Intensive environmentally-friendly rotary S-shaped fertilizer production equipment

A production equipment and environmental protection technology, applied in the field of intensive environmental protection rotary S-type fertilizer production equipment, can solve the problems of low drying efficiency, large power consumption, large floor space, etc., to improve drying efficiency, reasonable structure design, The effect of high thermal energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

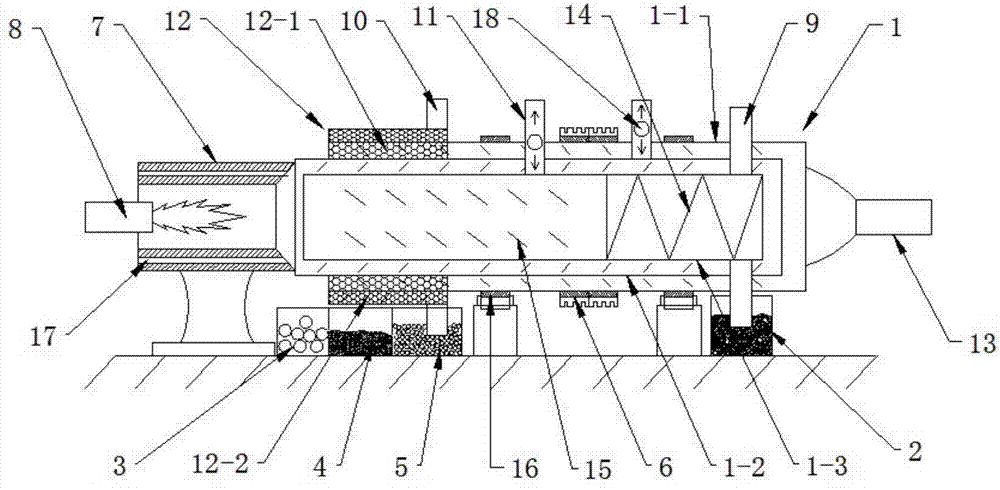

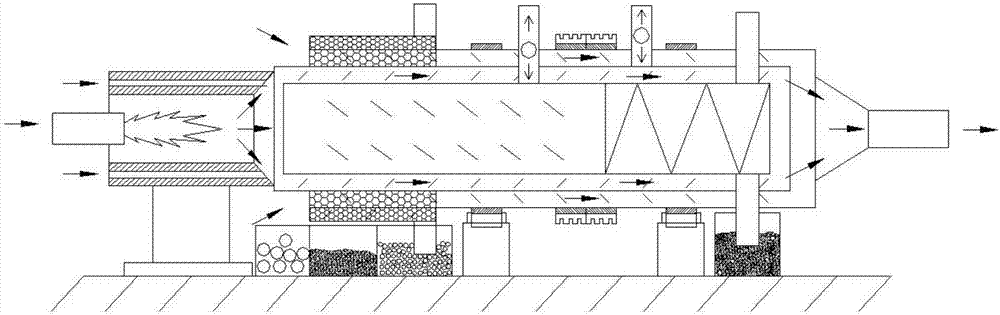

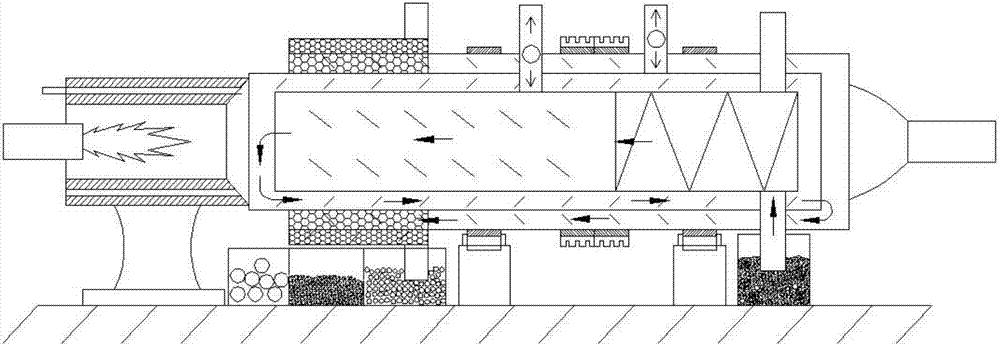

[0016] Such as Figure 1 to Figure 3 As shown, an intensive environment-friendly rotary S-shaped fertilizer production equipment in this embodiment includes a drum 1, a feed bin 2, a large grain bin 3, a small grain bin 4, a finished product bin 5, idler rollers 16, and power transmission gears 6. Air preheater 7, hot blast stove 8, feed hopper elevator 9, discharge hopper elevator 10, double-layer filter device 12 and induced draft fan 13;

[0017] The double-layer filter screen device 12 includes an inner layer of large particle filter screen 12-1 and an outer layer of small particle filter screen 12-2; the small particle bin 4 and the finished product bin 5 are successively arranged on the double-layer filter screen from left to right Below the device 12, the large grain bin 3 is arranged on the left side of the small grain bin 4, the feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com