Hole sealing agent, hole sealing process and aluminum alloy product

A sealing agent and hole sealing technology, which is applied in the field of aluminum alloy products and sealing agents, can solve the problem that the sealing agent cannot perform secondary sealing, and achieve anti-pollution effects, good anti-fingerprints, anti-pollution self-purification Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1: The preparation of the sealing agent is as follows: calcium acetate, barium acetate, lithium silicate, ammonium acetate, titanium acetate, sodium fluotitanate and sodium dodecylbenzenesulfonate are dispersed in deionized water to form an emulsion. The content of each component in the emulsion is calculated by weight percentage, including: 30% calcium acetate, 8% barium acetate, 5% lithium silicate, 6% ammonium acetate, 9% titanium acetate, 4% sodium fluotitanate, 1.2% dodecanoate Sodium alkylbenzene sulfonate, the balance is water. The sealed storage time of the above sealing agent can reach more than 1 year.

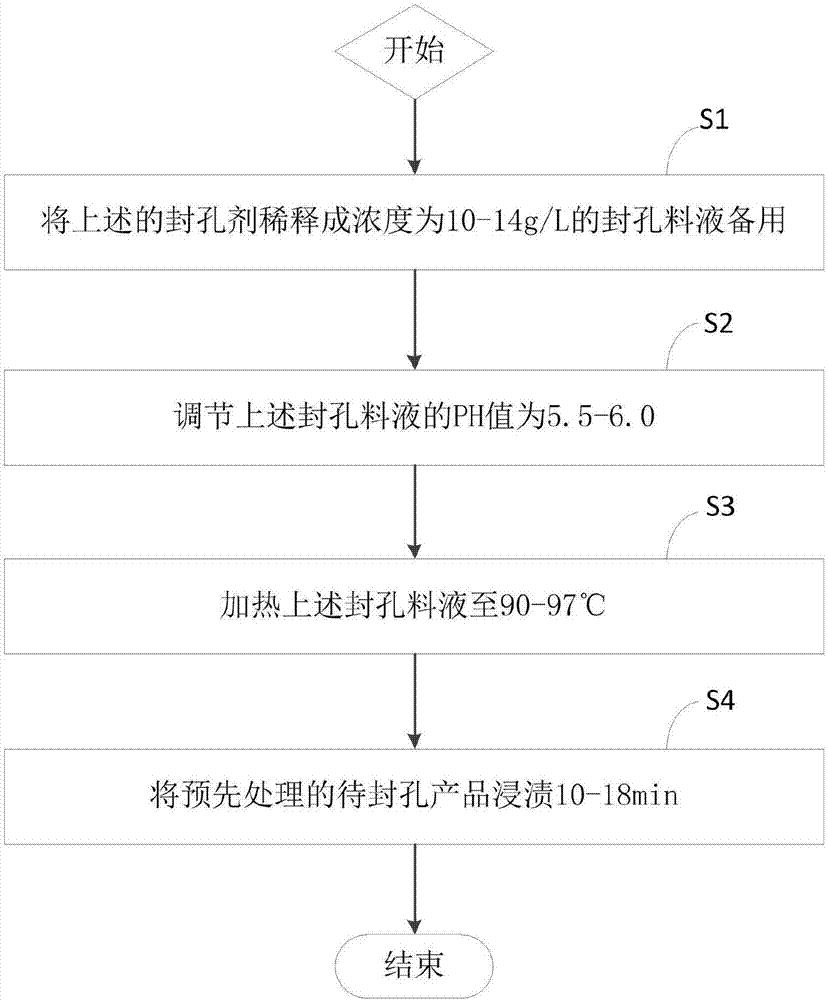

[0044] Dilute the above-mentioned sealing agent into a sealing material solution with a concentration of 12g / L for later use; adjust the pH value of the above-mentioned sealing material solution to 6.0; heat the above-mentioned sealing material solution to 94°C; immerse the pre-treated aluminum alloy product for 15 minutes . That is to make alumin...

Embodiment 2

[0045] Example 2: The composition of the above sealing agent is calculated by weight percentage, including: 20% calcium acetate, 15% barium acetate, 8% lithium silicate, 5% ammonium acetate, 12% titanium acetate, 7% sodium fluotitanate , 1.4% sodium dodecylbenzenesulfonate, other operations are the same as in Example 1. The sealed storage time of the above sealing agent can reach 2 years. In the sealing process, the concentration of the sealing material liquid is 10g / L, the pH value is 5.5; the sealing temperature is 90°C, and the sealing time is 18 minutes, so that the aluminum alloy products can obtain a sealing film with a smooth surface and no powder frost.

Embodiment 3

[0046] Embodiment 3: The composition of above-mentioned sealing agent is calculated by weight percentage, comprises: 20% calcium acetate, 25% barium acetate, 10% lithium silicate, 8% ammonium acetate, 12% titanium acetate, 9% sodium fluotitanate , 4% sodium dodecylbenzenesulfonate, other operations are the same as in Example 1. The sealed storage time of the above sealing agent can reach more than 1 year. In the sealing process, the concentration of the sealing material liquid is 14g / L, the PH value is 6.0; the sealing temperature is 97°C, and the sealing time is 10 minutes, so that the aluminum alloy products can obtain a sealing film with a smooth surface and no powder frost.

[0047] The embodiment of the present invention also proposes an aluminum alloy product, wherein the aluminum alloy product is sealed by the above sealing agent through the above sealing process. The above-mentioned aluminum alloy products have a smooth surface, no powder frost, and no nickel residue,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com