Method and system for circularly regenerating diatomite filter aid containing oil waste

A waste diatomaceous earth recycling technology, applied in the direction of filter regeneration, separation methods, chemical instruments and methods, etc., can solve the problems of affecting filtration efficiency, harm, poor quality, etc., and achieve the effect of good shaft sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative work shall fall within the protection scope of the present invention.

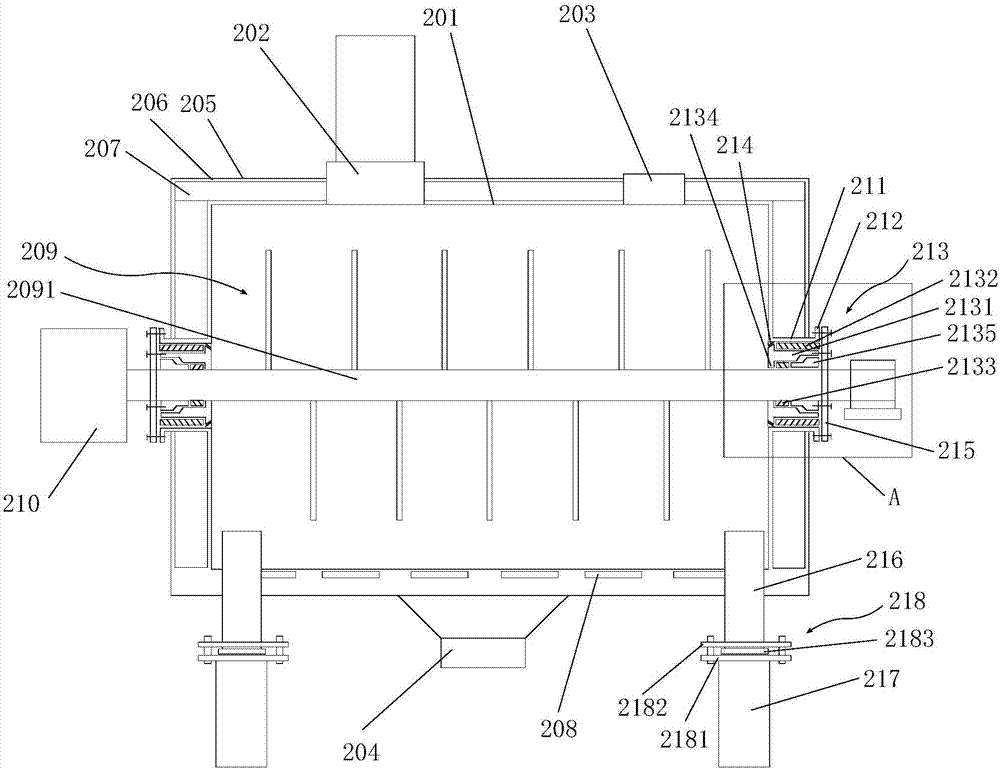

[0050] Such as Figure 1~Figure 10 As shown, the method for recycling oily waste diatomite filter aid proposed in the present invention includes the following steps:

[0051] A. Desorption and regeneration:

[0052] The oily waste diatomaceous earth is sent to the regenerator 2, and the temperature is raised while stirring. It is desorbed and regenerated for 1 to 5 hours at a temperature of 50℃~220℃ and a vacuum degree of -0.01MPa~-0.1MPa to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com