3D printer and 3D printing method of sodium alginate hydrogel

A 3D printer, sodium alginate technology, applied in medical science, processing and manufacturing, liquid material additive processing, etc., can solve problems such as tissue engineering that cannot be practically used, achieve large-scale promotion and application, good biocompatibility , the preparation method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

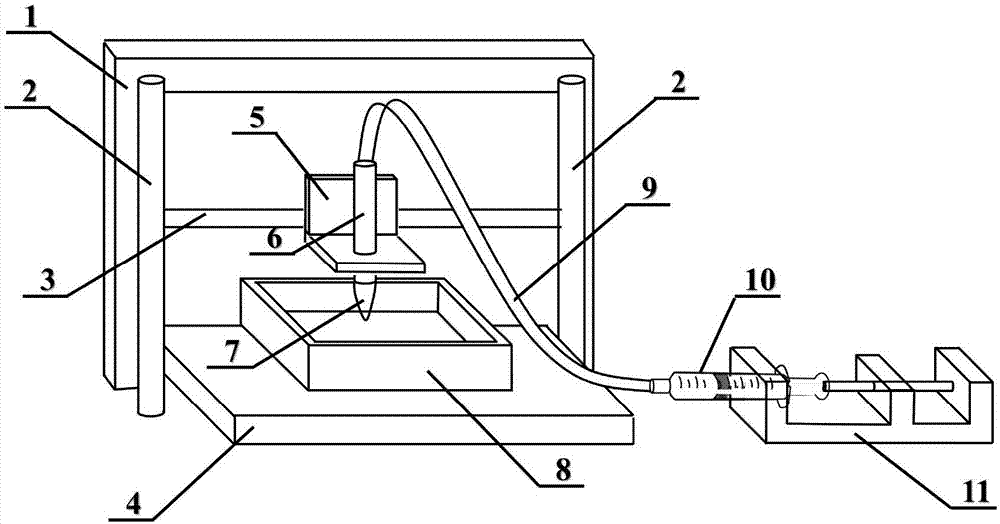

[0037] (1) The 3D printer uses a small 1ml syringe as the hydrogel extruder, the needle diameter of the small syringe is 2mm, and the large syringe is 100ml.

[0038] (2) Prepare sodium alginate aqueous solution for 3D printing ink: Weigh 6 grams of sodium alginate solid powder, dissolve it in 190 ml of deionized water, heat it in a water bath at 60 degrees Celsius, and keep stirring until uniform, and ultrasonically treat it to remove bubbles, that is, viscous sol-like sodium alginate solution.

[0039] (3) Use a 100ml large syringe to absorb the sol-like sodium alginate solution, fix it on the bracket of the peristaltic pump, use a silicone tube with an inner diameter of 3 mm to connect the head of the large syringe and the tail of the small syringe, and pre-fill the sol-like alginate The sodium solution is squeezed into a small syringe filled with silicone tubing, and the extrusion speed of the peristaltic pump is set to 5 ml / min.

[0040] (4) Place a liquid tank on the 3D...

Embodiment 2

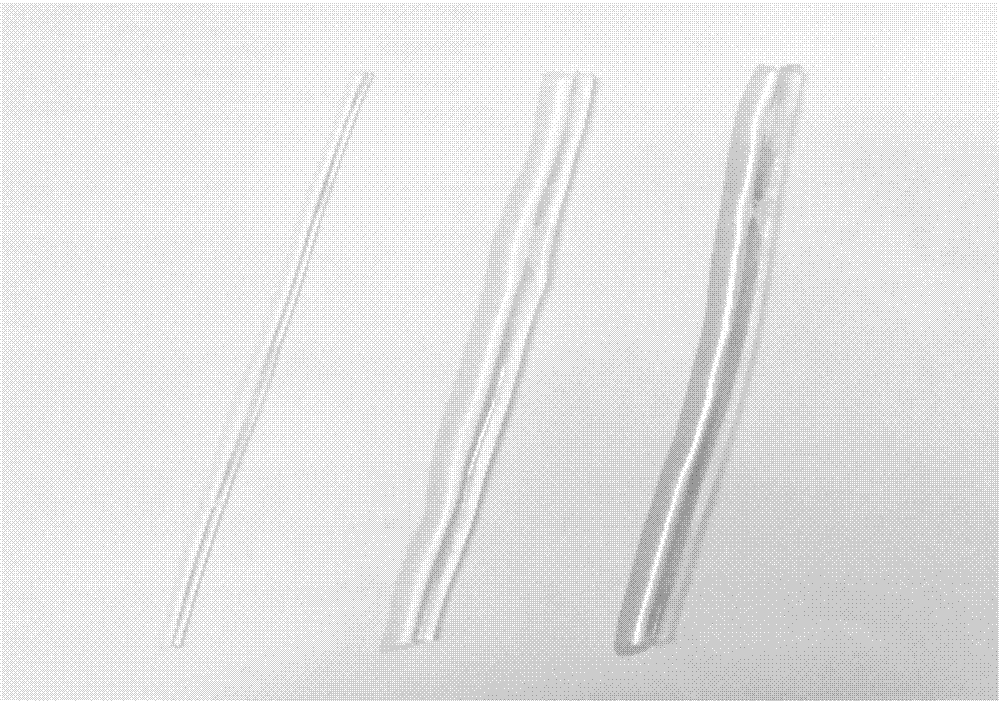

[0045] Utilize the 3D printer of the present invention, adopt the small syringe needle that pipe diameter is 4 millimeters. The preparation and printing steps of the printing material are the same as the steps (2) to (7) of Example 1, wherein the extrusion speed of the peristaltic pump is changed to 10 ml / min. Take out the formed hydrogel from the calcium ion solution and print out continuous, uniformly thick and thin line-shaped hydrogel. The hydrogel of this example is thicker than the hydrogel obtained in Example 1, as figure 2 As shown in the middle picture.

Embodiment 3

[0047] Utilize the 3D printer of the present invention, adopt the small syringe needle that pipe diameter is 4 millimeters. When preparing the sodium alginate aqueous solution for 3D printing ink, add methyl orange as a color reagent. The specific method is: weigh 6 grams of sodium alginate solid powder and 0.5 mg of methyl orange powder, dissolve them in 190 ml of deionized water, Heated in a water bath at 60 degrees Celsius, and continued to stir until uniform, and ultrasonically treated to remove air bubbles, and an orange sol-like sodium alginate solution was obtained. The printing steps are the same as the steps (3) to (7) of Example 1, and the orange continuous, uniform thickness linear sodium alginate hydrogel can be obtained. The thickness of the hydrogel in this example is equivalent to that of the hydrogel obtained in Example 2. ,Such as figure 2 Shown on the right.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com