High-power commercial induction cooker and power control method thereof

A technology for power control and induction cooktops, which is used in household stoves/stoves, induction heating control, electric/magnetic/electromagnetic heating, etc. problems, to meet the cooking needs, to promote the application of good prospects, good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

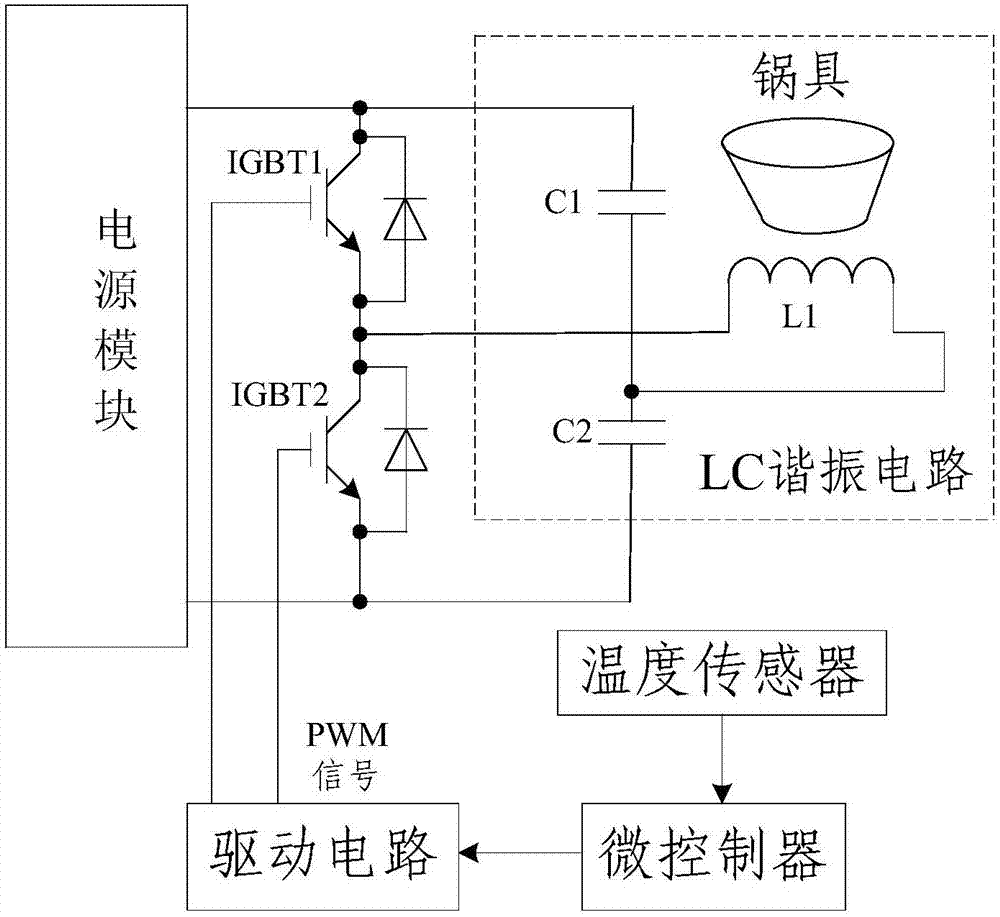

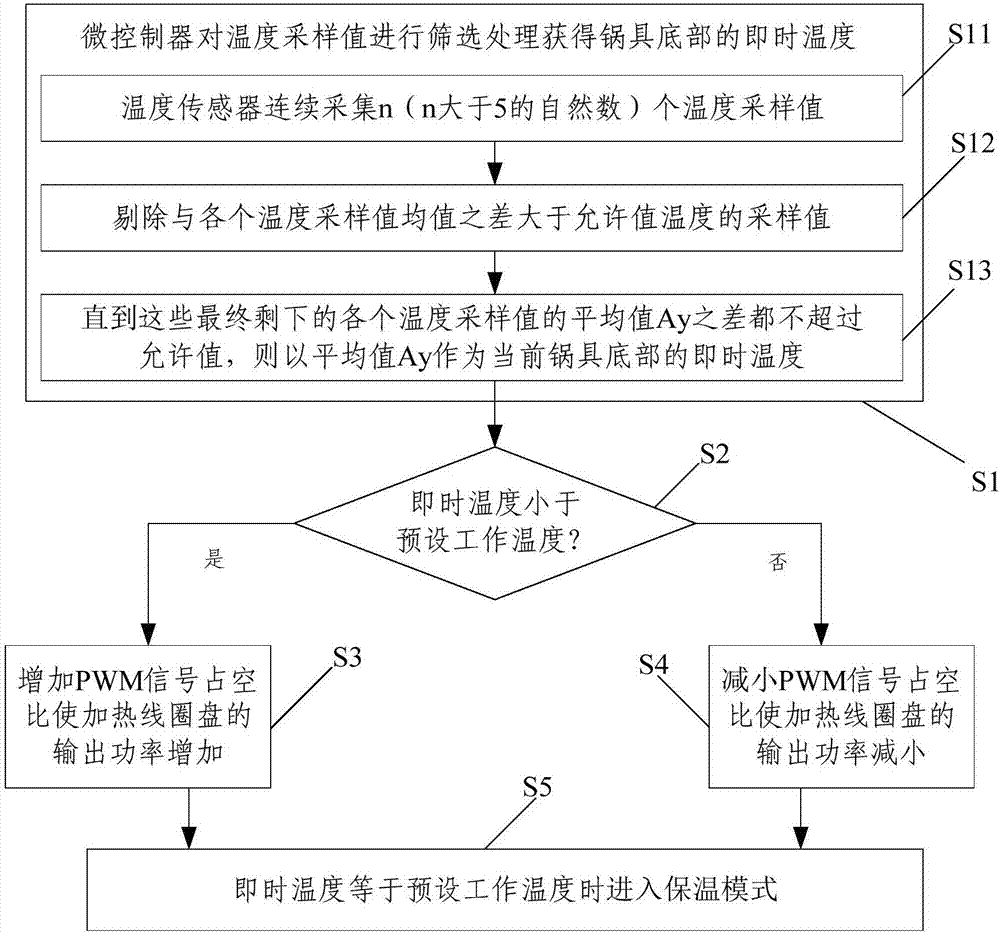

[0024] Such as figure 1 As shown, the present invention proposes a high-power commercial electromagnetic cooker at least including: a power supply module, an inverter circuit composed of two high-power switch tubes IGBT1 and IGBT2, and a resonant capacitor C1, a resonant capacitor C2 and a heating coil plate connected in series L1, and the LC resonant circuit composed of the pot arranged above the heating coil plate L1, connect the microcontroller of the control end of the switching tube IGBT1 and the switching tube IGBT2 through the driving circuit, and the microcontroller is generally realized by a single-chip microcomputer or a DSP controller , and the data port of the microcontroller is connected with one or more temperature sensors, which are thermistors or thermocouples, and are used to measure the temperature of the bottom of the pot.

[0025] The inverter circuit converts the output voltage of the power module into a high-frequency AC signal. The high-frequency AC curr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com