Self-propelled tunnel ultra-long inverted arch movable template steel box girder trestle

A mobile formwork and self-propelled technology, which is applied in tunnels, tunnel linings, pedestrian bridges, etc., can solve the problems of low walking efficiency of the main bridge, tilted trestle bridge, and large construction span, and achieves improved walking efficiency, easy work, and stable structure good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment is used in the occasion where the concrete construction area needs to be filled across the inverted arch during tunnel construction.

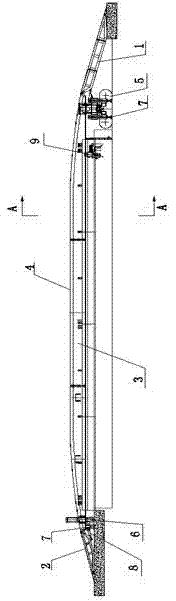

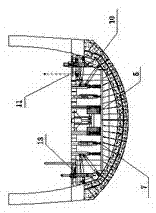

[0036] Such as figure 1 and figure 2 As shown, a self-propelled tunnel ultra-long inverted arch mobile formwork steel box girder trestle includes a front approach bridge 1, a rear approach bridge 2 and a main bridge 3, and also includes a walking device and a utility for moving the trestle under the main bridge 3. As a supporting device for bearing the working weight of the trestle bridge, the walking device includes a traveling drive device arranged in front of the main bridge 3 and a walking driven device arranged behind the main bridge 3, and the supporting device is arranged at the front and rear ends of the main bridge 3 , the running gear and the supporting gear are directly installed on the main bridge 3 . The front approach bridge 1 is used to overlap to form a transition between the excavation front and the b...

Embodiment 2

[0044] This embodiment is used in the occasion where the concrete construction area needs to be filled across the inverted arch during tunnel construction.

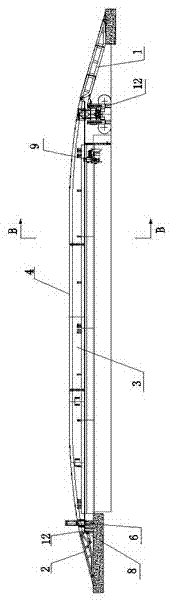

[0045] Such as image 3 and Figure 4 As shown, a self-propelled tunnel ultra-long inverted arch mobile formwork steel box girder trestle includes a front approach bridge 1, a rear approach bridge 2 and a main bridge 3, and also includes a walking device and a utility for moving the trestle under the main bridge 3. As a supporting device for bearing the working weight of the trestle bridge, the walking device includes a traveling drive device arranged in front of the main bridge 3 and a walking driven device arranged behind the main bridge 3, and the supporting device is arranged at the front and rear ends of the main bridge 3 , the running gear and the supporting gear are directly installed on the main bridge 3 . The front approach bridge 1 is used to overlap to form a transition between the excavation front and the br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com