Modular assembled wall body and assembling method thereof

A prefabricated and modular technology, applied in the direction of walls, thermal insulation, manufacturing tools, etc., can solve the problems of no thermal insulation, poor sound insulation effect, difficult construction, slow construction, etc., achieve good thermal insulation and sound insulation effects, simple structure and easy construction convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

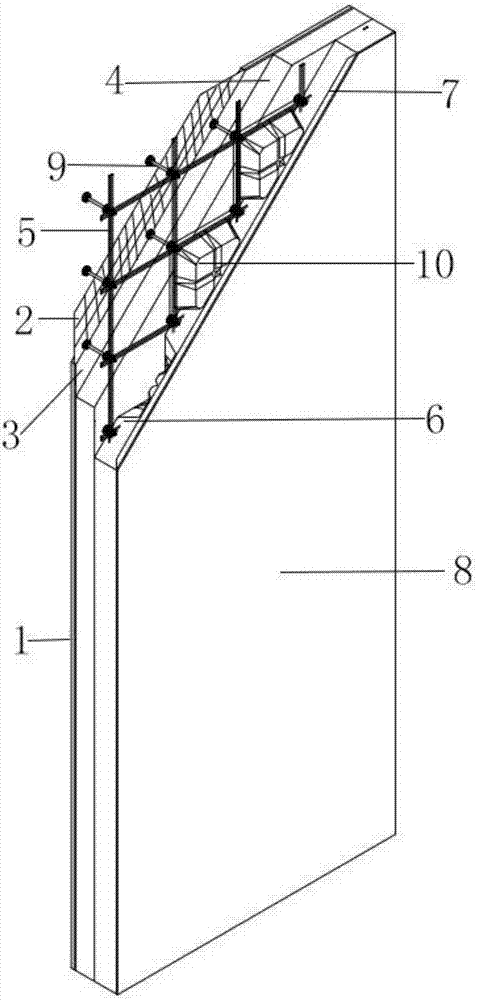

[0024] As shown in the figure, a modular prefabricated wall includes: cement protection layer 1, steel wire mesh 2, first cement layer 3, insulation layer 4, at least one layer of steel mesh 5, second cement layer 6, glass fiber mesh 7. The interior decoration layers 8 are arranged in sequence. The steel wire mesh 2 and the steel mesh 5 are connected by a plurality of tie rods 9 to form an internal bracket supporting the wall; the mesh structure of the steel mesh 5 is a rectangular space, and each of the rectangular spaces is fixedly installed Formwork 10 is arranged; Concretely, reinforcement mesh 5 forms the network with a plurality of rectangular grids by mutually vertical arrangement of a plurality of steel bars, and formwork 10 is installed in each reinforcement mesh 5 grids, and the quantity of formwork 10 can be One, two, four etc., concrete quantity is determined with the size of grid and formwork 10. The present invention supports the formwork 10 in the middle of the...

Embodiment 2

[0038] Embodiment 2 of the present invention provides a method for assembling a modular prefabricated wall, the method comprising the following steps:

[0039] Step S1, the insulation layer is fixed on the plurality of tie rods through the rods of the plurality of tie rods;

[0040]Specifically, the thermal insulation layer and a plurality of tie rods form a prefabricated integral structure, wherein the side of the thermal insulation layer close to the interior decoration layer can be provided with a protective plate, wherein the protective plate can have a defensive function, such as in special cases, such as War chaos, riots, etc., the protective plate can be a bulletproof steel plate. The protective plate can have a heating or cooling function, such as a radiator, etc., or can be pre-embedded into other equipment.

[0041] Step S2, fixing the steel wire mesh by the steel wire mesh holding parts of the plurality of tie rods;

[0042] In step S3, the reinforcing part of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com