Sewage treatment method by using flowing microorganism bed and filtering membrane

A sewage treatment method and filter membrane technology, applied in biological water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of high sewage treatment cost and general treatment effect, and achieve Effects of increasing reproduction speed, saving cost, and saving production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

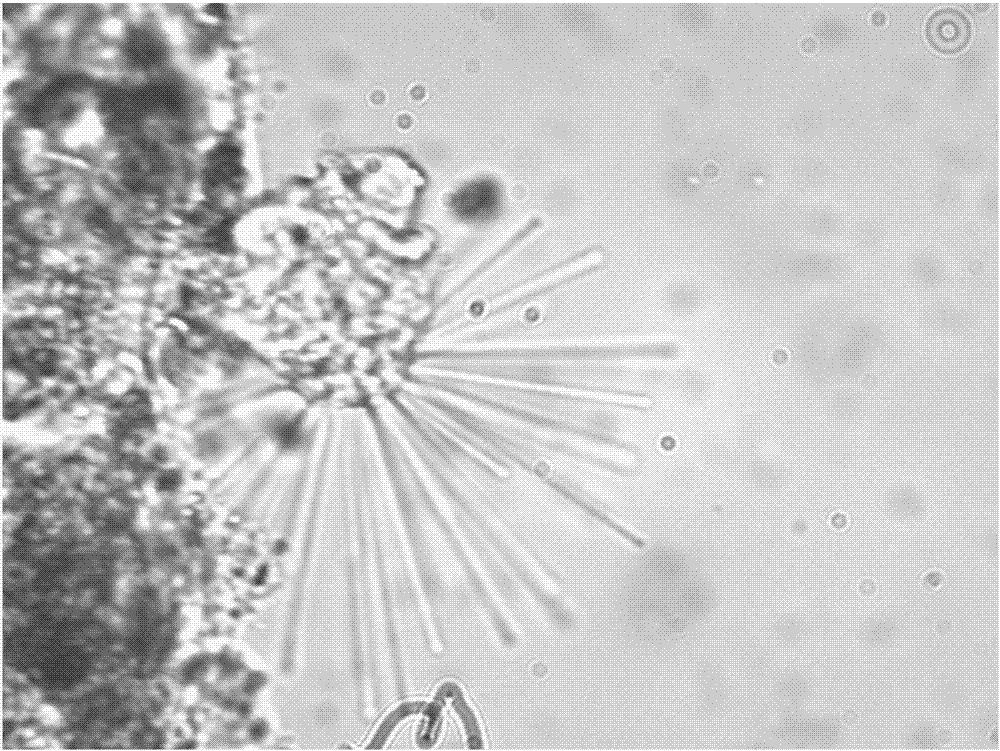

Image

Examples

Embodiment 1

[0064] Embodiment 1: step 1) sewage enters anaerobic pond, has GPB active carrier and active biological protein in anaerobic pond, and GPB active carrier accounts for 25% of the water body volume in anaerobic pond, and GPB active carrier is made of polyurethane water-absorbing gel The porous gel-like carrier; the activated sludge is put into the anaerobic tank, the input amount of the activated sludge is 5-10% of the volume of the water body in the anaerobic tank, and the input amount of the active biological protein is 0.02%-0.03% of the mass of the activated sludge, The anaerobic tank makes the GPB active carrier flow through the stirring motor;

[0065] Step 2) the sewage treated by the anaerobic tank enters the sedimentation tank one;

[0066] Step 3) The sewage through sedimentation tank one enters the aerobic tank, and there are ACD active carrier and active biological protein in the anaerobic tank; the ACD active carrier accounts for 25% of the water body volume in the ...

Embodiment 2

[0111] Embodiment 2: a kind of sewage treatment method that utilizes flowing microbial bed and filter membrane, and the difference of embodiment 1 is: active biological protein comprises 38 parts of buckwheat protein bioactive peptides, 12 parts of fish skin collagens, bone meal by weight parts 5 servings.

Embodiment 3

[0112] Embodiment 3: a kind of sewage treatment method utilizing flowing microbial bed and filter membrane, and the difference of embodiment 1 is: active biological protein comprises 20 parts of buckwheat protein bioactive peptides, 27 parts of fish skin collagens, bone powder by weight parts 6 servings.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com