Ultraviolet resistant coating clothes

An anti-ultraviolet coating and anti-ultraviolet technology, applied in special outerwear, clothing, clothing, etc., can solve the problems of unstable protective function and easy failure, and achieve the effect of improving functionality and wearing comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

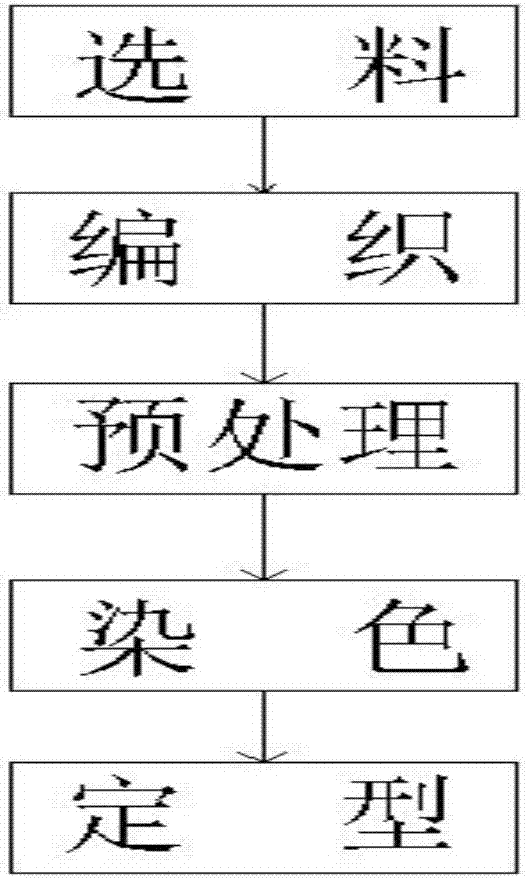

[0009] The present invention is specifically described below in conjunction with accompanying drawing, as figure 1 Shown, a kind of anti-ultraviolet coating clothes, described anti-ultraviolet coating weight ratio is: 2.0% ultraviolet absorber, 2.0% antibacterial agent, 1.0g / L dispersing and leveling agent, 1.0g / L moisture-wicking and soft Agent, 1.0g / L anti-aging agent, 3.0g / L reduction cleaning agent, 1.0g / L antistatic agent, 1.6% fuel are disperse dyes; the synthetic process of described anti-ultraviolet coating and clothes: step 1, select Material, yarn chooses polyester anti-ultraviolet processed silk; step 2, weaving, chooses tight double-sided bird’s-eye structure; the upper machine adopts SD-G-4A double-sided circular weaving machine; step 3, pretreatment, remove the gray fabric oil and dirt; step 4, dyeing, the paint layer and yarn are mixed and dyed; step 5, setting, setting at 100°C at a speed of 18.3m / min.

[0010] The feature of this embodiment is that because th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com