Fluorescent magnetic powder-based intelligent defect identification system

A defect recognition, fluorescent magnetic powder technology, applied in character and pattern recognition, material magnetic variables, image data processing, etc., can solve problems such as damage to health, low efficiency, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

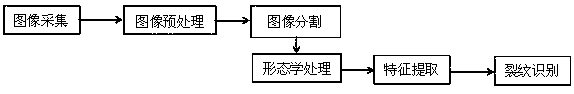

[0035] Such as figure 1 As shown, a flow chart of an intelligent defect recognition system based on fluorescent magnetic particles, the system mainly includes scene depth information acquisition, magnetic mark image preprocessing, image segmentation, morphological processing and feature extraction, and crack recognition.

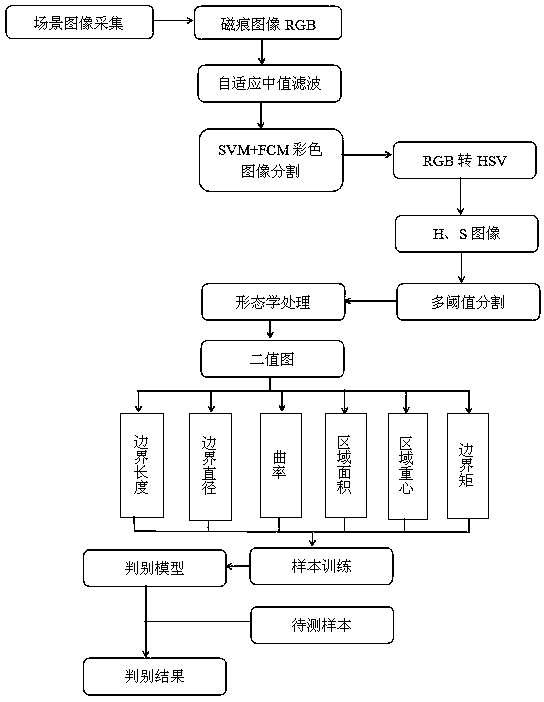

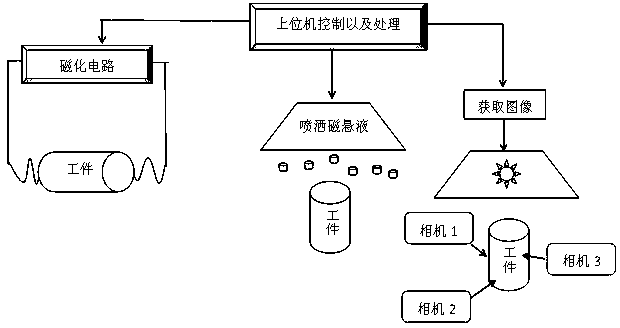

[0036] Such as figure 2 As shown, a block diagram of an intelligent defect recognition system based on fluorescent magnetic powder. First, the image of the workpiece is obtained from the specific factory environment, and then the RGB image of the magnetic mark is transmitted to the host computer. Firstly, the adaptive median filtering is carried out, and then the color image segmentation method of SVM+FCM is used for processing. Afterwards, the segmented color image is converted into an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com