Plastic uptake forming method, plastic uptake forming machine and auxiliary devices

A technology of blister forming machine and auxiliary device, which is applied to other household appliances, household appliances, household components, etc., which can solve the problems of stretching thinning, stretching damage, and drastic texture changes, and achieve the effect of ensuring stretching performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

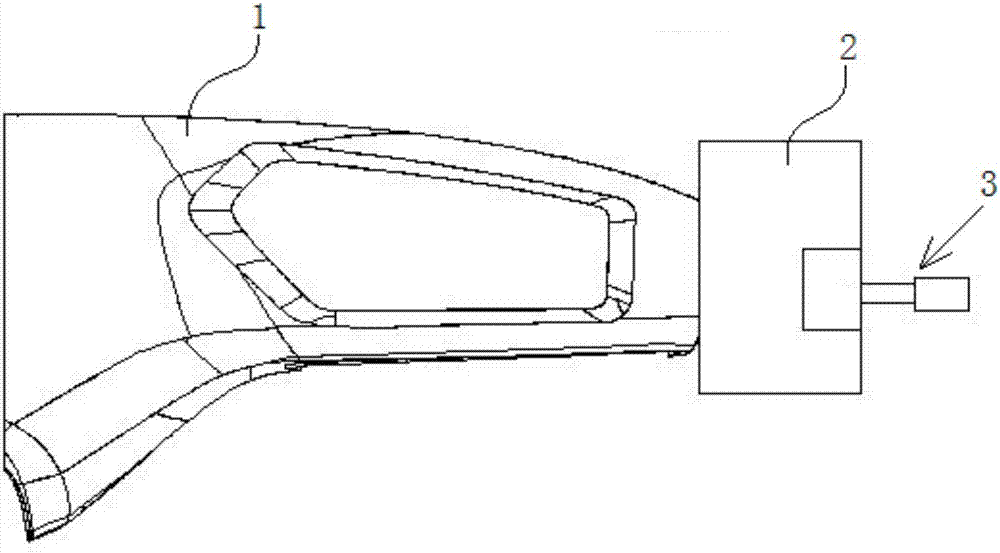

[0051] combine Figure 1-5 , the blister molding machine of this embodiment includes a blister molding machine main body 1 and a blister molding machine auxiliary device 3, and several blister molding machine auxiliary devices 3 are distributed around the blister molding machine main body 1 for forming a blister The edge part of the product 2 covered on the main body 1 of the molding machine is moved to the designated position.

[0052] The auxiliary device 3 of the blister forming machine includes: a pressure part 301, which is used to contact the edge part of the product 2; part 301; a power part 303, the power part 303 provides power for the expansion and contraction of the telescopic part 302. Wherein, the pressure part 301 is pressed against the edge part of the product 2, and a sliding block 3013 is arranged on the contact surface between the pressure part 301 and the edge part of the product 2; a heating module for heating the edge part of the product 2 is also arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com