A treatment method for improving rattan weaving performance

A processing method and rattan technology, applied in wood treatment, pretreatment equipment, wood treatment details, etc., can solve the problems of increasing weaving cost, damage to weaving personnel, waste of rattan, etc., to improve the quality of use, dry shrinkage and other problems. The effect of reducing the rate and air-drying shrinkage rate and increasing the number of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

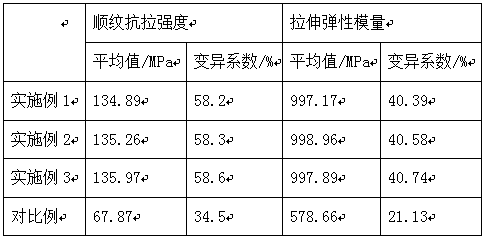

Examples

Embodiment 1

[0018] In the embodiment of the present invention, a kind of treatment method that improves rattan weaving performance, concrete method is as follows:

[0019] (1) First microwave drying, water boiling, second microwave drying and treatment liquid soaking treatment

[0020] Remove the leaves of the rattan, microwave dry at a frequency of 634MHz until the moisture content is 3%, immerse in water at a temperature of 64°C for 21 minutes, boil it on a high fire and continue to simmer for 14 minutes, take it out, and dry it at a frequency of 878MHz Microwave drying under certain conditions until the water content is 4%, immersed in the treatment solution for 49 minutes, and then taken out to obtain pretreated rattan;

[0021] The treatment liquid is made of the following raw materials in parts by weight: 5.7 parts of bitter wood, 3.5 parts of japonica, 8.3 parts of leaking reed, 6.2 parts of Gentiana chinensis, 18.2 parts of fresh Xihuangcao, 21.3 parts of fresh Cordyceps chinensis...

Embodiment 2

[0029] In the embodiment of the present invention, a kind of treatment method that improves rattan weaving performance, concrete method is as follows:

[0030] (1) First microwave drying, water boiling, second microwave drying and treatment liquid soaking treatment

[0031] Remove the leaves of the rattan, microwave-dry at a frequency of 635MHz until the water content is 3.5%, immerse in water at a temperature of 64.5°C for 21.5 minutes, boil it on a high fire, and continue to simmer for 14.5 minutes. Microwave drying under the condition of 879MHz until the moisture content is 4.5%, immersed in the treatment solution for 50 minutes, and then taken out to obtain pretreated rattan;

[0032] The treatment solution is made of the following raw materials in parts by weight: 5.75 parts of bitter wood, 3.55 parts of japonica, 8.35 parts of leaking reed, 6.25 parts of Gentiana chinensis, 18.4 parts of fresh Xihuangcao, 21.5 parts of fresh Dongling grass, fresh orange peel 11.3 parts,...

Embodiment 3

[0037] In the embodiment of the present invention, a kind of treatment method that improves rattan weaving performance, concrete method is as follows:

[0038] (1) First microwave drying, water boiling, second microwave drying and treatment liquid soaking treatment

[0039] Remove the leaves of the rattan, microwave-dry at a frequency of 636MHz until the moisture content is 4%, immerse in water at a temperature of 65°C for 22 minutes, boil it on a high fire and continue to simmer for 15 minutes, take it out, and dry it at a frequency of 880MHz Microwave drying under certain conditions until the moisture content is 5%, immersed in the treatment solution for 51 minutes, and then taken out to obtain pretreated rattan;

[0040] The treatment liquid is made of the following raw materials in parts by weight: 5.8 parts of bitter wood, 3.6 parts of japonica, 8.4 parts of leaking reed, 6.3 parts of Gentiana chinensis, 18.6 parts of fresh Xihuangcao, 21.7 parts of fresh Radix japonicus, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com