Automatic bolt pre-tightening method for narrow-opening deep-cavity environment

A deep cavity, automatic technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as high cost, difficult implementation, and inability to achieve visualization, improve assembly accuracy and automation, and solve automatic preloading. , The effect of efficient and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings and technical solutions.

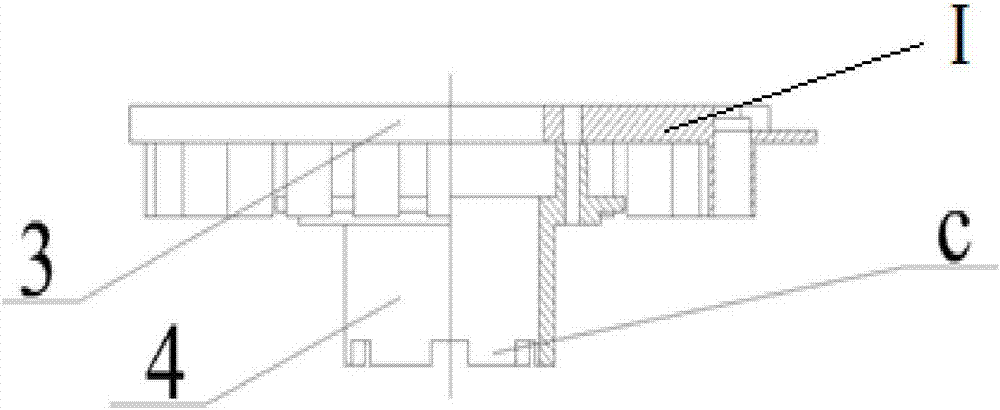

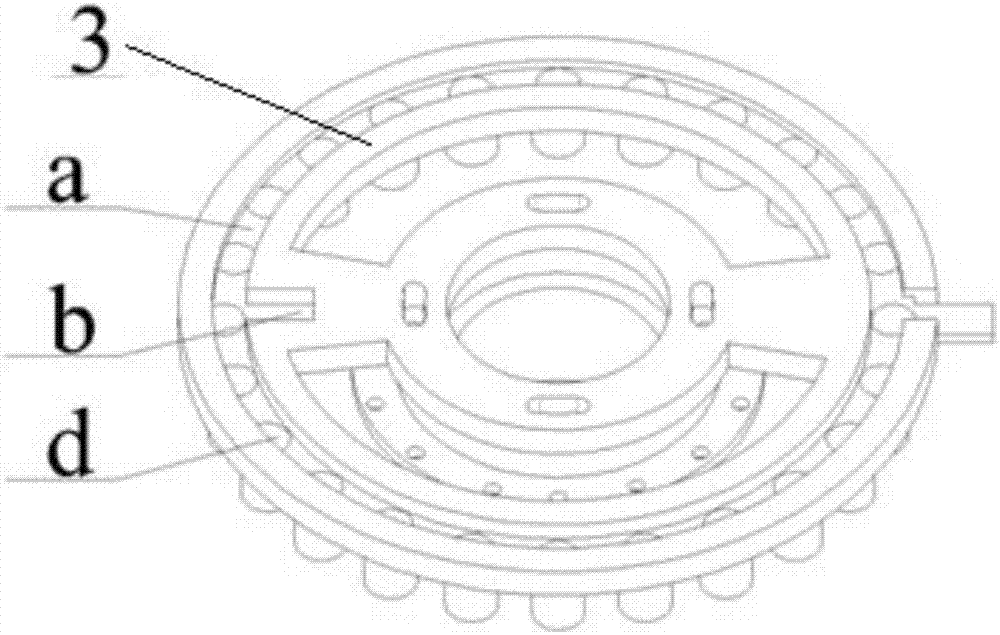

[0021] figure 1 Schematic diagram of the overall structure of the bolt pre-tensioning device installed for the narrow mouth and deep cavity environment, figure 2 is the structural schematic diagram of positioning component I, image 3 Yes figure 2 top view, see figure 1 , 2 3. The positioning component I is assembled at the mouth of the Ф100mm deep cavity through the stop step c on the stop device 4, and mainly plays the role of stop of the cavity, support and fixation of the device and precise positioning. There is a circle of I-shaped chute a on the upper surface of the positioning plate 3. After loading and unloading a nut, the base 5 can be rotated to complete the positioning of other nuts to be loaded and unloaded. The I-shaped chute a has 24 positioning holes at radial intervals. d, the position corresponds to the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com