Preparation method of Cu<2+>-chelated hydroxypropyl polymethacrylate supermacroporous crystal gel medium

A polyhydroxypropyl methacrylate, ultra-large technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of low adsorption capacity, complicated preparation process, small specific surface area, etc., and achieve large specific surface area and thermal stability The effect of good performance and convenient operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] a Cu 2+ The preparation method of chelated polyhydroxypropyl methacrylate super-macroporous crystal gel medium comprises the steps as follows:

[0056] (1) Preparation of polyhydroxypropyl methacrylate super-macroporous crystal gel medium:

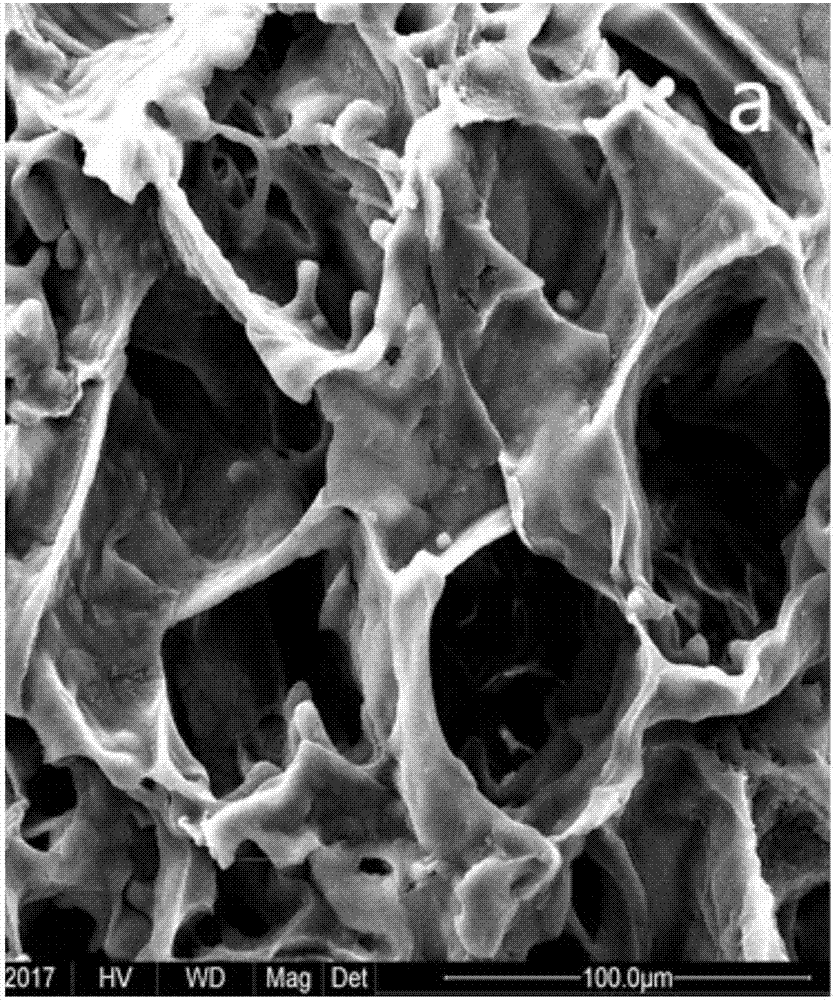

[0057] Dissolve 1.3mL monomer hydroxypropyl methacrylate and ligand material glycidyl methacrylate 0.1mL in 5mL deionized water, and dissolve 0.283g cross-linking agent N'N-methylenebisacrylamide (MBAAm) in 10mL of deionized water, after completely dissolved, mixed to form a solution with a volume fraction of about 10.9%; filled with nitrogen for 20min, under the premise of nitrogen protection, added initiator APS 0.02g, ice-bathed for 30min, and then quickly added catalyst TEMED 25μL, After stirring, quickly transfer it to a syringe (5mL, id=1.3cm), lower the temperature in a constant temperature tank at 0.15°C / min and react at a constant temperature of -16°C for 24h; after the reaction, dissolve at 25°C for 16h, deionize Washing...

Embodiment 2

[0067] a Cu 2+ The preparation method of chelated polyhydroxypropyl methacrylate super-macroporous crystal gel medium comprises the steps as follows:

[0068] (1) Preparation of polyhydroxypropyl methacrylate super-macroporous crystal gel medium:

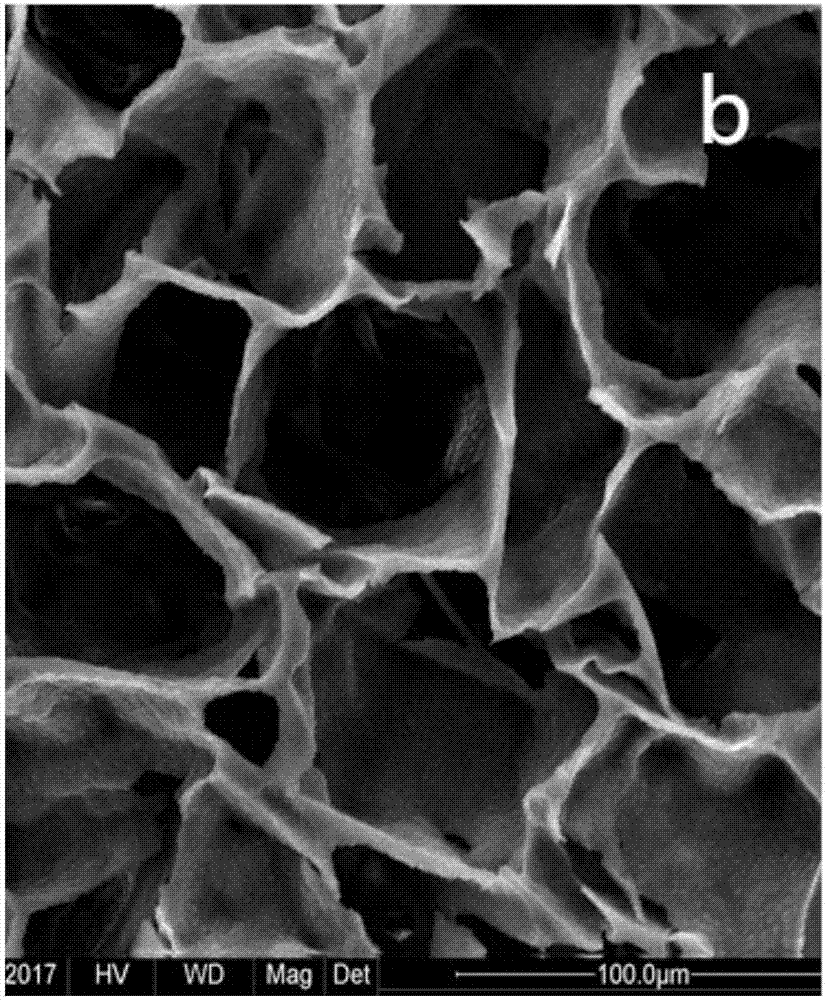

[0069]Dissolve 1.3 mL of monomer hydroxypropyl methacrylate and 0.1 mL of ligand material glycidyl methacrylate in 5 mL of deionized water, and dissolve 0.1 g of cross-linking agent N'N-methylenebisacrylamide (MBAAm) in 10mL of deionized water, after completely dissolved, mixed to form a solution with a volume fraction of about 9.8%; filled with nitrogen for 20 minutes, under the premise of nitrogen protection, added initiator APS 0.02g, ice-bathed for 10 minutes, and then quickly added catalyst TEMED 25μL, After stirring, quickly transfer it to a syringe (5mL, id=1.3cm), lower the temperature in a constant temperature tank at 0.5°C / min and react at a constant temperature of -20°C for 16h; after the reaction, dissolve at 20°C for 2...

Embodiment 3

[0091] a Cu 2+ The preparation method of chelated polyhydroxypropyl methacrylate super-macroporous crystal gel medium comprises the steps as follows:

[0092] (1) Preparation of polyhydroxypropyl methacrylate super-macroporous crystal gel medium:

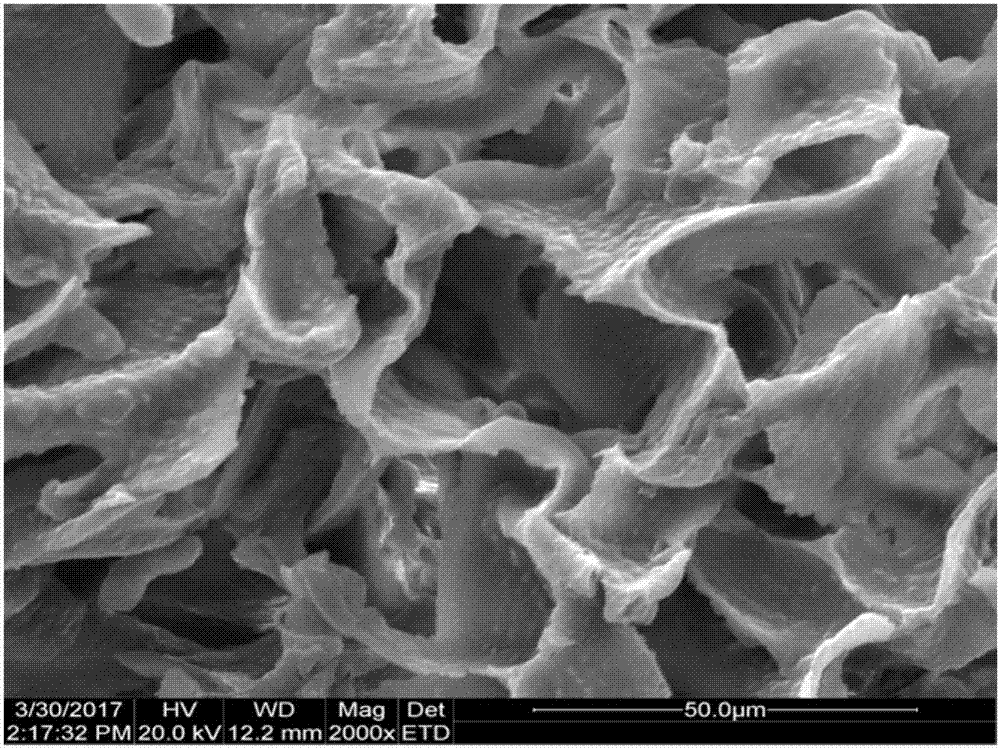

[0093] Dissolve 1.3mL monomer hydroxypropyl methacrylate and ligand material glycidyl methacrylate 0.15mL in 8mL deionized water, and dissolve 0.07g cross-linking agent N'N-methylenebisacrylamide (MBAAm) in 10mL of deionized water, after completely dissolved, mixed to form a solution with a volume fraction of about 8%; filled with nitrogen for 20min, under the premise of nitrogen protection, added 0.02g of initiator APS, ice bathed for 10min, and then quickly added catalyst TEMED 25μL, After stirring, quickly transfer it to a syringe (5mL, id=1.3cm), cool down at 0.15°C / min in a constant temperature tank and react at a constant temperature of -18°C for 30h; after the reaction, dissolve at 27°C for 20h, deionize After washing with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com