Catalyst recovery process

A catalyst and process technology, applied in the field of catalyst recovery process, can solve the problems of high energy consumption, complex catalyst recovery process, low catalyst recovery rate, etc., and achieve the effects of simplifying the process flow, saving water consumption and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

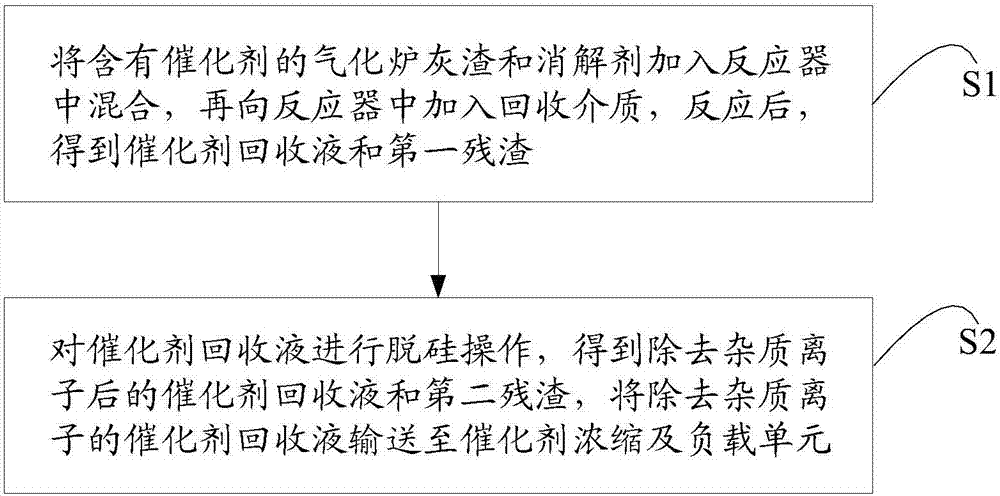

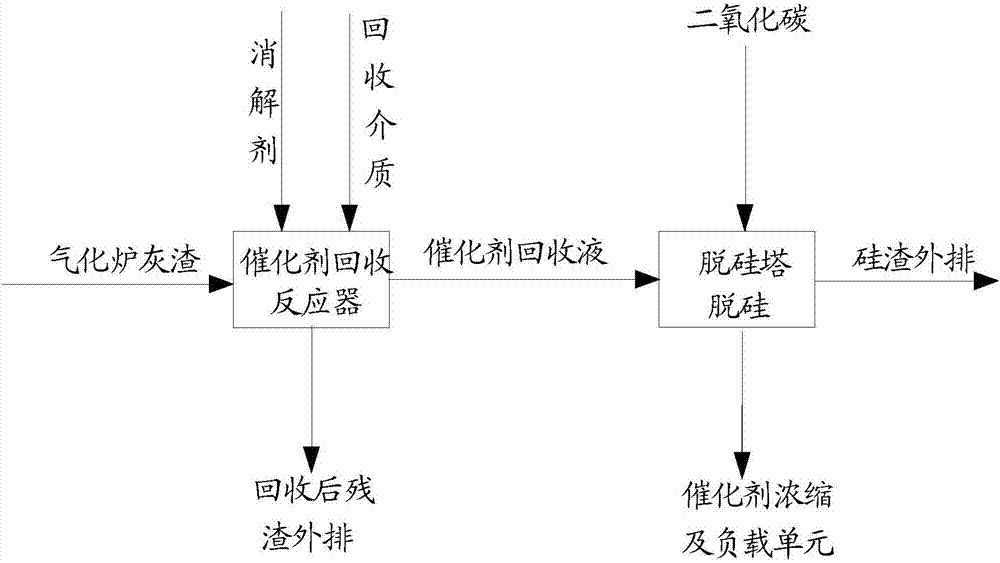

Method used

Image

Examples

Embodiment 1

[0044] At a temperature of 180°C and a pressure of 0.2MPa, take 1Kg of gasifier ash and 0.3Kg of Ca(OH) 2 Put it into the reactor and mix evenly, then add 4Kg of deionized water to the reactor, react for 2h under stirring, and recover the water-soluble catalyst and the water-insoluble catalyst at the same time. After the recovery reaction is completed, after the reaction residue is separated from the catalyst recovery liquid, the catalyst recovery liquid is transported to the desiliconization tower and heated to 30°C. After the recovery liquid is desiliconized by the desiliconization tower, the residue liquid is filtered and separated Recovery liquid and silicon slag. The recovered liquid directly enters the concentration unit for concentration, and the concentrated catalyst solution is sent to the supporting unit for catalyst loading. The catalyst recovery rate and the concentration of impurity ions in the catalyst solution after desiliconization were measured, and the results...

Embodiment 2

[0046] At a temperature of 280℃ and a pressure of 0.3MPa, take 0.5Kg of gasifier ash and 0.02Kg of Ca(OH) 2 Put it into the reactor and mix evenly, then add 3Kg of tap water to the reactor, react for 0.5h under stirring, and at the same time recover the water-soluble catalyst and the non-water-soluble catalyst. After the recovery reaction is completed, after the reaction residue is separated from the catalyst recovery liquid, the catalyst recovery liquid is transported to the desiliconization tower and heated to 40°C. After the recovery liquid is desiliconized by the desiliconization tower, the residue liquid is filtered and separated Recovery liquid and silicon slag. The recovered liquid directly enters the concentration unit for concentration, and the concentrated catalyst solution is sent to the supporting unit for catalyst loading. The catalyst recovery rate and the concentration of impurity ions in the catalyst solution after desiliconization were measured, and the results...

Embodiment 3

[0048] At a temperature of 120°C and a pressure of 4MPa, take 1Kg of gasifier ash and 0.5Kg CaO into the reactor and mix them evenly, then add 2Kg of wastewater from the washing tower to the reactor, and react under stirring 5h, recover both water-soluble catalyst and non-water-soluble catalyst at the same time. After the recovery reaction is completed, after the reaction residue is separated from the catalyst recovery liquid, the catalyst recovery liquid is transported to the desiliconization tower and heated to 50°C. After the recovery liquid is desiliconized by the desiliconization tower, the residue liquid is filtered and separated Recovery liquid and silicon slag. The recovered liquid directly enters the concentration unit for concentration, and the concentrated catalyst solution is sent to the supporting unit for catalyst loading. The catalyst recovery rate and the concentration of impurity ions in the catalyst solution after desiliconization were measured, and the resul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com