Hot bending film, hot-bending-film fully laminated radian display screen and preparation methods thereof

A display and full lamination technology, applied in the direction of film/flake adhesives, coatings, paints containing biocides, etc., which can solve the problem of all-round protection of OLED screens and can not truly achieve full lamination of OLED screens , can not really achieve full fit and other problems to achieve the effect of improving the display effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

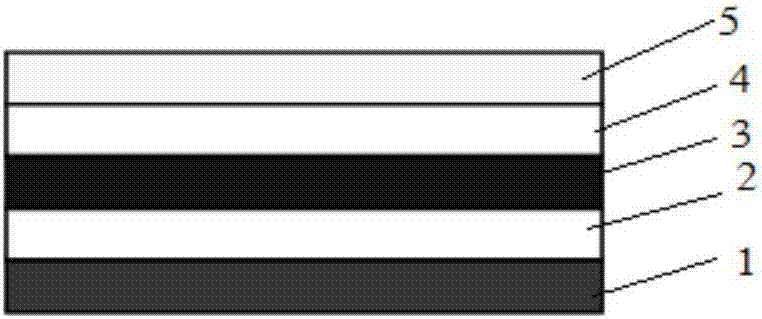

[0075] In this embodiment, the structure of the hot bending film is as figure 1 As shown, it includes a pressure-sensitive adhesive layer (1), a first PET resin film (2), a composite OCA adhesive layer (3), a second PET resin film (4) and a hardened layer (5) from bottom to top. The shrinkage rate of the PET resin film in the PET resin film layer is 0.5%.

[0076] Among them, the thickness of the pressure-sensitive adhesive layer is 20 μm, the thickness of the first PET resin film is 30 μm, the thickness of the composite OCA adhesive layer is -20 μm, the thickness of the second PET resin film is 20 μm, and the thickness of the hardened layer is 5 μm.

[0077] The pressure-sensitive adhesive layer is an organic silicon pressure-sensitive adhesive layer, and the raw materials of the composite OCA adhesive layer are silicone resin, a flexibilizer, a hardness regulator, a tackifier and an antistatic agent, a PET resin film and a pressure-sensitive adhesive layer, and The hardened...

Embodiment 2

[0080] In this embodiment, the structure of the hot bending film is as figure 1 As shown, it includes a pressure-sensitive adhesive layer (1), a first PET resin film (2), a composite OCA adhesive layer (3), a second PET resin film (4) and a hardened layer (5) from bottom to top. The shrinkage rate of the PET resin film in the PET resin film layer is 0.4%.

[0081] Among them, the thickness of the pressure-sensitive adhesive layer is 10 μm, the thickness of the first PET resin film is 50 μm, the thickness of the composite OCA adhesive layer is 15 μm, the thickness of the second PET resin film is 40 μm, and the thickness of the hardened layer is 10 μm.

[0082] The pressure-sensitive adhesive layer is an organic silicon pressure-sensitive adhesive layer, and the raw materials of the composite OCA adhesive layer are silicone resin, a flexibilizer, a hardness regulator, a tackifier and an antistatic agent, a PET resin film and a pressure-sensitive adhesive layer, and The hardened l...

Embodiment 3

[0085] In this embodiment, the structure of the hot bending film is as figure 1 As shown, it includes a pressure-sensitive adhesive layer (1), a first PET resin film (2), a composite OCA adhesive layer (3), a second PET resin film (4) and a hardened layer (5) from bottom to top. The shrinkage rate of the PET resin film in the PET resin film layer is 0.5%.

[0086] Among them, the thickness of the pressure-sensitive adhesive layer is 40 μm, the thickness of the first PET resin film is 20 μm, the thickness of the composite OCA adhesive layer is 10 μm, the thickness of the second PET resin film is 20 μm, and the thickness of the hardened layer is 3 μm.

[0087] The pressure-sensitive adhesive layer is an organic silicon pressure-sensitive adhesive layer, and the raw materials of the composite OCA adhesive layer are silicone resin, a flexibilizer, a hardness regulator, a tackifier and an antistatic agent, a PET resin film and a pressure-sensitive adhesive layer, and The hardened ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com