Construction technology for concrete filled steel tube mold bag pile compound retaining structure

A technology of steel pipe concrete and construction technology, which is applied in the direction of foundation structure engineering, underwater structures, artificial islands, etc., and can solve problems such as difficulty in pouring concrete, difficulty in controlling the depth and quality of pile tips entering the bearing layer, and difficulty in protection, etc., achieving Solve the difficulty of controlling the depth and quality of the bearing layer, solve the effect of excavation and support, and reduce the cost of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

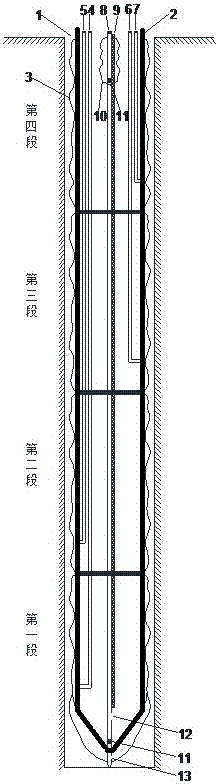

[0023] A construction technique for a composite soil retaining structure of concrete-filled steel tube molded bag piles, the technique comprising the following steps:

[0024] (1), measuring and setting out;

[0025] (2), vertical hole forming;

[0026] (3) Manufacture and installation of steel pipes;

[0027] (4) Fabrication and installation of grouting pipes;

[0028] (5) Drainage system and installation of mold bag making;

[0029] (6), grouting construction technology.

Embodiment 2

[0031] According to the construction technology of the concrete-filled steel pipe molded bag pile composite retaining structure described in Example 1, the method of measuring and setting out in the step (1) is to measure and release the center line and foundation of the steel pipe concrete molded bag pile according to the construction drawings and coordinate points. Plane position line and longitudinal elevation line, make plane and elevation control points, and arrange lifting observation points and observation devices.

Embodiment 3

[0033] According to the construction technology of the concrete-filled steel pipe mold bag pile composite retaining structure described in embodiment 1 or 2, the method for vertically forming holes in the step (2) is to select a drilling rig with a suitable drilling diameter, and the drilling operation platform should be stable. , solid, drilling installation and drilling process must ensure that the inclination is controlled within 1%. During the drilling process, use clean water to circulate and return the water. Rinse the sediment at the bottom of the hole, and ensure that the hole is complete, there is no collapse, and the depth meets the requirements for lowering the mold bag. After passing the acceptance, install the straight segmented mold bag or grouting device in the hole at one time. The hole forming method of the drainage hole is the same as the grouting The holes are the same, and after completion, the drainage device and fine sand for filtering water are lowered, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com