Dioxin control method in iron ore sintering co-processing garbage fly ash process

A technology of waste fly ash and co-processing, applied in chemical instruments and methods, improvement of process efficiency, removal of solid waste, etc., can solve problems such as environmental pollution, reduce excitation points, reduce the probability of dioxin generation, prevent Effects of harmful gases escaping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

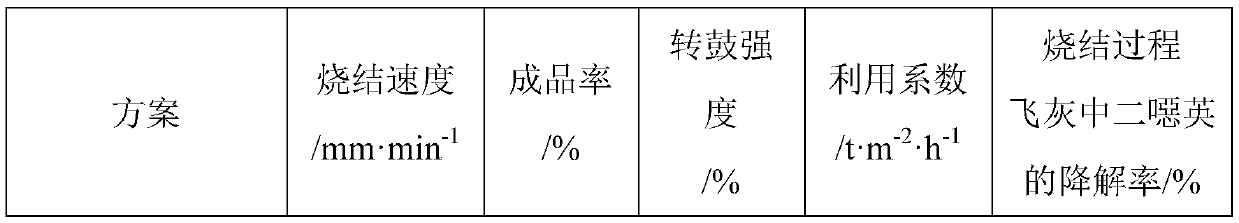

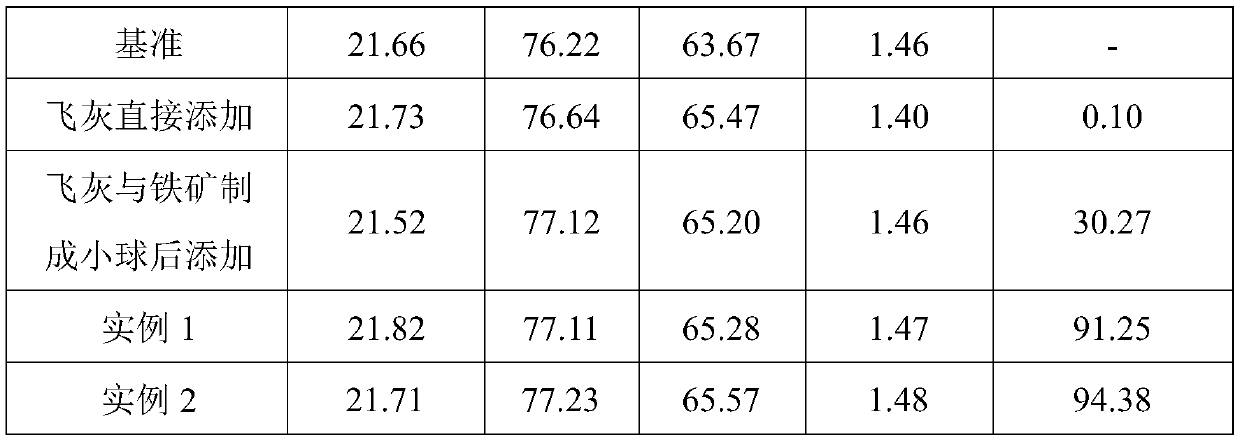

[0032] Mix the garbage fly ash with 5% milk of lime, 15% biochar and 2% municipal sludge (moisture content is about 30%) to make pellets with a particle size of 4mm, and Dry at 80°C for 60 minutes (dry until the water content is less than 5%); then mix the conventional sintering raw materials and then granulate, and add them evenly along the horizontal axis of the cylinder granulator at the last 1 minute after the sintering raw materials are granulated, so that the fly ash is small The balls and sintering raw materials are mixed evenly, the amount of fly ash pellets is 2% of the mass of sintering raw materials, and the obtained mixture is ignited and sintered after being distributed. , the sintering index and the dioxin content in the flue gas are shown in Table 1. It can be seen that the sintering index equivalent to the benchmark can be obtained after the waste fly ash is granulated and dried, and the dioxin content in the fly ash is 91.25%. %. It can be seen that compared ...

Embodiment 2

[0034] Garbage fly ash was evenly mixed with milk of lime accounting for 10% of the mass of fly ash, 6% of biochar and 5% of municipal sludge (moisture content about 35%), and made into pellets with a particle size of 6mm. Dry at ℃ for 20 minutes (dry until the moisture content is less than 5%); then mix the conventional sintering raw materials and then granulate, and add them evenly along the horizontal axis of the cylinder granulator at the last 1 minute after the sintering raw materials are granulated, so that the fly ash pellets Mix evenly with the sintering raw materials, the amount of fly ash pellets is 1% of the mass of the sintering raw materials, and the obtained mixture is ignited and sintered after being distributed. The sintering index and the dioxin content in the flue gas are shown in Table 1. It can be seen that the sintering index equivalent to the benchmark can be obtained by adding the garbage fly ash to sintering after granulation and drying, and the degradat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com