Concrete power transmission and transformation power line pole with improved anchor plate and production method thereof

A technology for power lines and production methods, which is applied to manufacturing tools, building components, ceramic molding machines, etc., can solve the problems of poor sealing of anchor plates, easy bumping of the end face of the root of the pole, and running of the end face of the root of the pole, etc. The effect of reducing the probability of bumping the end face of the small root, reducing the defect of slurry running, and reducing the probability of the end face being knocked off

Active Publication Date: 2020-04-17

GUANGXI POWER LINE EQUIP FACTORY

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] The prestressed poles of power transmission and transformation lines that we usually see are generally cylinders with one big end and a small end. After being installed on site, the small head is upward, the top is called slightly, and the bottom with a big head is called the root. The root is equipped with an anchor plate. It is further divided into flat end anchor plates and boss end anchor plates. Ordinary poles use flat end anchor plates, and prestressed poles use boss end anchor plates. The currently used flat end anchor plates and boss end anchor plates are the largest The disadvantage is that the tightness of the anchor plate is poor. When the concrete is poured and centrifuged, the end face of the root of the pole is prone to run out defects, and the end face of the root of the pole is easy to be damaged during hoisting or transportation; the installed concrete Power poles are also ugly, so concrete power line pole manufacturers do not want this situation

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0030] The manufacturing method is the same as that of Example 1, and the root anchor plate 13 is 12CrNi3A.

Embodiment 3

[0032] The manufacturing method is the same as that of Example 1, and the root anchor plate 13 is 12CrNi3A.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

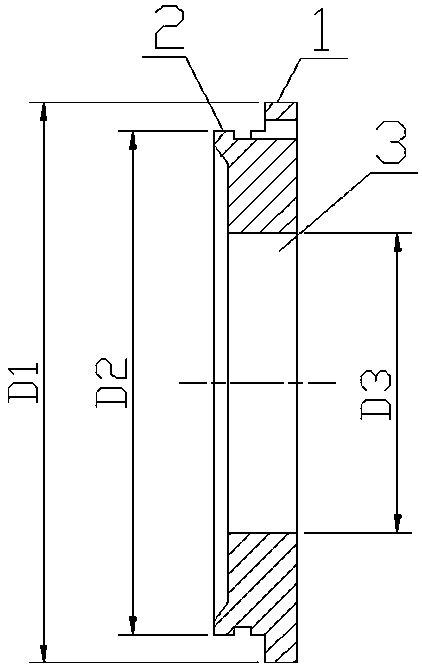

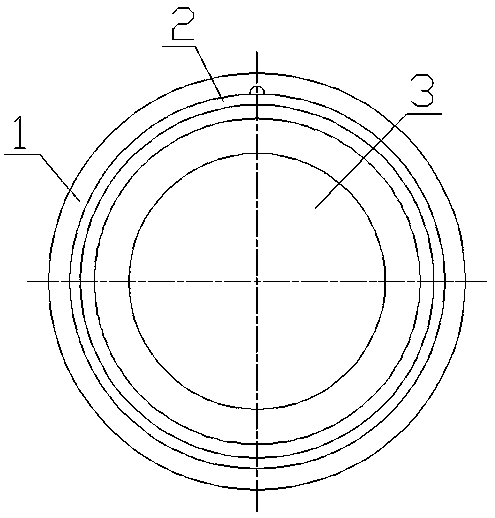

The invention relates to a concrete electric power circuit rod manufacturing method, in particular to an improved anchor plate concrete transmission and transformation electric power circuit electric rod and a production method thereof. The production method includes the steps that an electric rod cage-shaped framework is manufactured, a steel wire is automatically wound, an anchor plate at the root of the electric rod is manufactured, the electric rod cage-shaped framework is subject to concrete grouting and centrifugation, the electric rod is maintained, in the anchor plate improvement process, anchor plate at the root of the electric rod is manufactured firstly, a disc-shaped metal plate is cut, and the external diameter of the disc-shaped metal plate is phi D1 and is the same as the diameter of the electric rod; a boss is turned on the disc-shaped metal plate, the diameter of the boss is phi D2, and the boss is the smoothing end face of the anchor plate and is used for preventing cement slurry from running out from gaps of the anchor plate and an electric rod steel mold wall during electric rod centrifugation; and the phenomenon of end face slurry running defects at the root of the electric rod is reduced.

Description

technical field [0001] The invention relates to the technical field of production of electric power line products for power transmission and transformation, in particular to an anchor plate at the root of a concrete pole with a rounded end face of a boss. Background technique [0002] The prestressed poles of power transmission and transformation lines that we usually see are generally cylinders with one big end and a small end. After being installed on site, the small head is upward, the top is called slightly, and the bottom with a big head is called the root. The root is equipped with an anchor plate. It is further divided into flat end anchor plates and boss end anchor plates. Ordinary poles use flat end anchor plates, and prestressed poles use boss end anchor plates. The currently used flat end anchor plates and boss end anchor plates are the largest The disadvantage is that the tightness of the anchor plate is poor. When the concrete is poured and centrifuged, the end ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B28B23/04B28B23/14B28B23/10E04H12/16E04C5/12

CPCB28B23/043B28B23/10B28B23/14E04C5/12E04H12/16

Inventor 林贤杰覃枫黄家德杨周潘宏林文锋农天高

Owner GUANGXI POWER LINE EQUIP FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com