Tire tread and preparation method thereof

A tire tread and tread technology, applied in special tires, tire parts, rolling resistance optimization, etc., can solve problems such as use restrictions, and achieve the effects of reducing rolling resistance, increasing modulus, and improving wear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

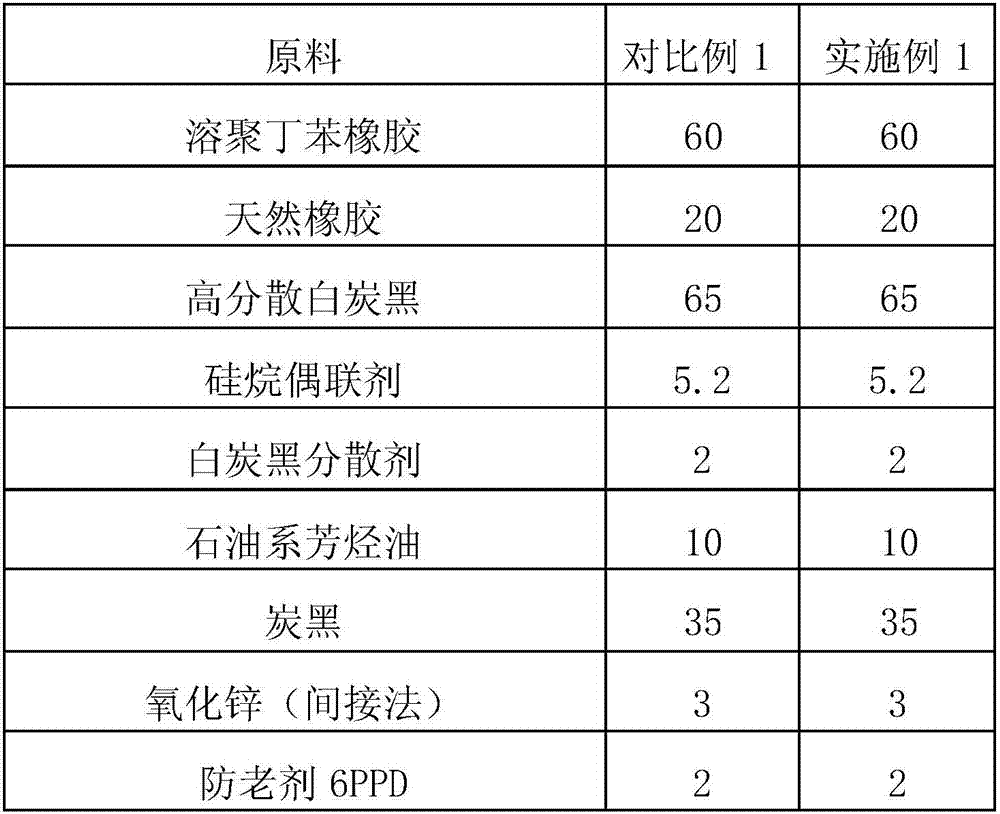

[0013] A tire tread, said tread comprising: 1-60 parts of solution-polymerized styrene-butadiene rubber, 1-40 parts of natural rubber, 1.5 parts of environment-friendly accelerator, 10-100 parts of highly dispersed white carbon black, 1-8 parts Silane coupling agent, 10-50 parts of carbon black, and 1-20 parts of petroleum aromatic oil.

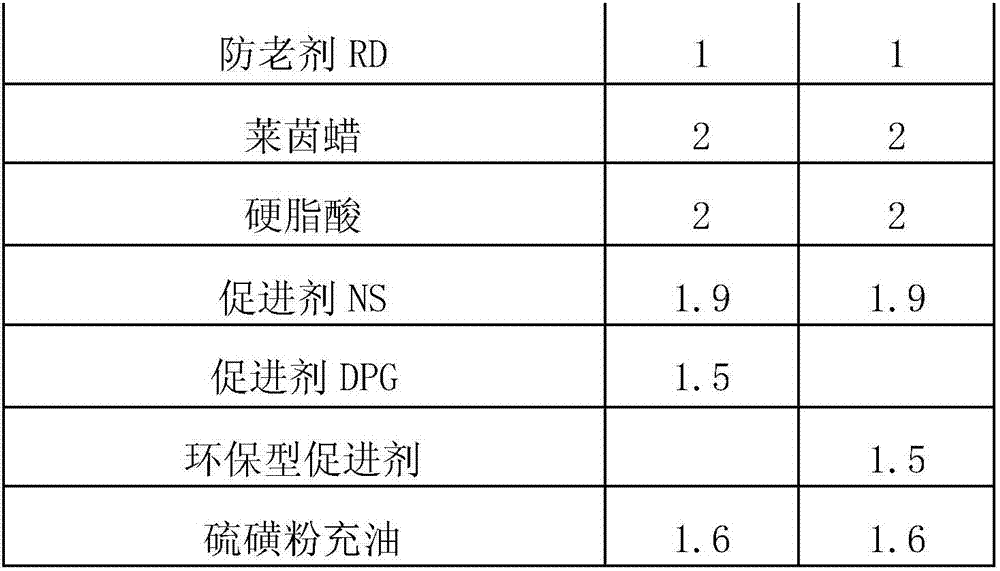

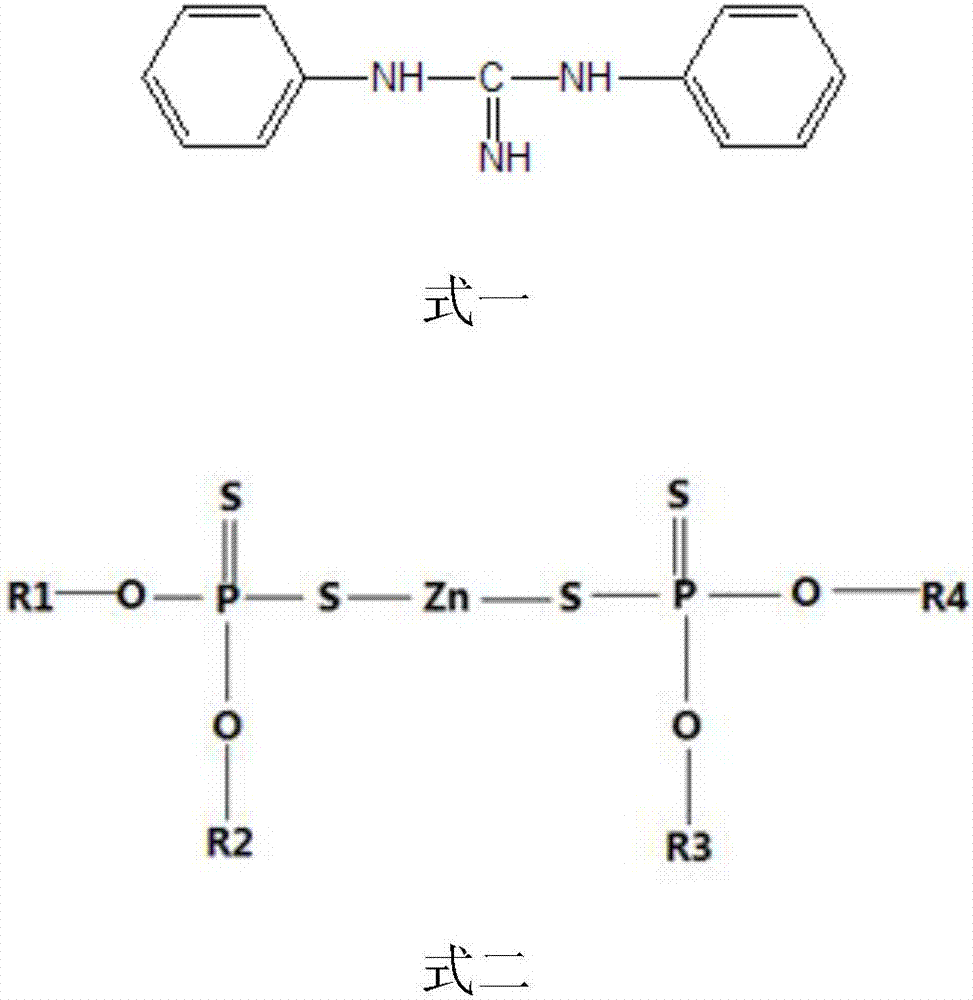

[0014] Wherein, the environment-friendly accelerator is a compound of zinc dialkyl dithiophosphate and a carrier.

[0015] In the solution-polymerized styrene-butadiene rubber, styrene is 0-60%, the vinyl content accounts for 10%-70%, and the Tg point is -10°C--50°C;

[0016] The natural rubber is a polymer of 1,4-cis polyisoprene;

[0017] The nitrogen adsorption specific surface area of the highly dispersed white carbon black is 120-200m 2 / g, can directly or indirectly combine with rubber molecules physically and chemically;

[0018] The silane coupling agent is a sulfur-containing organosilicon compound with functional groups;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com