistance. The brazing filler metal layer is made of 400 type Al-Si eutectic brazing filler metal. The surface of the brazing filler metal layer 4 is sprayed with a flux layer 5, and the flux layer 5 The flux aqueous solution is composed of Nocolok powder flux and water. It is non-corrosive, and the s...

Embodiment 3

[0028] Embodiment 3: refer to Figure 1 to Figure 8 , Glue-free aluminum honeycomb panel, including aluminum honeycomb core 2, panel 1, bottom plate 3, the honeycomb core 2 is set between the panel 1 and the bottom plate 3, and the panel 1 and the bottom plate 3 are made of 1mm thick and 3003 anti-rust aluminum The inner surface of the panel 1, the bottom plate 3 and the honeycomb core 2 are compounded with a brazing material layer 4 with a thickness of 0.15 mm. The thickness of the brazing material layer of the panel and the bottom plate is 15%. 3003 antirust aluminum has excellent deformation processing and brazing performance, and also has good corrosion resistance. The solder layer is made of 400 type Al-Si eutectic solder. The surface of the solder layer 4 is sprayed with a flux layer 5. The flux layer 5 is composed of Nocolok powder flux and water. Flux aqueous solution, non-corrosive, convenient spraying operation, uniform spraying, spraying before welding, the honeycom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com