Modified glass for thin-film solar cells, and preparation method of modified glass

A solar cell and modification technology, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of single component and insufficient light transmittance, and achieve the effects of high light transmittance, light weight and improved physical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

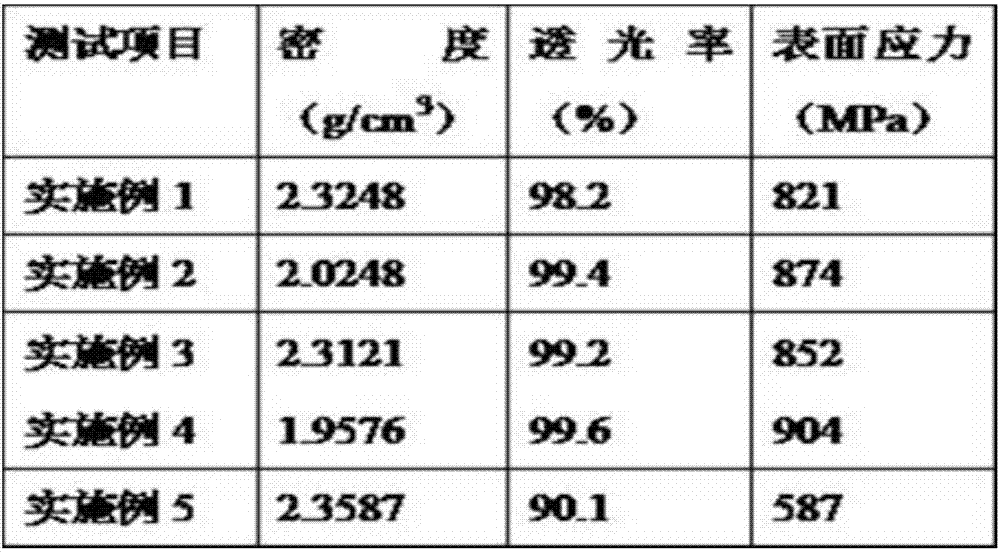

Examples

Embodiment 1

[0017] A modified glass for thin-film solar cells, comprising the following components in parts by weight: 60 parts of silicon dioxide, 13 parts of aluminum oxide, 24 parts of sodium oxide, 10 parts of potassium carbonate, 2 parts of zinc oxide, borax 25 parts, 34 parts of sodium nitrate, 1 part of cobalt oxide, 43 parts of sodium chloride, 24 parts of graphite, 24 parts of manganese powder, 1 part of quartz sand, 34 parts of nickel oxide, 13 parts of calcium oxide, 34 parts of chromium oxide, bamboo fiber 3 parts, 1 part antioxidant, 1 part sodium hydroxide.

[0018] The preparation method of the above-mentioned modified glass for thin film solar cells comprises the following steps: step 1, weighing each component; step 2, mixing silicon dioxide, aluminum oxide, sodium oxide, potassium carbonate, zinc oxide, borax, boric acid Sodium, cobalt oxide, sodium chloride, graphite, manganese powder, quartz sand, nickel oxide, calcium oxide, and chromium oxide are put into the reactor...

Embodiment 2

[0023] A kind of modified glass for thin film solar cells, comprising the following components in parts by weight: 72 parts of silicon dioxide, 35 parts of aluminum oxide, 28 parts of sodium oxide, 14 parts of potassium carbonate, 7 parts of zinc oxide, borax 32 parts, 41 parts of sodium nitrate, 4 parts of cobalt oxide, 52 parts of sodium chloride, 38 parts of graphite, 34 parts of manganese powder, 32 parts of quartz sand, 48 parts of nickel oxide, 18 parts of calcium oxide, 48 parts of chromium oxide, bamboo fiber 7 parts, antioxidant 3 parts, sodium hydroxide 2 parts.

[0024] The preparation method of the above-mentioned modified glass for thin film solar cells comprises the following steps: step 1, weighing each component; step 2, mixing silicon dioxide, aluminum oxide, sodium oxide, potassium carbonate, zinc oxide, borax, boric acid Sodium, cobalt oxide, sodium chloride, graphite, manganese powder, quartz sand, nickel oxide, calcium oxide, and chromium oxide are put int...

Embodiment 3

[0029] A kind of modified glass for thin-film solar cells, comprising the following components in parts by weight: 80 parts of silicon dioxide, 43 parts of aluminum oxide, 53 parts of sodium oxide, 28 parts of potassium carbonate, 9 parts of zinc oxide, borax 35 parts, 53 parts of sodium nitrate, 5 parts of cobalt oxide, 56 parts of sodium chloride, 54 parts of graphite, 43 parts of manganese powder, 34 parts of quartz sand, 54 parts of nickel oxide, 26 parts of calcium oxide, 54 parts of chromium oxide, bamboo fiber 9 parts, antioxidant 4 parts, sodium hydroxide 4 parts.

[0030] The preparation method of the above-mentioned modified glass for thin film solar cells comprises the following steps: step 1, weighing each component; step 2, mixing silicon dioxide, aluminum oxide, sodium oxide, potassium carbonate, zinc oxide, borax, boric acid Sodium, cobalt oxide, sodium chloride, graphite, manganese powder, quartz sand, nickel oxide, calcium oxide, and chromium oxide are put int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| surface stress | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com