A kind of preparation method of bulletproof helmet

A bulletproof helmet and helmet body technology, applied in protective equipment, protective equipment, chemical instruments and methods, etc., can solve the problems of uncomfortable wearing, limited elastic modulus and tensile strength, and large helmet dent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

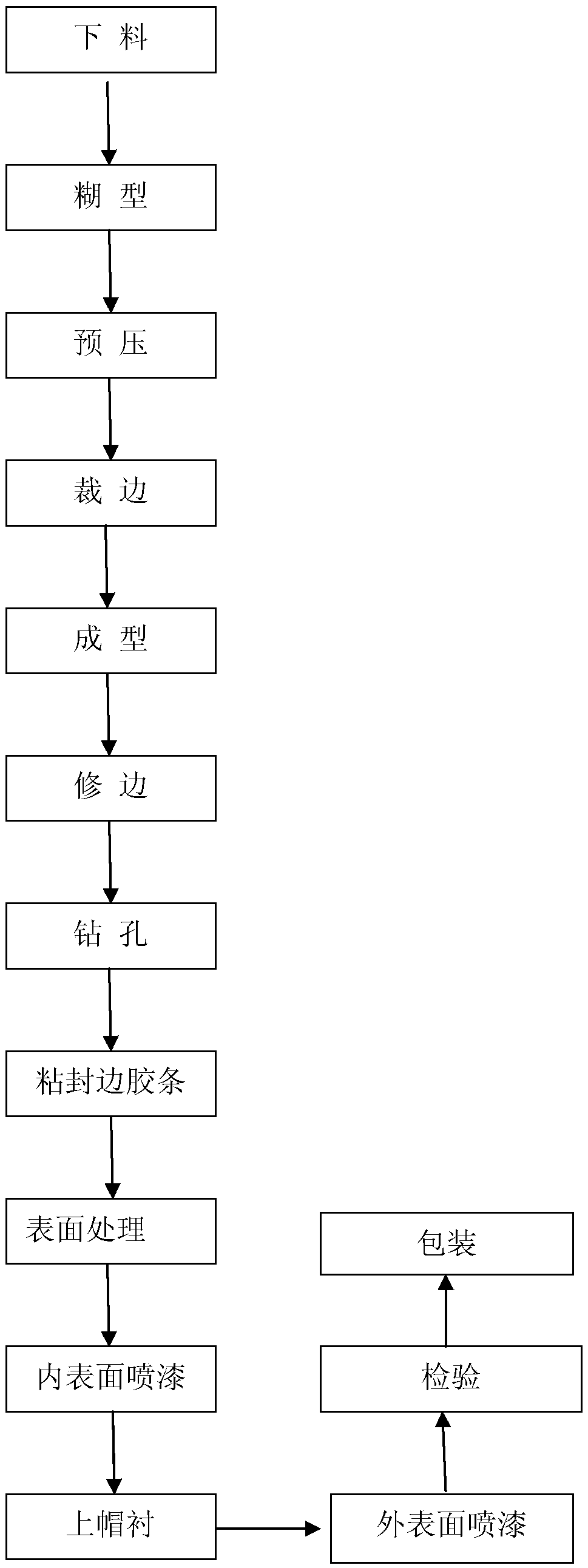

[0035] The technological process of making bulletproof helmets is as follows:

[0036] 1. Cutting:

[0037] According to the requirements, use a pencil to draw lines on the aramid cloth according to the template, a total of 16 specifications, and then use an automatic sharpening and cutting machine to cut according to the lines. No. 1-8 is aramid fiber II, and No. 9-16 is aramid fiber III. Finally, use a band saw cutting machine to cut and trim No. 1-16.

[0038] technical standard:

[0039] (1) Typesetting and cutting according to the requirements.

[0040] (2) Mark the number of layers of the blank according to the specified requirements.

[0041] Process requirements:

[0042] (1) When spreading the cloth, the edge of the cloth should be aligned with one side, and the order of cutting should be based on the small piece first.

[0043] (2) When cutting, it should be cut strictly according to the line to prevent cutting and uneven secant lines.

[0044] (3) Mark and com...

Embodiment 2

[0146] Utilize the bombardment result of the ballistic helmet described in the embodiment 1 that aramid fiber Ⅱ and aramid fiber Ⅲ mix and make as follows table: Ministry of Public Security two grades, 51 formula 7.62mm pistol bullets (lead core)

[0147] serial number

[0148] The ballistic results of bulletproof helmets made of aramid Ⅱ on the market are as follows:

[0149] Ministry of Public Security Level 2, Type 51 7.62mm pistol bullet (lead core)

[0150] serial number

[0151] From the data in the above scale, it can be seen that the sag is significantly reduced. The size of the helmet sag is a direct standard to measure the bulletproof performance of the helmet, and it is also an important indicator to measure the quality of the helmet. Because the helmet sag is too large, it will cause damage to the human head. The injury directly threatens life and health, and the dent of the helmet used is an important symbol to measure the quality of the helmet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com