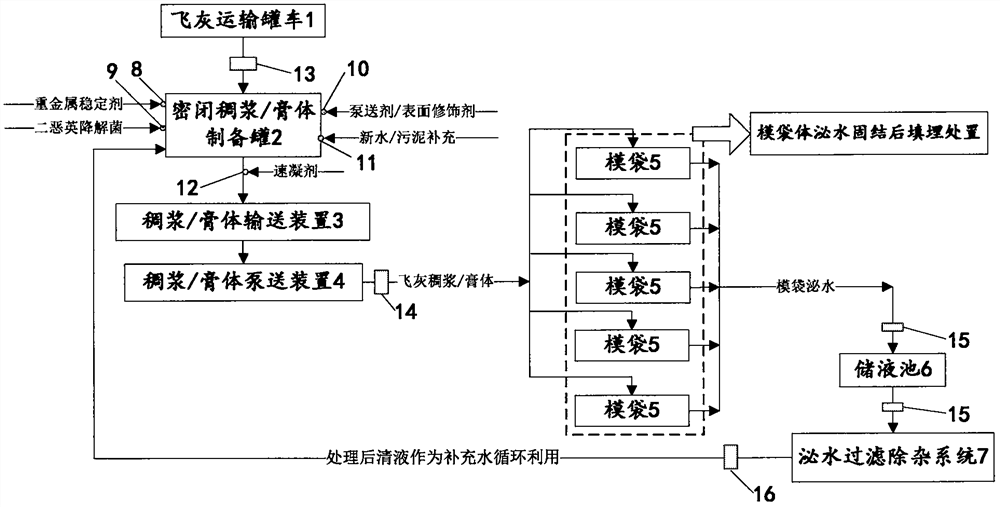

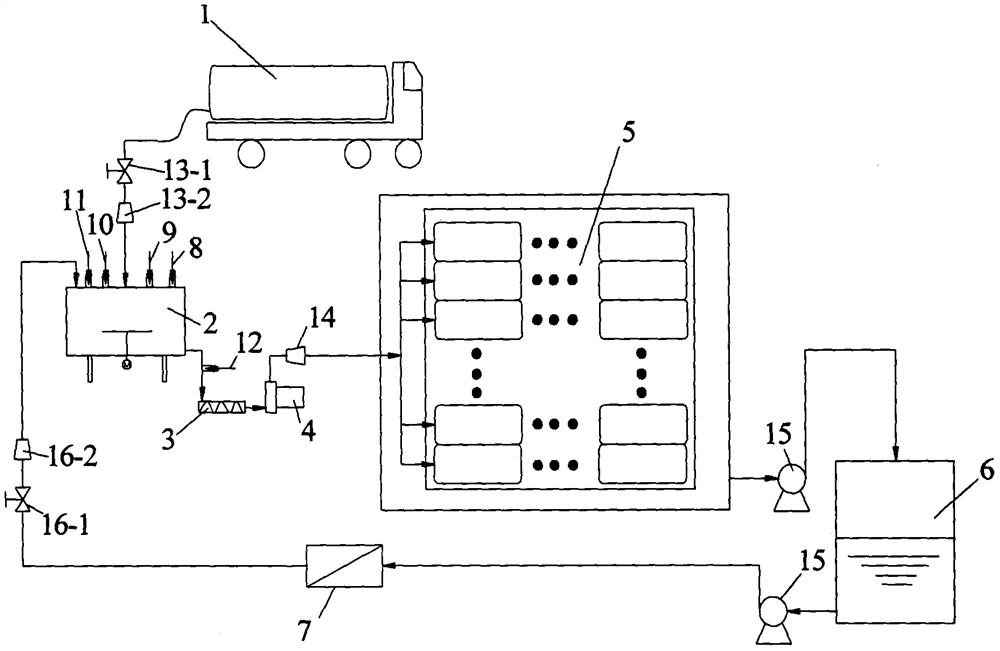

A method and system for treating domestic waste incineration fly ash with high concentration wet injection mold bag

A technology of domestic waste incineration and treatment method, which is applied in the field of domestic waste incineration fly ash high-concentration wet infusion mold bag treatment field, can solve the problem of large fluctuation of fly ash composition, inevitable landfill leachate treatment problems, and the inability of chelating agents to function. Effectively exert the problems such as easing the land resource shortage, expanding the storage capacity utilization coefficient, and expanding the storage capacity utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Example 1: The ratio of fly ash and water to make thick slurry is 1:0.7 by weight, and the water used is the circulating water and new water treated by the bleeding filtration system in the bleeding water treatment system, and the heavy metals are stable. The agent is mercaptoamine salt, the addition amount is 1.2% of the dry basis of fly ash, the dioxin-degrading bacteria is Fusarium oats, the material of the mold bag is polypropylene, and the outer surface of the mold bag is sprayed with a fluorine-containing organosiloxane water-repellent finishing agent , the length of the mold bag is 20m, and 5 injection ports are set. The mold bag is filled with fly ash thick slurry and left for 2 days to achieve complete homogenization, fly ash detoxification and harmlessness, and bleeding / hydration consolidation.

[0050] After bleeding / hydration consolidation, the moisture content of fly ash, dioxins, and heavy metal leaching indexes in the mold bag meet the requirements of "Sta...

Embodiment 2

[0056] Embodiment 2: The ratio of fly ash and water to make paste is 1:0.4 by weight. The body and the addition amount are 1.5% of the dry basis of the fly ash, the dioxin degrading bacteria are Coriolus versicolor, the pumping agent is the liquid concrete pumping agent, and the addition amount is 1.0% of the dry basis of the fly ash, and the surface modifier is Polyacrylamide, adding 1.2% of fly ash dry basis, the mold bag is made of high-strength polypropylene, high-pressure infusion to obtain a high-density infusion mold bag, the outer surface of the mold bag is sprayed with fluorine-containing organosiloxane water-repellent finishing agent, the length of the mold bag is 50m , set 10 perfusion ports, the mold bag is filled with fly ash paste and left for 1.0 days to achieve complete homogenization, detoxification of fly ash, and bleeding / hydration consolidation; More than 2.0t / m3.

[0057] After bleeding / hydration consolidation, the moisture content of fly ash, dioxins, an...

Embodiment 3

[0062] Embodiment 3: fly ash and municipal sludge with water content of 95% are stirred to prepare paste, the ratio is 1:0.35 by weight, heavy metal stabilizer selects EDTA linker polymer, the addition amount is 1.8% of fly ash dry basis, dioxin Cyclic ether degrading bacteria were used as the British degrading bacteria, liquid concrete pumping agent was used as the pumping agent, and the addition amount was 1.2% of the dry basis of fly ash. The bag is made of high-strength polyester, high-pressure infusion to obtain a high-density infusion mold bag, the outer surface of the mold bag is sprayed with a fluorine-containing organosiloxane water-repellent finishing agent, the mold bag length is 40m, and 8 infusion ports are set. After the mold bag is filled with fly ash paste Allow to stand for 1.5 days to achieve complete homogenization, detoxification of fly ash, and bleeding / hydration consolidation; the density of the moulded bag body after bleeding and consolidation is greater ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com