A kind of hot bending film for radian screen

A technology of curvature and film layer, which is applied in the field of hot bending film for curved screens, can solve the problems that PET flat film cannot be bonded, the screen is easily broken or scratched, and cannot be exported, and achieves good wear resistance and scratch resistance. Good, to avoid the effect of film warping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

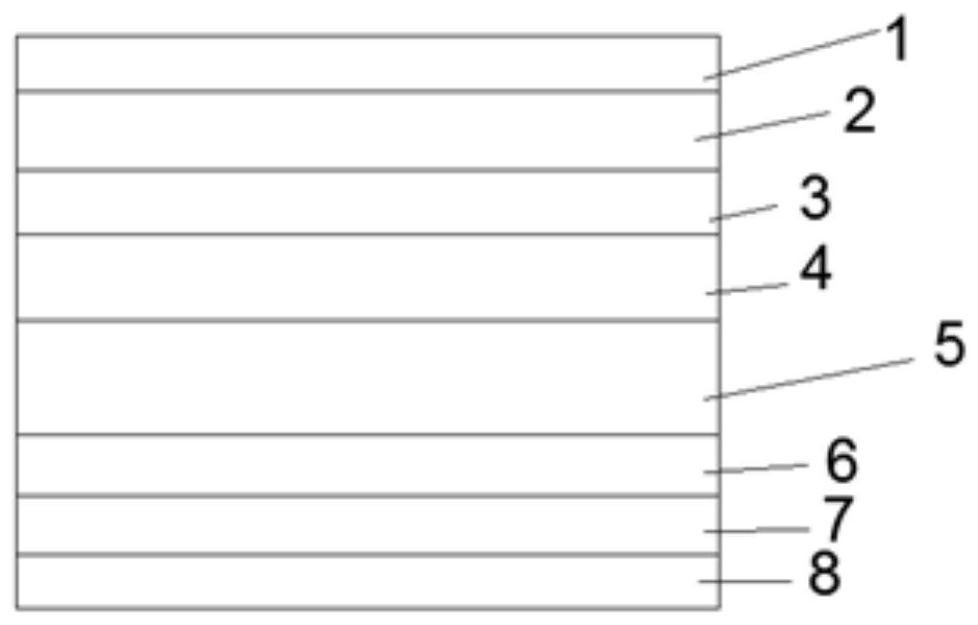

[0030] As an embodiment of a heat bending film for a curved screen of the present invention, the structure of the heat bending film is as follows figure 1 As shown, it includes the first protective film 1, the silica gel layer 2, the first PET resin film layer 3, the OCA adhesive layer 4, the thermosetting acrylic resin film layer 5, the second PET resin film layer 6, and the hardened layer 7 from bottom to top. and the second protective film 8;

[0031] Wherein, the thickness of the first protective film 1 is 50 μm, the thickness of the silica gel layer 2 is 25 μm, the thickness of the first PET resin film layer 3 is 5 μm, the thickness of the OCA adhesive layer 4 is 30 μm, and the thickness of the thermosetting acrylic resin film layer 5 is The thickness of the second PET resin film layer 6 is 25 μm, the thickness of the cured layer 7 is 3 μm, and the thickness of the second protective film 8 is 50 μm.

[0032] Among them, the peel strength of the first protective film is 0...

Embodiment 2

[0036] As an embodiment of a heat bending film for a curved screen of the present invention, the structure of the heat bending film is as follows figure 1 As shown, it includes the first protective film 1, the silica gel layer 2, the first PET resin film layer 3, the OCA adhesive layer 4, the thermosetting acrylic resin film layer 5, the second PET resin film layer 6, and the hardened layer 7 from bottom to top. and the second protective film 8;

[0037] Wherein, the thickness of the first protective film 1 is 50 μm, the thickness of the silica gel layer 2 is 50 μm, the thickness of the first PET resin film layer 3 is 15 μm, the thickness of the OCA adhesive layer 4 is 40 μm, and the thickness of the thermosetting acrylic resin film layer 5 is The thickness of the second PET resin film layer 6 is 50 μm, the thickness of the cured layer 7 is 3 μm, and the thickness of the second protective film 8 is 50 μm.

[0038] Wherein, the peel strength of the first protective film is 0.5...

Embodiment 3

[0042] As an embodiment of a heat bending film for a curved screen of the present invention, the structure of the heat bending film is as follows figure 1 As shown, it includes the first protective film 1, the silica gel layer 2, the first PET resin film layer 3, the OCA adhesive layer 4, the thermosetting acrylic resin film layer 5, the second PET resin film layer 6, and the hardened layer 7 from bottom to top. and the second protective film 8;

[0043]Wherein, the thickness of the first protective film 1 is 50 μm, the thickness of the silica gel layer 2 is 75 μm, the thickness of the first PET resin film layer 3 is 15 μm, the thickness of the OCA adhesive layer 4 is 50 μm, and the thickness of the thermosetting acrylic resin film layer 5 is The thickness of the second PET resin film layer 6 is 75 μm, the thickness of the hardened layer 7 is 3 μm, and the thickness of the second protective film 8 is 50 μm.

[0044] Among them, the peel strength of the first protective film i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com