Hot-bending-free photo-curing curved screen protective sticker

A light-curing, curved screen technology, used in chemical instruments and methods, film/sheet adhesives, synthetic resin layered products, etc. problem, to achieve the effect of firm fit, good scratch resistance and good transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

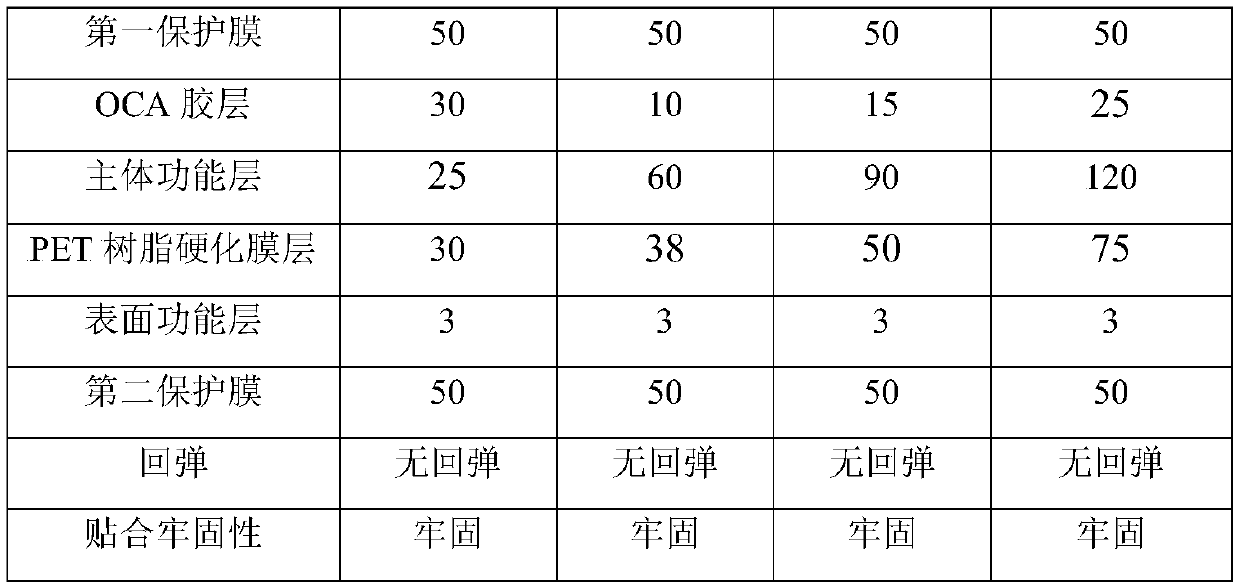

[0017] In this embodiment, the structure of the heat-free curved light curing curved screen protector includes a first protective film, an OCA adhesive layer, a main functional layer, a PET resin cured film layer, a surface functional layer and a second protective film from bottom to top. Laminate each layer according to the structure to obtain a heat-free bending light curing curved screen protector, which can be made into the target product after die-cutting, laminating, curing and other processes. The first protective film is an acrylic protective film, and the second protective film is a silicone protective film. The thickness of each film is shown in Table 1.

[0018] Among them, the main functional layer contains thermosetting acrylic resin, isocyanate, polyoxyethylene polyoxypropanolamine ether defoamer, 1073 leveling agent of Moeneng Chemical, and methyl hydroxyethyl cellulose thickener. The mass of isocyanate accounts for 25% of the mass of thermosetting acrylic resi...

Embodiment 2

[0024] In this embodiment, the structure of the heat-free curved light curing curved screen protector includes a first protective film, an OCA adhesive layer, a main functional layer, a PET resin cured film layer, a surface functional layer and a second protective film from bottom to top. Laminate each layer according to the structure to obtain a heat-free bending light curing curved screen protector, which can be made into the target product after die-cutting, laminating, curing and other processes. The first protective film is an acrylic protective film, and the second protective film is a silicone protective film. The thickness of each film is shown in Table 1.

[0025] Among them, the main functional layer contains thermosetting acrylic resin, isocyanate, polyoxypropylene glyceryl ether defoamer, Moeneng Chemical 1074 leveling agent, and hydroxyethyl cellulose thickener. The mass of isocyanate accounts for 3% of the mass of thermosetting acrylic resin; the mass of defoame...

Embodiment 3

[0030] In this embodiment, the structure of the heat-free curved light curing curved screen protector includes a first protective film, an OCA adhesive layer, a main functional layer, a PET resin cured film layer, a surface functional layer, and a second protective film from bottom to top. Laminate each layer according to the structure to obtain a heat-free bending light curing curved screen protector, which can be made into the target product after die-cutting, laminating, curing and other processes. The first protective film is an acrylic protective film, and the second protective film is a silicone protective film. The thickness of each film is shown in Table 1.

[0031] Among them, the main functional layer contains thermosetting acrylic resin, isocyanate, polyoxypropylene glyceryl ether defoamer, 1074 leveling agent of Moeneng Chemical, and polyurethane thickener. The mass of isocyanate accounts for 45% of the mass of thermosetting acrylic resin; the mass of defoamer acc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com