Optical fiber interference confocal system for on-line inspection of processing quality of optical components

A technology of optical components and processing quality, applied in the field of optical fiber interference confocal systems, can solve the problems of inability to guarantee surface roughness and sub-surface detection, inability to truly evaluate the processing quality of the measured area, and extremely high detection environment requirements. High-resolution confocal microscopy imaging, strong anti-interference ability, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

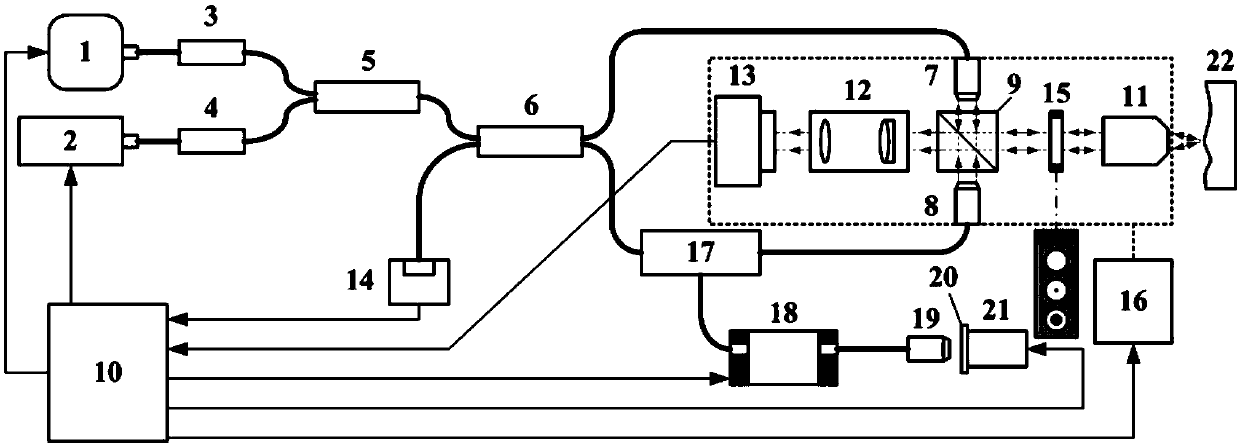

[0025] Such as figure 1 As shown, the optical fiber interference confocal system used for on-line detection of optical element processing quality in the present invention includes a light source switching device, a white light interference device, a laser confocal device, a computer 10, a CCD camera 13 connected to the computer, and a photodetector 14 , five-dimensional motion table 16; wherein, the light source switching device is composed of a broadband light source 1, a laser light source 2, a first fiber isolator 3, a second fiber isolator 4 and a 2×1 fiber coupler 5; the white light interference device adopts Mach- The Zehnder interference structure consists of a 2×2 fiber coupler 6, a first fiber collimator 7, a second fiber collimator 8, a bandwidth splitting prism 9, a fiber circulator 17, an optical delay line 18, and a th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com