Two-way foamed aluminum ingot casting continuous production line

A foamed aluminum and production line technology, applied to casting equipment, manufacturing tools, equipment for feeding molten metal into molds, etc., can solve problems such as cumbersome process, inability to achieve two-way output, discontinuous production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0068] The embodiments are described below with reference to the accompanying drawings. The embodiments shown below do not limit the invention content described in the claims. required for the solution.

[0069] Such as figure 1 As shown, the two-way foamed aluminum ingot casting continuous production line includes a hot melting furnace 1, and also includes:

[0070] Stirring assembly 2, the stirring assembly 2 is arranged at the discharge end of the hot melting furnace 1 and communicated with it, which is used to stir the molten aluminum output from the hot melting furnace 1;

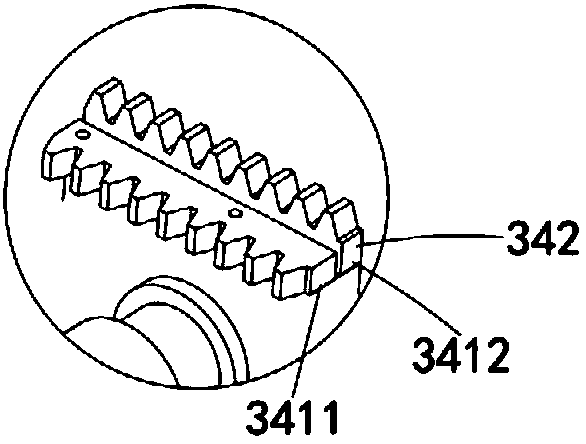

[0071] The first casting line 3, the first casting line 3 is arranged on one side of the hot melting furnace 1, on which a plurality of first casting aluminum molds 31 are equidistantly arranged along its length direction, and the first casting aluminum molds 31 are used To carry the molten aluminum output by the stirring assembly 2 and cast an aluminum ingot 6;

[0072] The second casting line 4, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com