A lap resistance welding method for high-strength strip steel with carbon equivalent greater than 0.5

A high-strength, carbon-equivalent technology, applied in resistance welding equipment, welding/welding/cutting items, welding equipment, etc., can solve problems that affect the life of welding wheels, work roll consumption, increase the risk of weld fracture, welding spatter, etc. problems, achieve good toughness and surface quality, increase post-weld annealing function, and economical and reliable control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

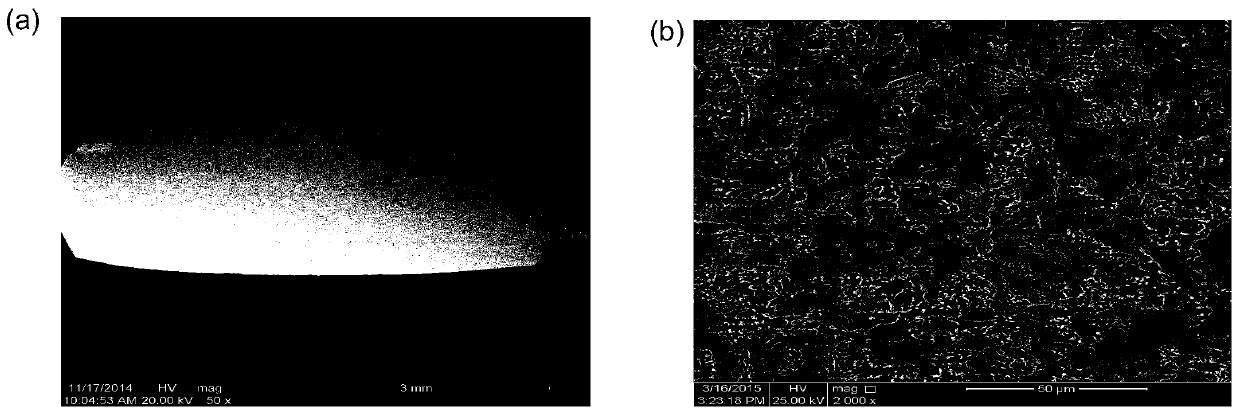

[0041] A lap resistance welding method for 1.8 mm thick thermoformed steel plates with a carbon equivalent of 0.52, the chemical composition and weight percentage of the thermoformed steel plates are: C≤0.30%; Si≤0.50%; Mn≤1.50%; P≤ 0.030%; S≤0.010%; Cr≤0.50%; B≤0.005%; the balance is Fe and other trace elements; the tensile strength R of hard-rolled coils m is 1000MPa.

[0042] The method comprises the steps of:

[0043] (1) Weld high-strength steel plates on narrow lap resistance welding machines;

[0044] The parameters are controlled as follows: the welding current is 25KA; the electrode pressure is 16KN, and the welding speed is 10m / min. The lap on the operating side is 0.9mm, and the lap on the drive side is 2.1mm. The welding seam rolling applied to the overlapping part after welding is 19KN.

[0045] (2) After the welding is completed, enter the post-weld heat treatment process;

[0046] After the welding is completed, it will enter the weld annealing device. The ...

Embodiment 2

[0052] A lap joint resistance welding method of 1.8mm thick 1000MPa grade martensitic dual-phase steel plate with a carbon equivalent of 0.58, the chemical composition and weight percentage of the hot-formed steel plate are: C≤0.25%; Si≤0.80%; Mn≤ 0.80%; P≤0.035%; S≤0.030%; Alt≥0.020%. The balance is Fe and other trace elements; the tensile strength R of its rolled hard coil m It is 1400MPa.

[0053] The method comprises the steps of:

[0054] (1) Weld high-strength steel plates on narrow lap resistance welding machines;

[0055]The parameters are controlled as follows: the welding current is 23KA; the electrode pressure is controlled at 17KN, and the welding speed is 9m / min. The lap on the operating side is 1.1mm, and the lap on the drive side is 2.2mm. The welding seam rolling force applied to the overlapping part after welding is 19KN.

[0056] (2) After the welding is completed, enter the post-weld heat treatment process;

[0057] After the welding is completed, it w...

Embodiment 3

[0063] A lap resistance welding method for 2 mm thick thermoformed steel plates with a carbon equivalent of 0.52, the chemical composition and weight percentage of the thermoformed steel plates are: C≤0.30%; Si≤0.50%; Mn≤1.50%; P≤0.030 %; S≤0.010%; Cr≤0.50%; B≤0.005%; the balance is Fe and other trace elements. The tensile strength R of its rolled hard coil m is 1000MPa.

[0064] The method comprises the steps of:

[0065] (1) Weld high-strength steel plates on narrow lap resistance welding machines;

[0066] Its parameters are controlled as follows: the welding current range is 24KA; the electrode pressure control range is 17KN, and the welding speed range is 8m / min. The overlapping range of the operating side is 1.1mm, and the overlapping amount of the transmission side is 2.3mm. The range of weld rolling applied to the lap joint after welding is 19KN.

[0067] (2) After the welding is completed, enter the post-weld heat treatment process;

[0068] After the welding is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com