Multifunctional sofa production technology

A production process and multi-functional technology, applied in the field of furniture, can solve problems affecting production efficiency and product quality, reduce work efficiency, increase labor intensity, etc., achieve good anti-mold and anti-corrosion effects, improve production methods, and improve product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

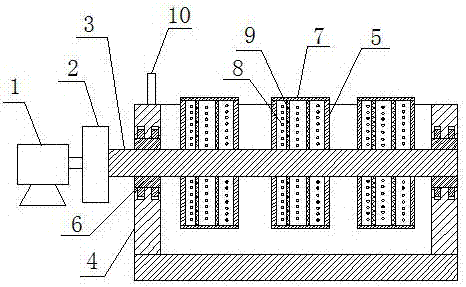

Image

Examples

Embodiment 1

[0019] A multi-functional sofa production process, the specific steps are as follows: (1) ingredients: select the appropriate wood, and use a cutting saw to cut into the required shape of the board; (2) anti-corrosion and anti-mildew treatment: the step (1) The surface of the board is polished, and the burrs and sharp angles on the surface of the board are removed, and then soaked in a soaking device with an anti-mold liquid for 20 minutes at normal temperature and pressure, and then the wood treated with the anti-mold liquid is stacked in an open manner. dry; the anti-mildew solution comprises the following components by weight: 3 parts of calcium chloride, 8 parts of sodium stearate, 10 parts of sodium metaborate, 4 parts of polyethylene glycol, 2 parts of silicon dioxide particles, 10 parts of acetic acid, 2 parts of dibutyltin dilaurate, 1 part of lignin, 2 parts of copper oxide, 2 parts of magnesium oxide, 6 parts of inulin, 8 parts of pyrethrum, and 4 parts of water. Pour...

Embodiment 2

[0022]A multi-functional sofa production process, the specific steps are as follows: (1) ingredients: select the appropriate wood, and use a cutting saw to cut into the required shape of the board; (2) anti-corrosion and anti-mildew treatment: the step (1) The surface of the board is polished, and the burrs and sharp angles on the surface of the board are removed, and then soaked in a soaking device with an anti-mold liquid for 30 minutes at normal temperature and pressure, and then the wood treated with the anti-mold liquid is stacked openly. dry; the anti-mildew solution comprises the following components by weight: 4 parts of calcium chloride, 10 parts of sodium stearate, 12 parts of sodium metaborate, 6 parts of polyethylene glycol, 4 parts of silicon dioxide particles, 12 parts of acetic acid, two 3 parts of dibutyltin laurate, 2 parts of lignin, 4 parts of copper oxide, 4 parts of magnesium oxide, 8 parts of inulin, 10 parts of pyrethrum, and 6 parts of water. Pour the ab...

Embodiment 3

[0024] A multi-functional sofa production process, the specific steps are as follows: (1) ingredients: select the appropriate wood, and use a cutting saw to cut into the required shape of the board; (2) anti-corrosion and anti-mildew treatment: the step (1) The surface of the board is polished, and the burrs and sharp angles on the surface of the board are removed, and then soaked in a soaking device with an anti-mold solution for 28 minutes at normal temperature and pressure, and then the wood treated with the anti-mold solution is stacked in an open manner. dry; the anti-mildew liquid comprises the following components by weight: 3.5 parts of calcium chloride, 9 parts of sodium stearate, 11 parts of sodium metaborate, 5 parts of polyethylene glycol, 3 parts of silicon dioxide particles, 11 parts of acetic acid, 2.5 parts of dibutyltin dilaurate, 1.5 parts of lignin, 3 parts of copper oxide, 3 parts of magnesium oxide, 7 parts of inulin, 9 parts of pyrethrum, and 5 parts of wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com