Air permeable electrode and preparation method thereof

A technology of electrodes and working electrodes, which is applied in the field of electrodes, can solve the problems of reduced electrode current efficiency, short electrode service life, increased power consumption and salt consumption, etc., and achieve dense oxide coating, increased specific surface area, and improved electrolysis efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

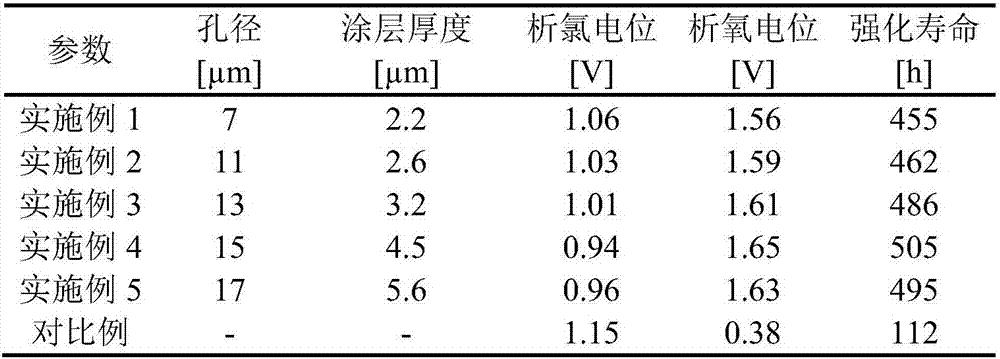

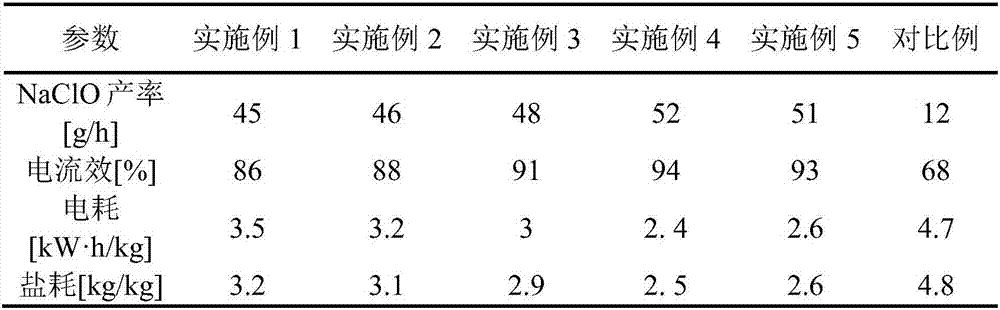

Embodiment 1

[0024] A method for preparing a gas-permeable electrode, comprising the following steps:

[0025] 1) Making a porous titanium substrate: a porous titanium plate with a porosity of 35%, a pore diameter of 7 μm, and a thickness of 1 mm was prepared as a titanium substrate by vacuum sintering;

[0026] 2) Surface treatment of the titanium substrate: place the titanium substrate in a 10wt% NaOH solution and vibrate for 30 minutes, rinse and dry, place it in a 20wt% oxalic acid solution and boil for 2 hours, take it out, rinse it and set it aside;

[0027] 3) Precursor deposition: place the titanium substrate treated in step 2) in an aqueous ethanol solution containing titanium chloride, ruthenium chloride, and iridium chloride at a pH of 3 for deposition; wherein in the aqueous ethanol solution, the volume ratio of ethanol to water is It is 25:3; the concentration of titanium chloride is 54mM / L, the concentration of ruthenium chloride is 14mM / L, and the concentration of iridium ch...

Embodiment 2

[0031] A method for preparing a gas-permeable electrode, comprising the following steps:

[0032] 1) Making a porous titanium substrate: a porous titanium plate with a porosity of 38%, a pore diameter of 11 μm, and a thickness of 1 mm was prepared as a titanium substrate by vacuum sintering;

[0033] 2) Surface treatment of the titanium substrate: place the titanium substrate in a 10wt% NaOH solution and vibrate for 30 minutes, rinse and dry, place it in a 20wt% oxalic acid solution and boil for 2 hours, take it out, rinse it and set it aside;

[0034] 3) Precursor deposition: place the titanium substrate treated in step 2) in an aqueous ethanol solution containing titanium chloride, ruthenium chloride, and iridium chloride at a pH of 2 for deposition; in the aqueous ethanol solution, the volume ratio of ethanol to water is It is 10:1; the concentration of titanium chloride is 57mM / L, the concentration of ruthenium chloride is 16mM / L, and the concentration of iridium chloride ...

Embodiment 3

[0039] A method for preparing a gas-permeable electrode, comprising the following steps:

[0040] 1) Making a porous titanium substrate: a porous titanium plate with a porosity of 40%, a pore diameter of 13 μm, and a thickness of 1 mm was prepared as a titanium substrate by vacuum sintering;

[0041] 2) Surface treatment of the titanium substrate: place the titanium substrate in a 10wt% NaOH solution and vibrate for 30 minutes, rinse and dry, place it in a 20wt% oxalic acid solution and boil for 2 hours, rinse well, and set aside;

[0042] 3) Precursor deposition: place the titanium substrate treated in step 2) in an aqueous ethanol solution containing titanium chloride, ruthenium chloride, and iridium chloride at a pH of 3 for deposition; wherein in the aqueous ethanol solution, the volume ratio of ethanol to water is It is 10:1; the concentration of titanium chloride is 64mM / L, the concentration of ruthenium chloride is 18mM / L, and the concentration of iridium chloride is 11...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com